Heat pipe performance detection device

A detection device and heat pipe technology, applied in the direction of material thermal development, material thermal conductivity, etc., can solve the problems of inability to meet the detection requirements of mass production process, delayed delivery, unfavorable heat pipe performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

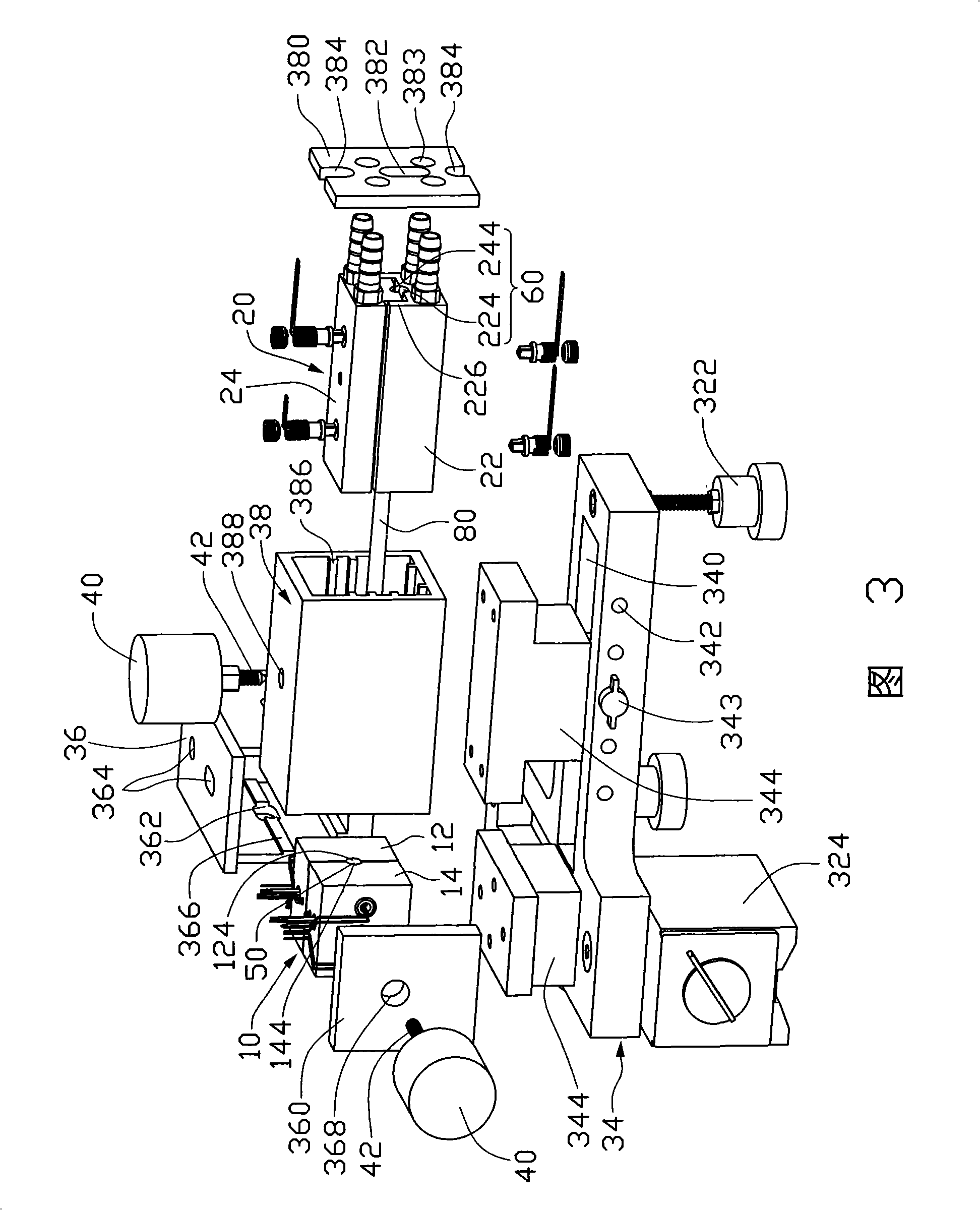

[0029] The heat pipe performance detection device of the present invention will be further described below with reference to FIGS. 2 to 10 .

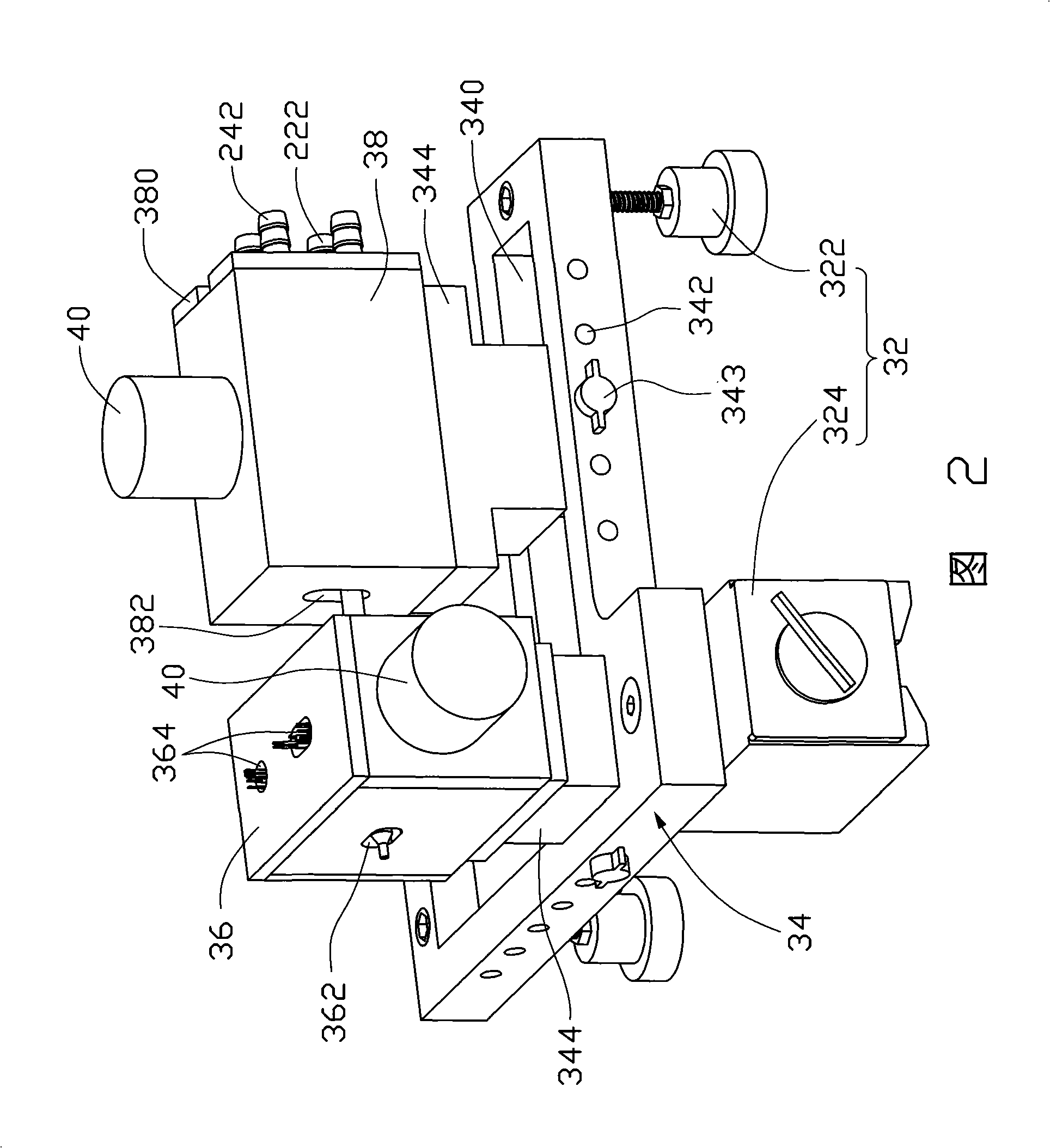

[0030] Fig. 2 is a three-dimensional schematic diagram of the appearance of the first embodiment of the heat pipe performance detection device of the present invention, Fig. 3 is a three-dimensional exploded schematic diagram of Fig. 2, and Fig. 4 is a three-dimensional exploded schematic diagram of the heating assembly in Fig. 2; the detection device mainly includes a The heating element 10 , a heat dissipation element 20 and a bearing seat 30 . in:

[0031]The heating assembly 10 includes a fixed part 12 and a movable part 14 arranged side by side in a horizontal direction. A moving part that can move linearly. At least one of the fixed part 12 and the movable part 14 is made of a material with good thermal conductivity. In this embodiment, both are made of a material with good thermal conductivity as an example. Wherein, at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com