Non-powder water swelling nonwoven fabric and production method thereof

A water-swelling, non-woven fabric technology, applied in the direction of non-woven fabrics, textiles, papermaking, fiber treatment, etc., can solve the problems of non-woven fabrics such as reduced strength, affecting performance, easy to fall off, etc., and achieves good water blocking effect and is practical Strong performance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

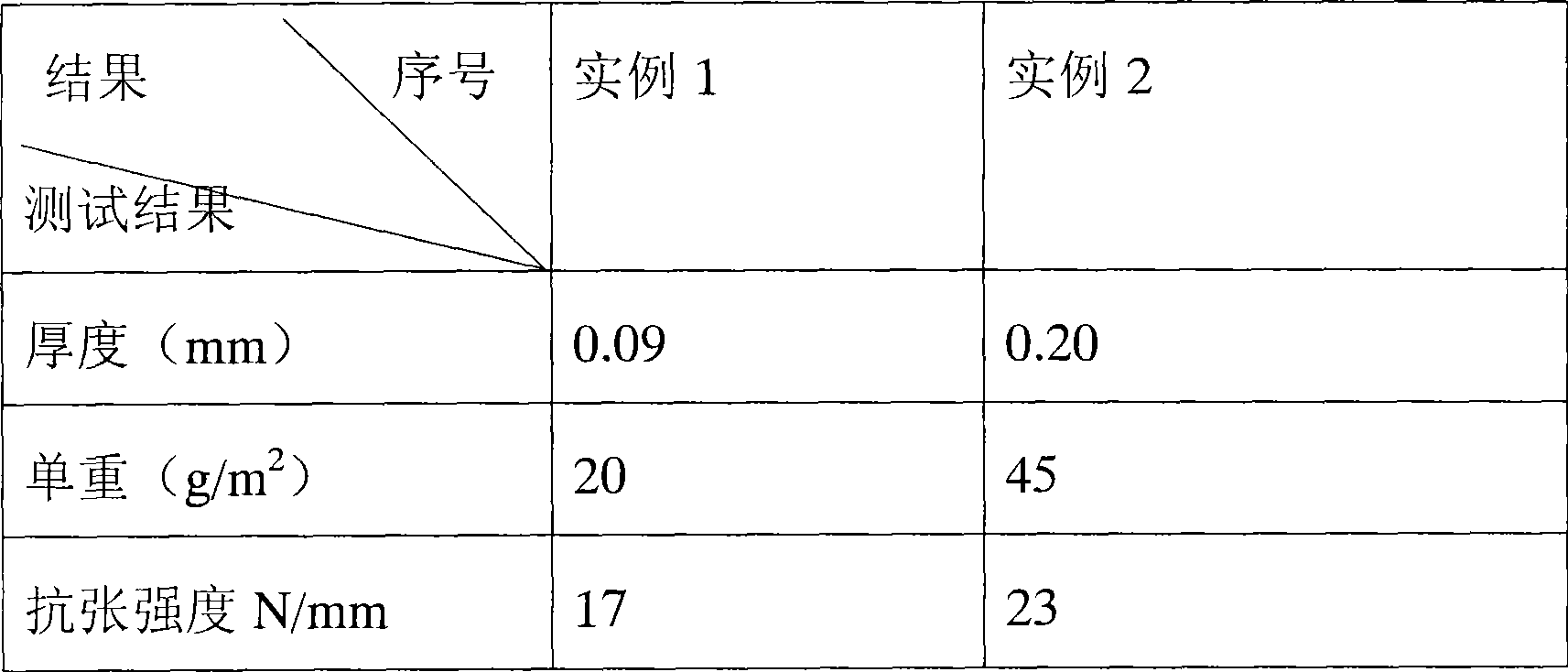

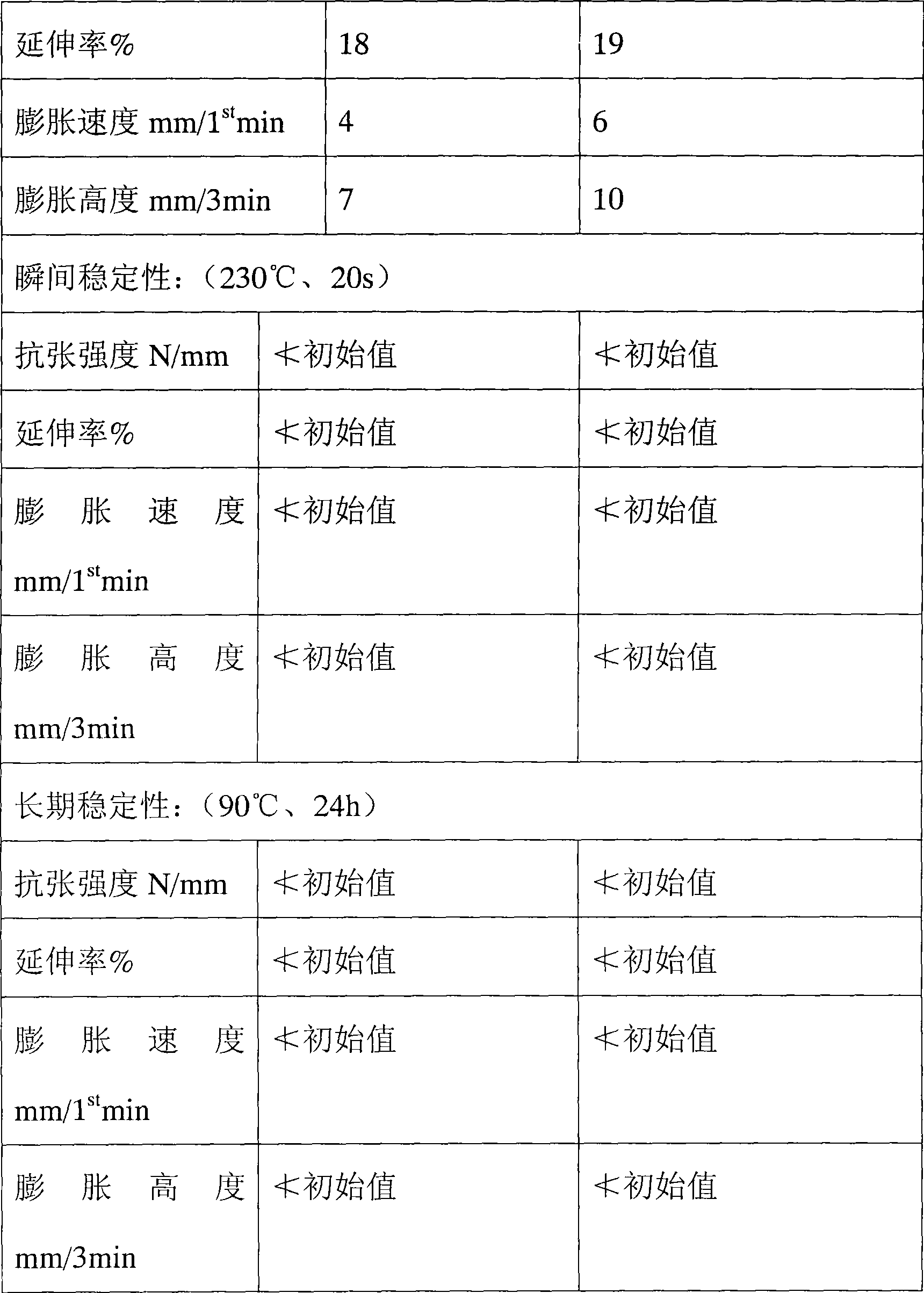

Embodiment 1

[0034] (1) 1.56D×51mm polyester staple fiber;

[0035] (2) Glue formula:

[0036] 50 parts of water

[0037] Acrylic 30 parts

[0038] Alkali 20 parts

[0039] Acrylamide 30 parts

[0040] Initiator 0.5 parts

[0041] Cross-linking agent 0.05 part

[0042] Thickener 6 parts

[0043] 1 part of cross-linking auxiliary agent;

[0044] (3) The drying temperature is 150°C, and the walking speed is 8 m / min;

[0045] (4) cutting the product obtained in step 3;

[0046] (5) Packaging the product obtained in step 4 is the finished product.

Embodiment 2

[0048] (1) 1.56D×38mm polyester staple fiber;

[0049] (2) Glue formula:

[0050] 30 parts of water

[0051] Acrylic 50 parts

[0052] 30 parts of alkali

[0053] Acrylamide 40 parts

[0054] Initiator 0.5 parts

[0055] Cross-linking agent 0.1 part

[0056] Thickener 8 parts

[0057] 2 parts of cross-linking auxiliary agent;

[0058] (3) The drying temperature is 180°C, and the walking speed is 10 m / min;

[0059] (4) cutting the product obtained in step 3;

[0060] (5) Packaging the product obtained in step 4 is the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com