Straight through cement mixer

A technology of agitator and mixing chamber, which is applied in the direction of cement mixing device, fluid mixer, chemical instrument and method, etc. It can solve the problems of complexity, short equipment life, corrosion of dirty mixing water, etc., and achieve compact structure and low production cost , easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

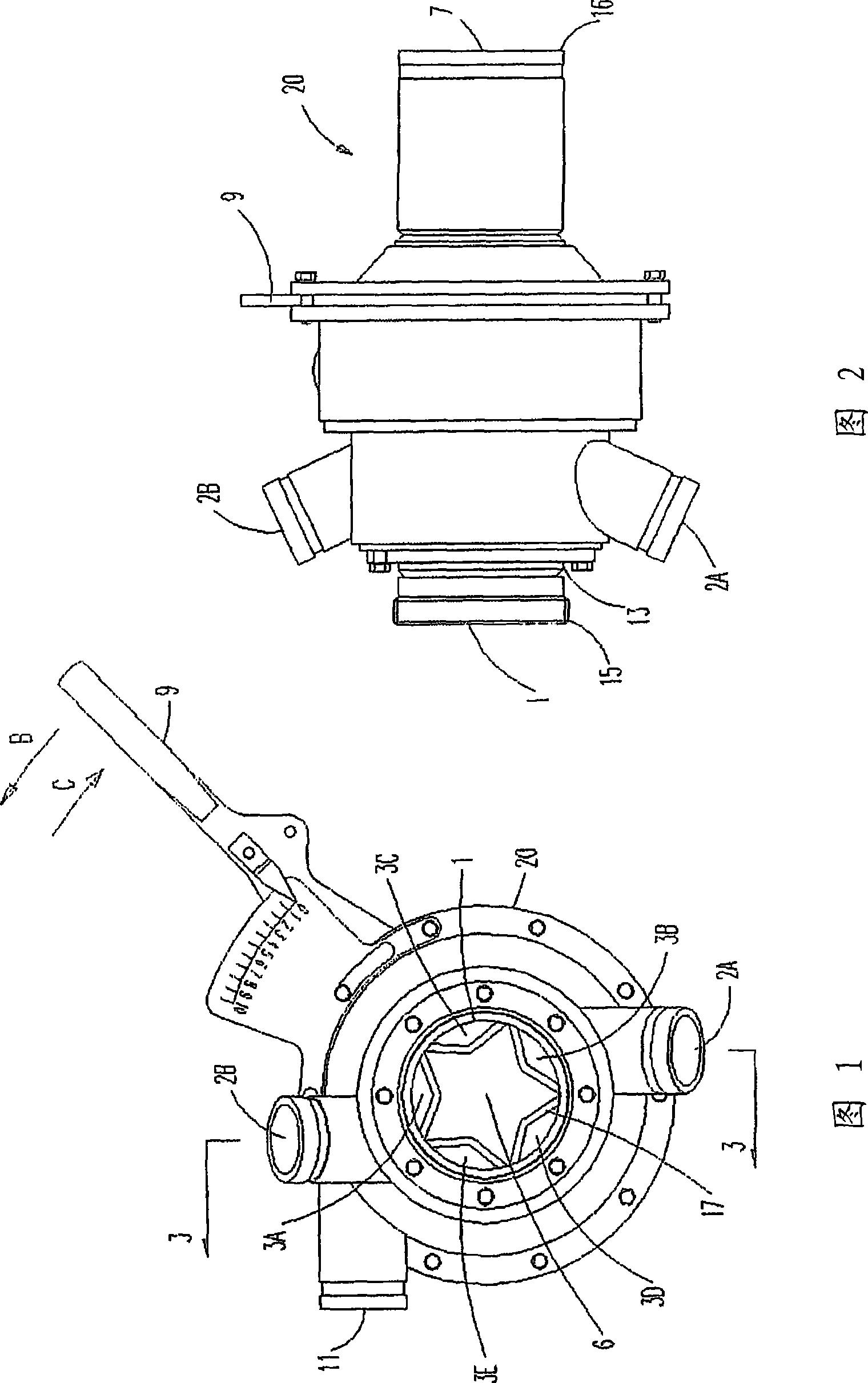

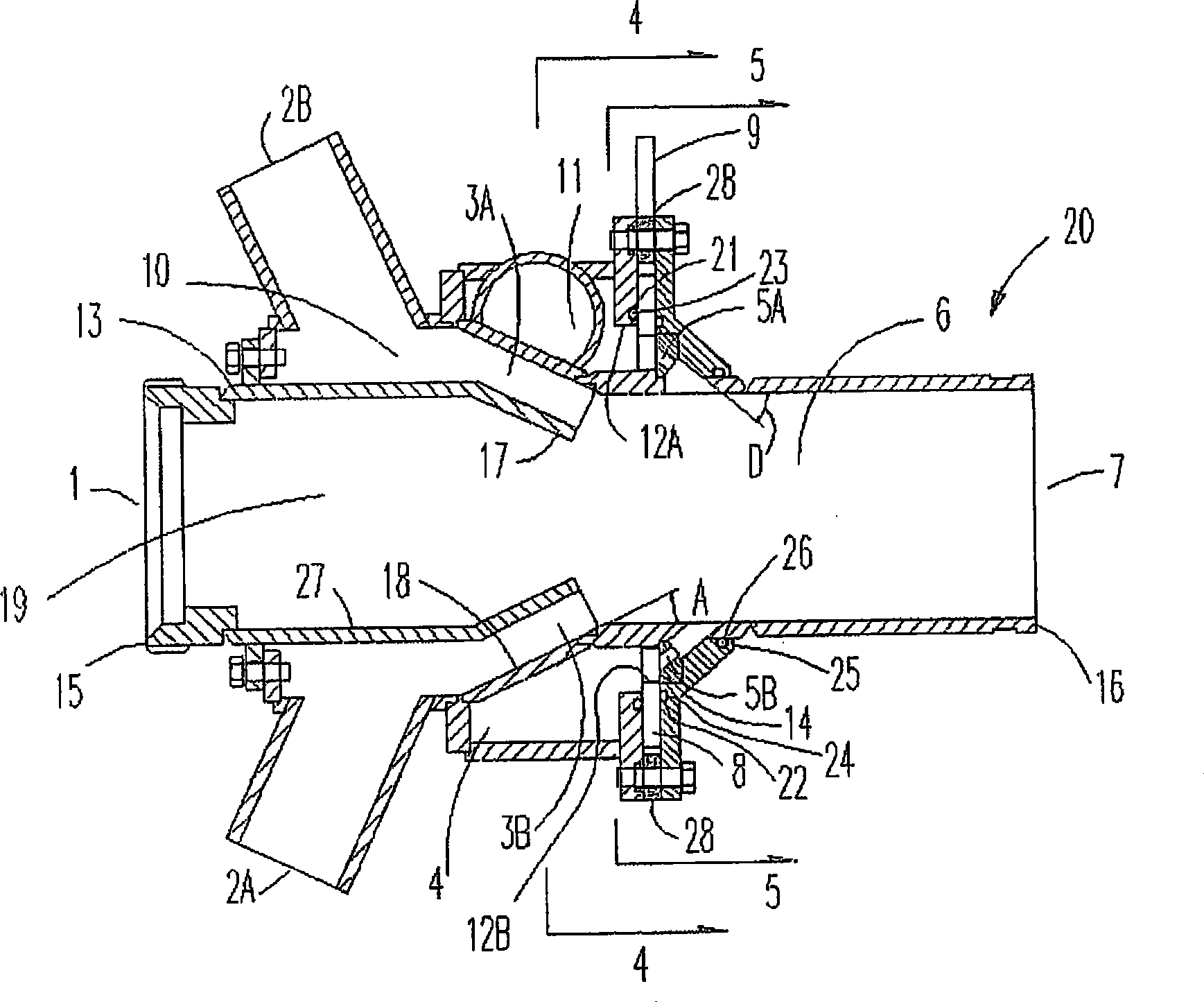

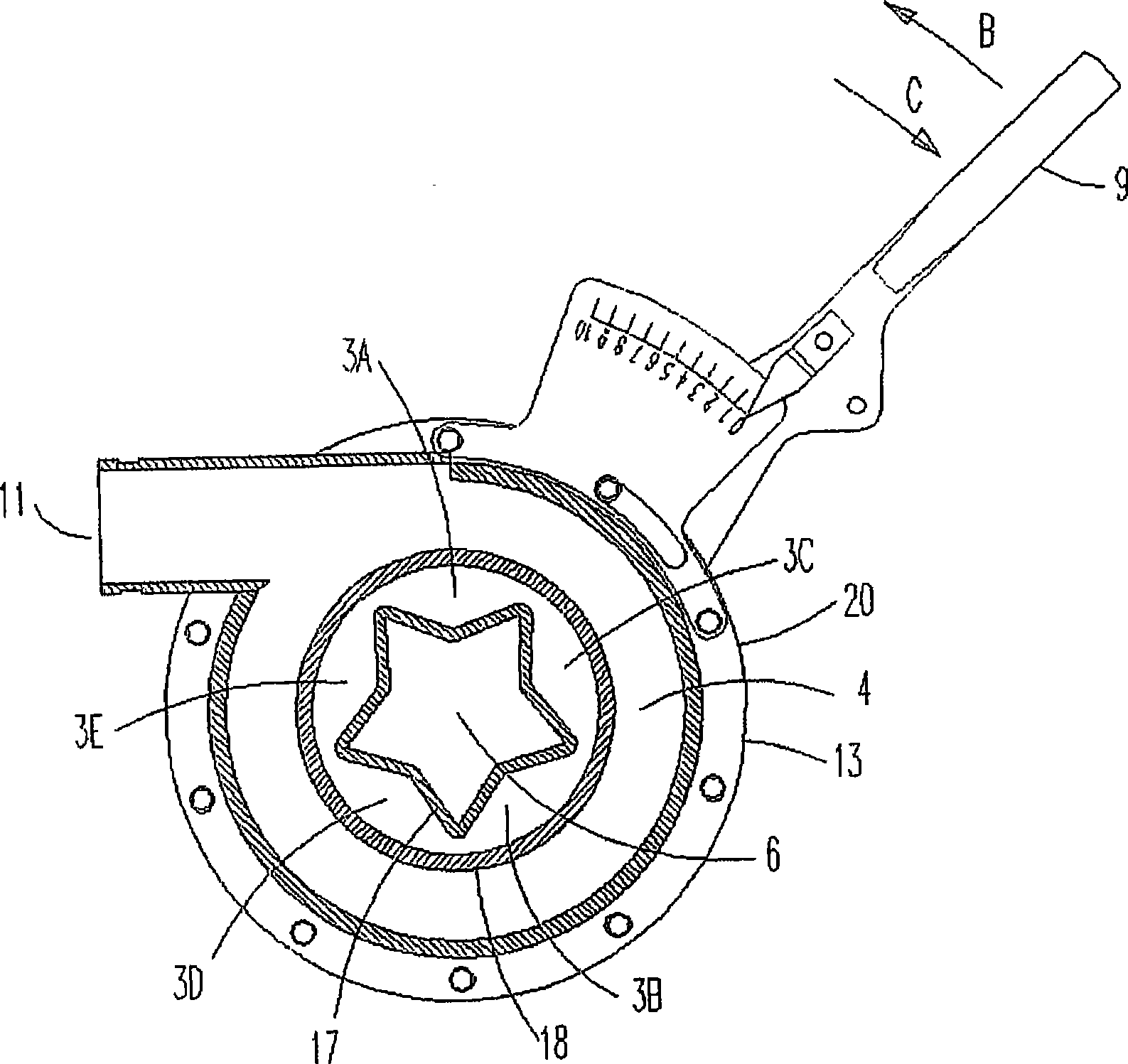

[0034] Referring to the attached drawings, first of all figure 2 with 3 , the present invention relates to a cement mixing method and a mixer 20 for mixing cement in the method, and the stirred cement will be used for oil well cement grouting. A generally exemplary system and apparatus is taught in US Patent No. 6,749,330, in which an agitator 20 is used. This teaching is hereby incorporated by reference.

[0035] As detailed in US Patent No. 6,749,330, a typical cement mixer discharges from its outlet end into a diffuser and then into a mixing tank. A recirculation pump is connected to the agitation tank and recirculates the contents of the agitation tank to a recirculation fluid inlet provided on the agitator. And, generally, the stirring water pump is connected to the stirring water supplier and pumps the stirring water to the stirring water inlet provided on the stirrer. In addition, bulk cement is pneumatically conveyed to the dry bulk cement inlet on the mixer. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com