Code-jet printing ink modifier

A modifier and ink technology, applied in inks, household appliances, applications, etc., can solve the problems that affect the drying speed of the ink and the friction resistance of the image, affect the printing quality and efficiency of the coding ink, and affect the efficiency and quality of printing. Achieve the effect of improving imaging effect, strong friction resistance and preventing droplets

Inactive Publication Date: 2013-05-01

BEIJING KEYIN MODERN PRINTING TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of the current Kuaiyu type ink is that it is easy to block the pipeline and the nozzle, which seriously affects the printing efficiency and quality.

Previous researches have added polymer wetting agents to solve the clogging problem, but the addition of polymer wetting agents will affect the volatility of the ink, thereby affecting the drying speed of the ink and the friction resistance of the image. This problem has always affected the inkjet code. Ink printing quality and efficiency

There are currently no studies specifically addressing adhesion to metal substrates

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

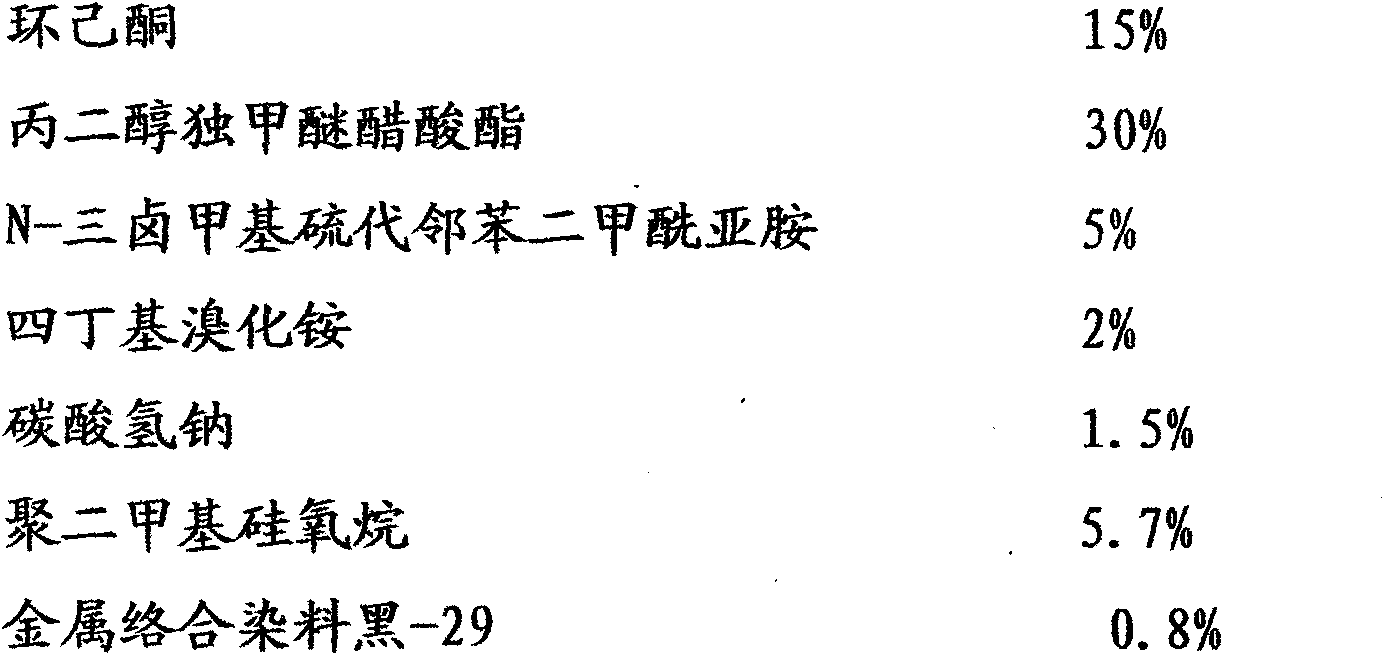

Embodiment 1

[0029] A kind of inkjet ink modifier, is made up of following component and content

[0030]

[0031]

[0032] All percentages are by weight

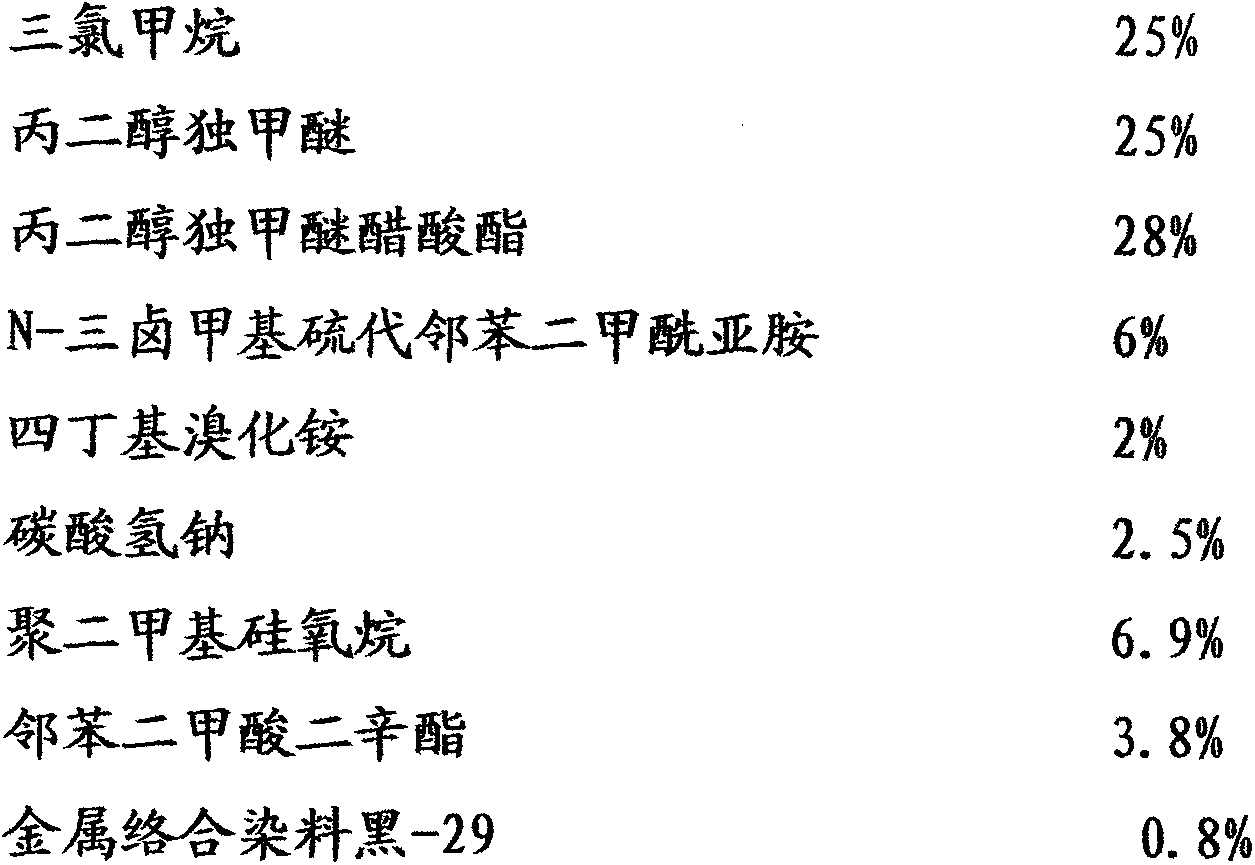

Embodiment 2

[0034] A kind of inkjet ink modifier, is made up of following component and content

[0035]

[0036] All percentages are by weight

Embodiment 3

[0038] A kind of inkjet ink modifier, is made up of following component and content

[0039]

[0040] All percentages are by weight

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a code spraying ink modifying agent which comprises the components with weight percentage: 20-60wt% of solvent, 10-40wt% of latent solvent, 1-10wt% of anticoagulant, 1-10wt% of electrical conduction control agent, 0.1-6wt% of pH conditioning agent, 5-15wt% of adhesive force promoting agent, 0.1-4wt% of osmotic agent, 0.5-9wt% of stabilizing agent and 0.1-5wt% of coloring agent. The anticoagulant and the latent solvent contained in the code spraying ink modifying agent can effectively improve the phenomenon that a nozzle is easy to plug by code spraying ink, and ensures the code spraying ink to be dried rapidly and print more clearly and smoothly; the contained adhesive force promoting agent can be used for strengthening the adhesiveness of the code spraying ink for base material, especially metal base material, so as to lead the image to be firmer and hard wearing. Various auxiliary agents in the invention are matched for use, so that the performance of the code spraying ink can be effectively enhanced, the image resolution ratio is improved, the separation of ink dots is clear, the problem of trickling and deforming of the ink can be solved, and the corrosion resistance is improved.

Description

technical field [0001] The invention relates to a printing ink modifier, in particular to a modifier for inkjet ink, which is mainly used to improve various application performances of inkjet ink. Background technique [0002] During the use of inkjet ink, the ink is continuously inkjet printed on various substrate media to form graphics, codes, letters, dates and other marks. In this process, it is required that the inkjet ink can be printed on the medium continuously, uniformly, clearly and firmly. For this reason, there are high requirements for ink viscosity, volatility, adhesion performance, acidity and alkalinity, and conductivity. [0003] Existing inkjet inks can be divided into fast-drying inks, medium-drying inks and slow-drying inks. With the improvement of printing efficiency, fast-drying inks have been widely used. The disadvantage of the current Kuaiyu type ink is that it is easy to block the pipeline and the nozzle, which seriously affects the printing effic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D11/02C09D7/00C09D11/30C09D11/36C09D11/38

Inventor 刘金英赵丽娟李红霞

Owner BEIJING KEYIN MODERN PRINTING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com