Solar energy continuous heat supply type drying apparatus

A technology of drying equipment and solar energy, applied in applications, food processing, food science, etc., can solve the problems of high cost, increased drying room space, complex structure, etc., and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

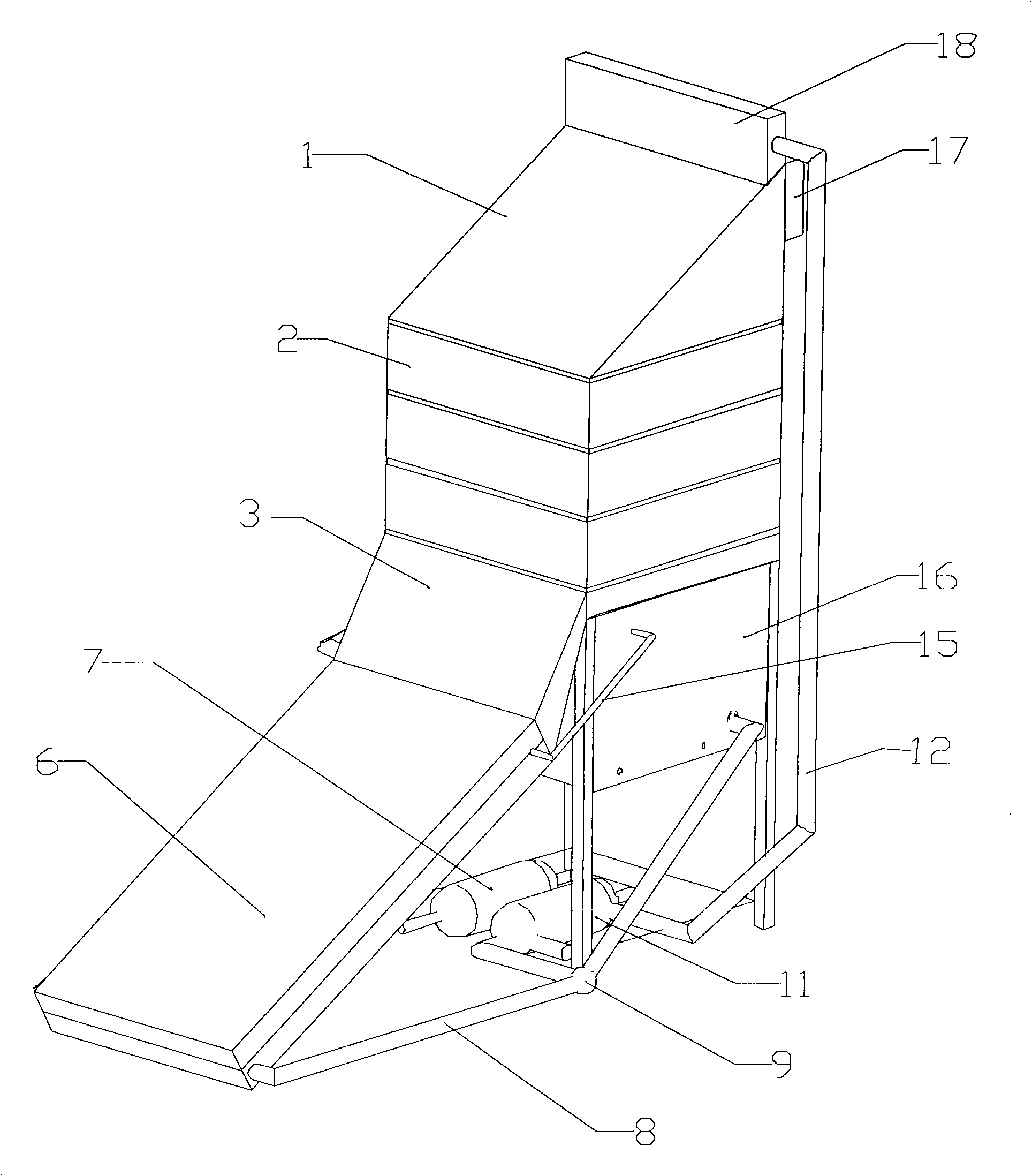

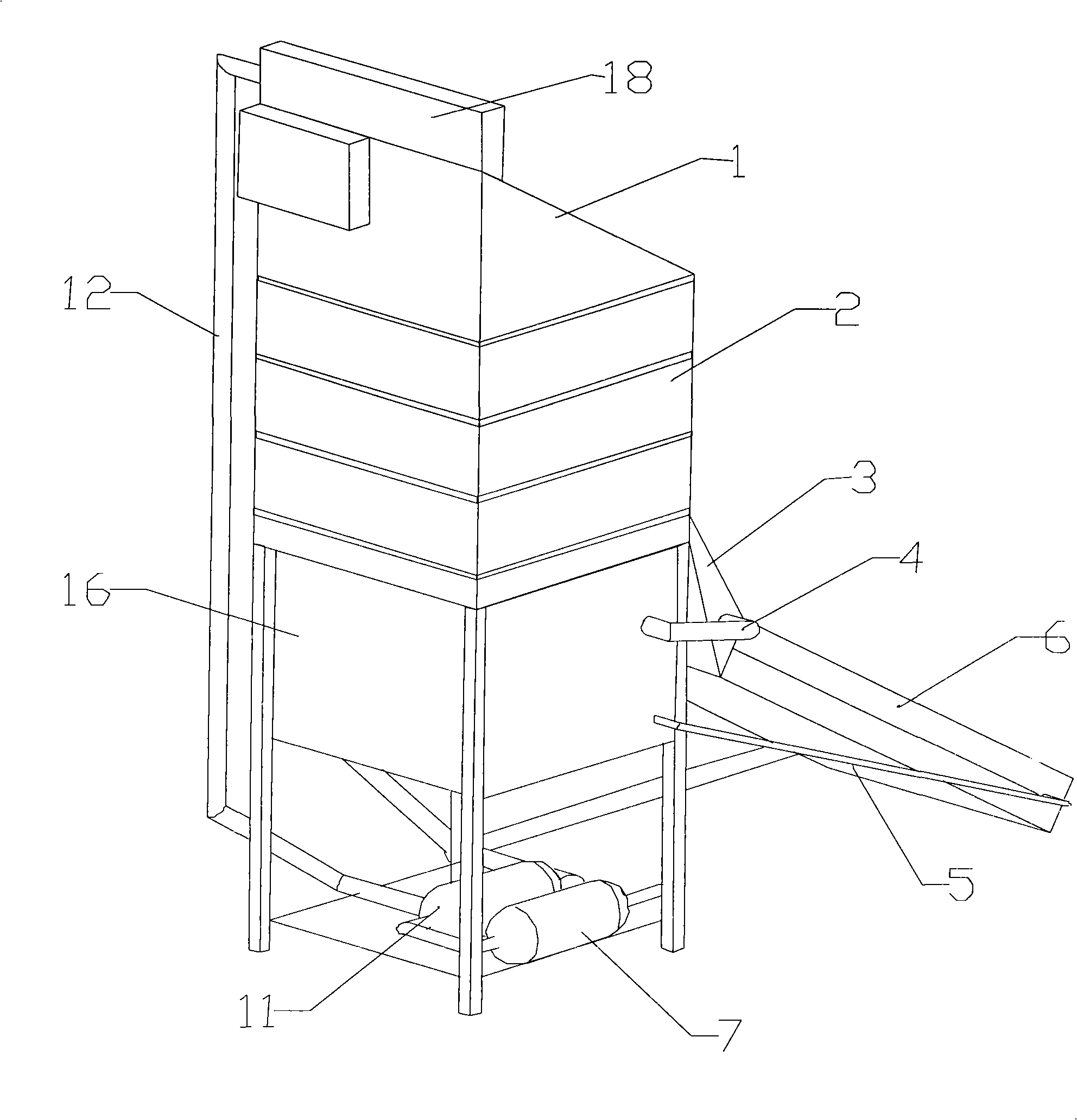

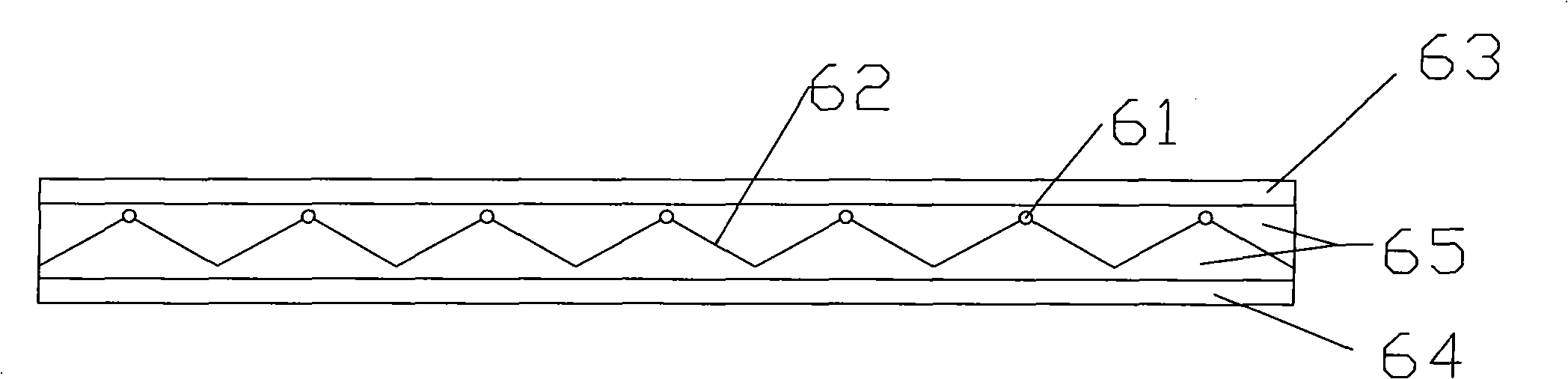

[0022] The invention relates to a solar energy continuous heating type drying equipment, capable of continuous heating, low in cost, simple in structure and high in heat utilization efficiency. figure 1 It is a schematic diagram of the three-dimensional structure of the present invention, figure 2 It is a schematic diagram of the back three-dimensional structure of the present invention; the present invention includes a drying chamber 1, a material frame 2, a drying chamber air inlet interface 3, a first air duct 8, a second air duct 4, a third air duct 12, a first water pipe 5, Second water pipe 15, V-plate heat collector 6, blower 7, control valve 9, heat exchanger 11, electric heating wire 13, serpentine pipe 14, thermal insulation water tank 16, temperature and humidity sensor 17, exhaust chimney 18 .

[0023] The drying chamber 1 of the present invention is provided with a material frame 2. In order to save space and improve heat utilization, the material frame 2 is sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com