Residual heat comprehensive utilization method for carbon calciner

A calciner, waste heat technology, applied in furnaces, waste heat treatment, steam superheating and other directions, can solve the problems of high exhaust gas temperature, non-compliance with energy saving and emission reduction policies, energy waste and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

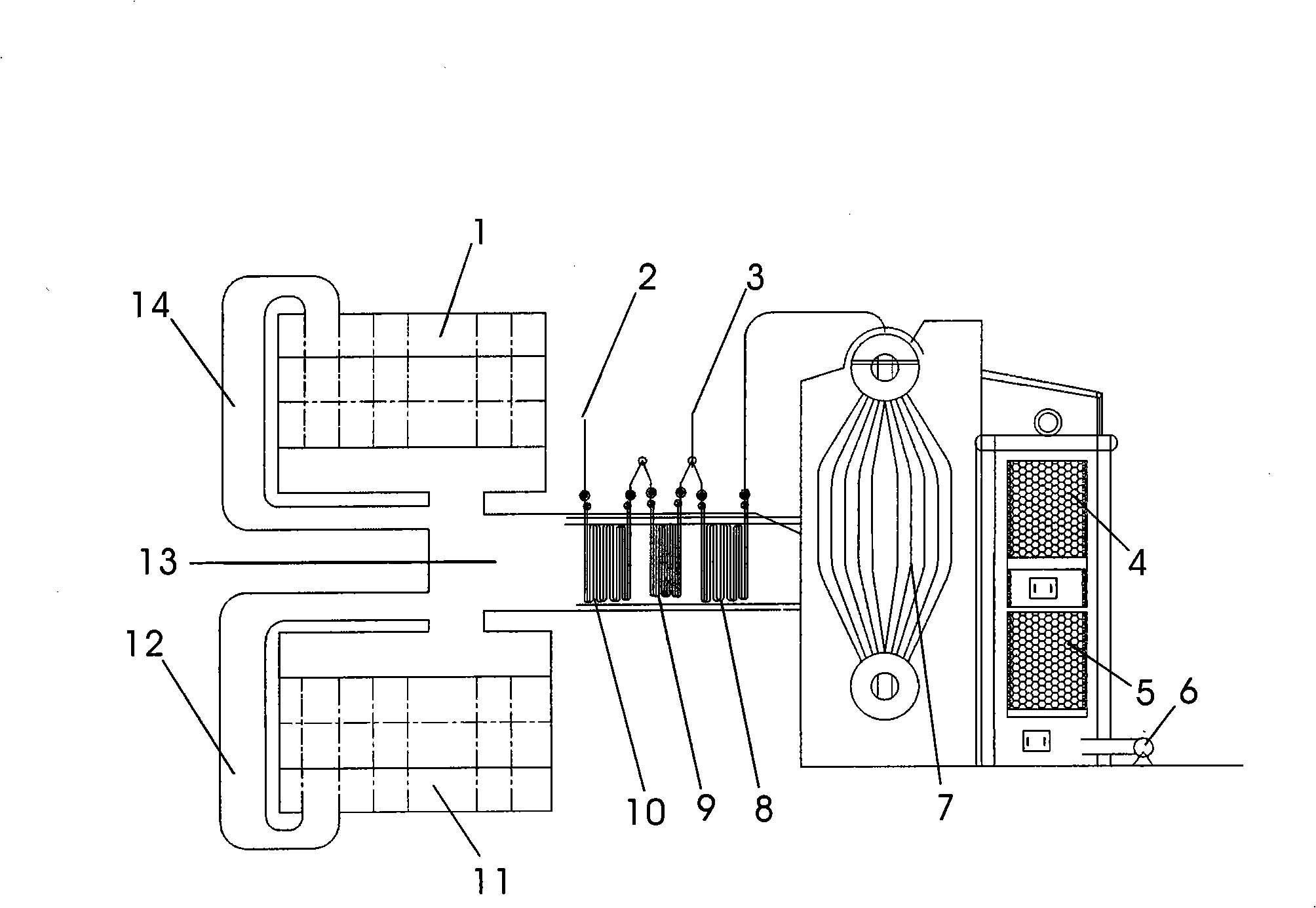

[0054] Now refer to the attached figure 1 , the method for comprehensive utilization of waste heat of carbon calciner of the present invention is described in detail as follows in conjunction with embodiment: the method for comprehensive utilization of waste heat of carbon calciner of the present invention, the high-temperature flue gas that calciner 8 layers of fire channels produce and The high-temperature flue gas formed by the unique "external combustion of excess volatile matter in the first layer" of this device is integrated into the integrated waste heat boiler, and the saturated steam formed by the waste heat boiler is sent back to the superheated steam generator at the high-temperature flue gas at the outlet of the calciner to form The superheated steam that satisfies power generation and heat supply is used for power generation and heat supply. The volatile matter of petroleum coke is used for heating, and the discharge rate of each tank is 90kg / h. A total of 160 ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com