High-temperature behavior stable modified emulsified asphalt and method for preparing the same

A high-temperature performance, emulsified asphalt technology, applied in building insulation materials, building components, construction, etc., can solve the problems of complex production process, increase the viscosity of asphalt, affect the stability of emulsion, etc., and achieve simple production process, stable high-temperature performance, high performance superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

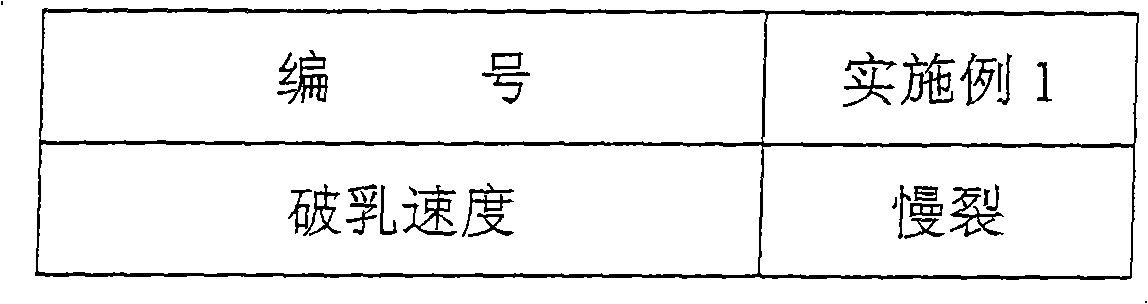

Embodiment 1

[0038] formula:

[0039] Based on the weight of base asphalt, the mixture of phosphorus compounds is 5%, the compound emulsifier is 0.5%, the modifier latex is 10%; ferric chloride is 0.01%;

[0040] The mixture component and weight percent of phosphorus-containing compound are:

[0041] Polyphosphoric acid 35%

[0042] Pyrophosphate 30%

[0043] Phosphoric acid 35%

[0044] The weight concentration of described polyphosphoric acid is 105% (with H 3 PO 4 remember).

[0045] Component and weight percent of described composite emulsifier are:

[0046] Cocamidopropyl Betaine 25%

[0047] Octadecylmethylammonium Chloride 10%

[0048] Water 65%

[0049] Preparation:

[0050] (1) Heating the base asphalt to 120°C, putting in a mixture of phosphorus-containing compounds, stirring and mixing to obtain phosphating modified asphalt;

[0051] (2) Put the phosphating modified asphalt at a temperature of 120° C. into the modifier latex, stir and mix to obtain the asphalt latex; ...

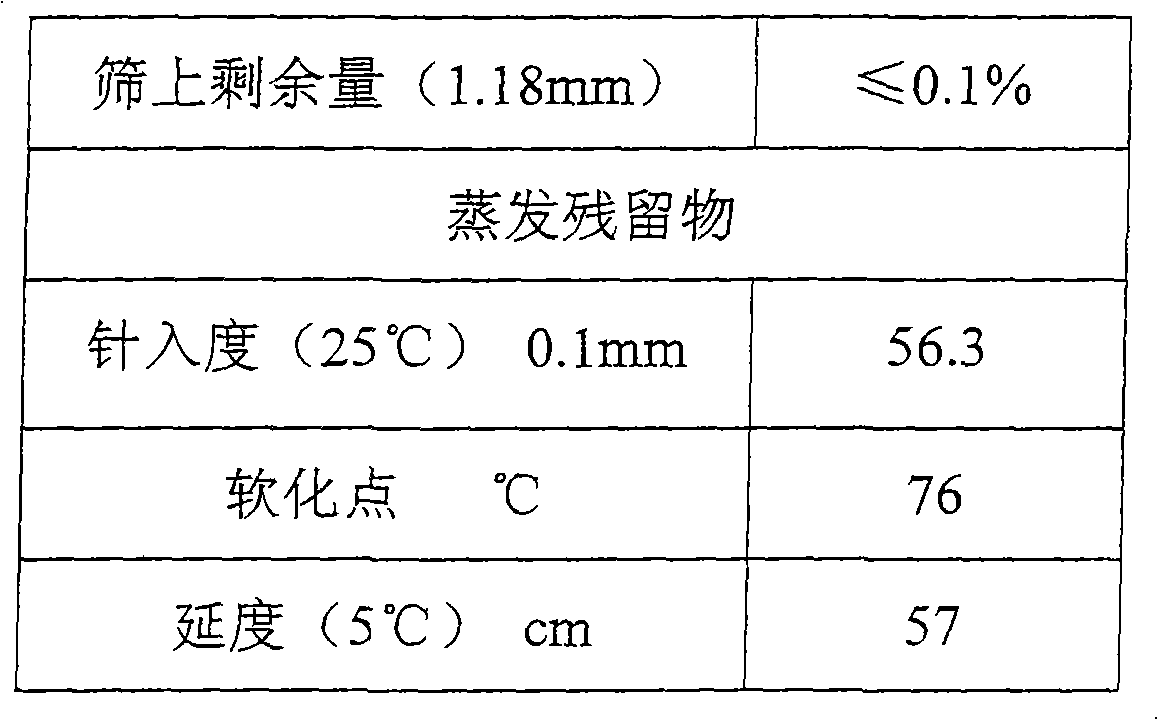

Embodiment 2

[0058] formula:

[0059] Based on the weight of base asphalt, the mixture of phosphorus compounds is 0.1%, the compound emulsifier is 5%, the modifier latex is 1%; polyvinyl alcohol is 2%

[0060] The mixture component and weight percent of phosphorus-containing compound are:

[0061] Polyphosphoric acid 40%

[0062] Pyrophosphate 20%

[0063] Phosphoric acid 40%

[0064] The weight concentration of described polyphosphoric acid is 105% (with H 3 PO 4 remember).

[0065] Component and weight percent of described composite emulsifier are:

[0066] Cocamidopropyl Betaine 30%

[0067] Octadecylmethylammonium Chloride 5%

[0068] Water 65%

[0069] Preparation:

[0070] (1) Heat the base asphalt to 180°C, put in the mixture of phosphorus-containing compounds, stir and mix to obtain phosphating modified asphalt;

[0071] (2) Put the phosphating modified asphalt at a temperature of 180° C. into the modifier latex, stir and mix to obtain the asphalt latex;

[0072] (3) St...

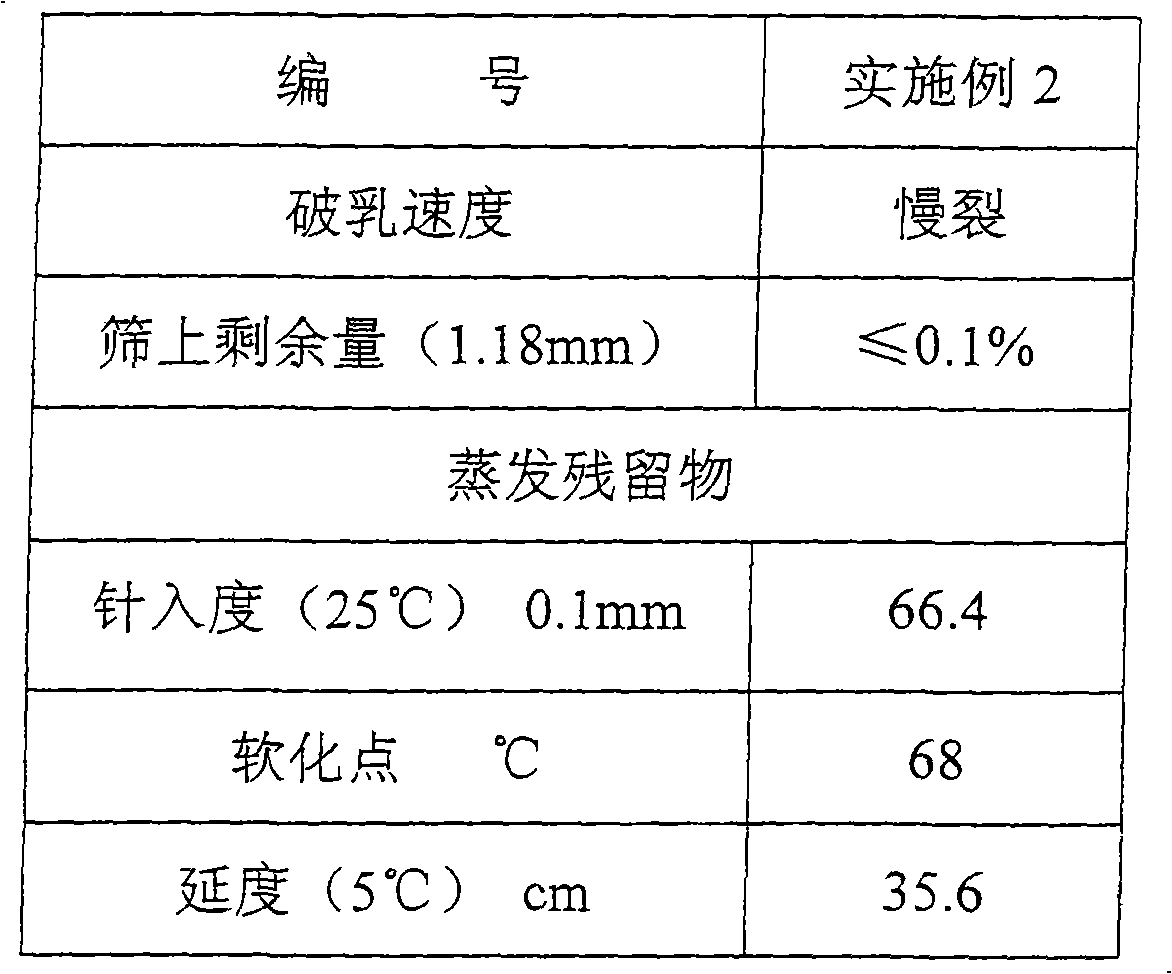

Embodiment 3

[0077] Others are the same as embodiment 1, wherein:

[0078] Stabilizer is calcium chloride; Component and weight percent of described composite emulsifier are:

[0079] Cocamidopropyl Betaine 30%

[0080] Octadecylmethylammonium Chloride 10%

[0081] water 60%

[0082] The asphalt test was carried out in accordance with the standards of the Ministry of Communications of China, "Asphalt and Asphalt Mixture Test Regulations" JTJ052-2000, and the performance indicators of the modified emulsified asphalt were measured. The results are as follows:

[0083]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com