Method and equipment for emulsifying fuel liquid

A liquid fuel and fuel technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of high price and increased cost, and achieve the goals of reducing pollution, saving diesel oil, reducing economic and social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

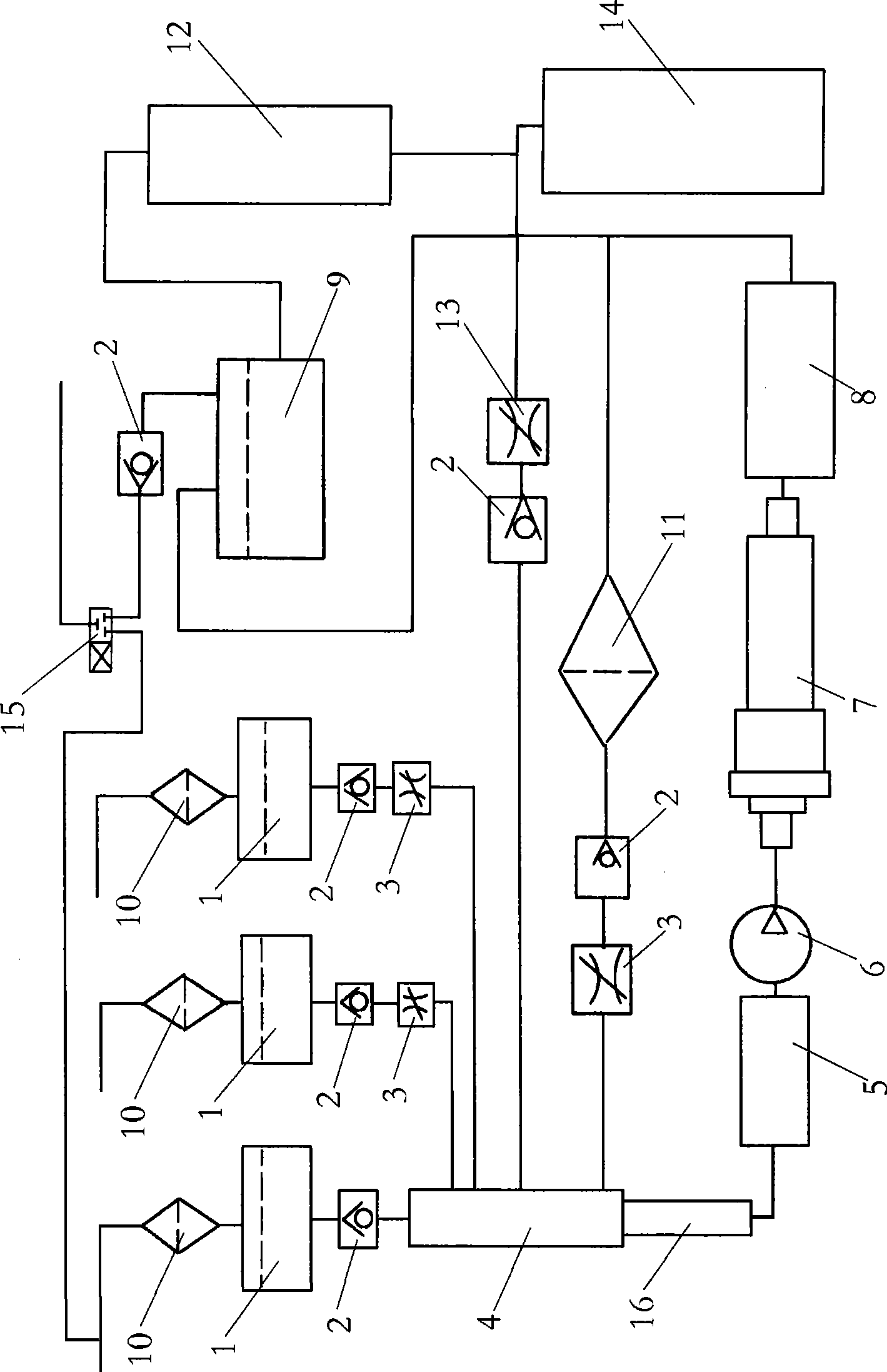

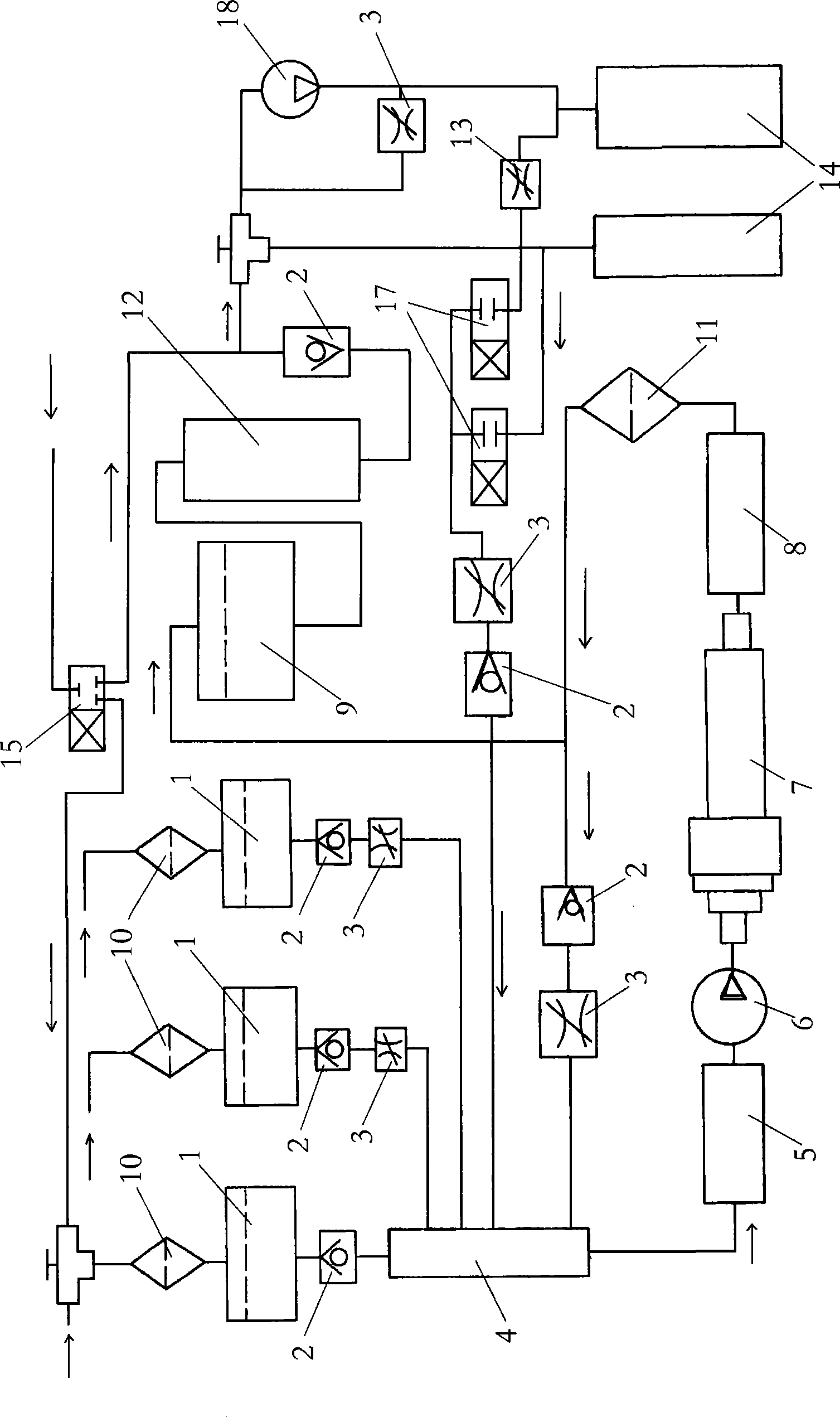

[0022] See Figure 1 ~ Figure 2 , specific embodiments of the present invention are as follows: each fuel to be mixed and emulsified enters a respective constant pressure container, and the fuel has petrochemical fuel (such as gasoline or diesel oil), or alcohol or vegetable oil, and the petrochemical fuel is passed through an electromagnetic reversing valve. 15 into a filter 10, constant pressure oil tank 1 and check valve 2 into the pre-mixer 4, while alcohol or vegetable oil enters through other filters 10, constant pressure oil tank 1, check valve 2 and throttle valve 3 Pre-mixer 4, throttling valve 3 can control alcohol or vegetable oil to enter pre-mixer 4 according to the proportion selected appropriately, after two kinds of fuels such as diesel oil and alcohol or diesel oil and vegetable oil or diesel oil and water enter pre-mixer 4, Carry out premixing, premixing is a kind of mechanical mixing, and described premixer 4 is a cavity, and there is a rotating body in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com