Double salient motor system for non-position sensor and control method thereof

A doubly salient motor and control circuit technology, applied in the direction of single motor speed/torque control, electronic commutator, etc., to simplify the structure of the analog system, reduce costs, and save research funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

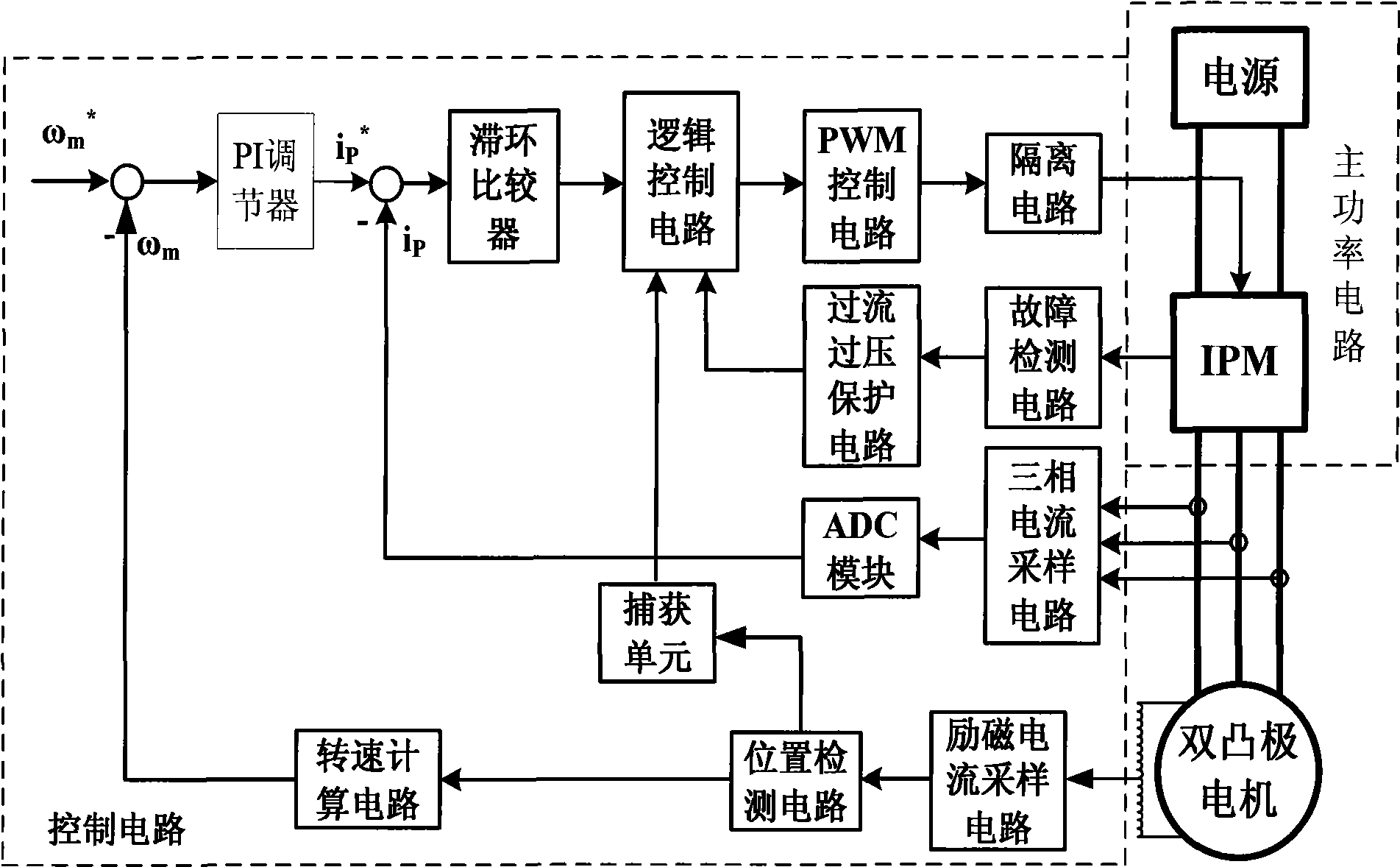

[0012] Such as figure 1 shown. A sensorless doubly salient motor system consisting of a doubly salient motor, an excitation winding, a main power circuit and a control circuit, wherein the main power circuit includes a power supply and an IPM, and the two output ends of the power supply are respectively connected to the two inputs of the IPM The three output terminals of the IPM are respectively connected to the three input terminals of the doubly salient pole motor, and the output terminals of the doubly salient pole motor are connected to the input terminals of the excitation winding. The control circuit includes an isolation circuit, a fault detection circuit, three Phase current sampling circuit, excitation current sampling circuit, PWM control circuit, overcurrent and overvoltage protection circuit, ADC module, position detection circuit, speed calculation circuit, logic control circuit, capture unit, speed loop, current loop, hysteresis comparator and PI regulator, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com