Process for production of hard butter suitable for chocolate product

A lipase and long-chain fatty acid technology, applied in the field of hard fat preparation, can solve the problems of large amount of immobilized lipase, complicated production steps, long reaction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0067] Preparation Example 1 [Preparation of Powdered Lipase Composition]

[0068] 5 g of Lipozyme TL-IM (Novozymes A / S) was pulverized with an L-type micronizer (Tokushu kika kogyo Co., Ltd). The pulverized lipases were measured with a particle size distribution analyzer LA-500 (HORIBA, Ltd), and their average particle size was 66.4 μm. 5 g of cellulose powder (NIPPON PAPER CHEMICALS Co., Ltd: average particle diameter 30 μm) was added to the powdered lipase to obtain a powder composition. 90 g of rapeseed oil and 10 g of ODO (Nisshin OilliO Group, Ltd) were added to 5 g of the powder composition, and the resultant was stirred at 25° C. for 5 hours and then filtered. As a result, a powdered lipase composition was obtained.

preparation Embodiment 2

[0069] Preparation Example 2 [Preparation of Powdered Lipase Composition 2]

[0070] A 10% aqueous solution of deodorized whole-fat soybean flour, which is available under the trade name "Alphaplus HS-600" manufactured by Nisshin CosmoFoods Ltd., was previously autoclaved at 121° C. for 15 minutes and cooled to about room temperature. and have a fat content of 23% by mass. Three times the amount of cooling liquid was added to the enzyme solution of lipase DF "Amano" 15-K manufactured by Amano Enzyme Inc., also known as lipase D (150000 U / ml). The resulting solution was adjusted to pH 7.8 with a 0.5N NaOH solution, and then spray-dried with a spray dryer (SD-1000: Tokyo Rikakikai Co., Ltd). As a result, powdery lipase composition 2 was obtained.

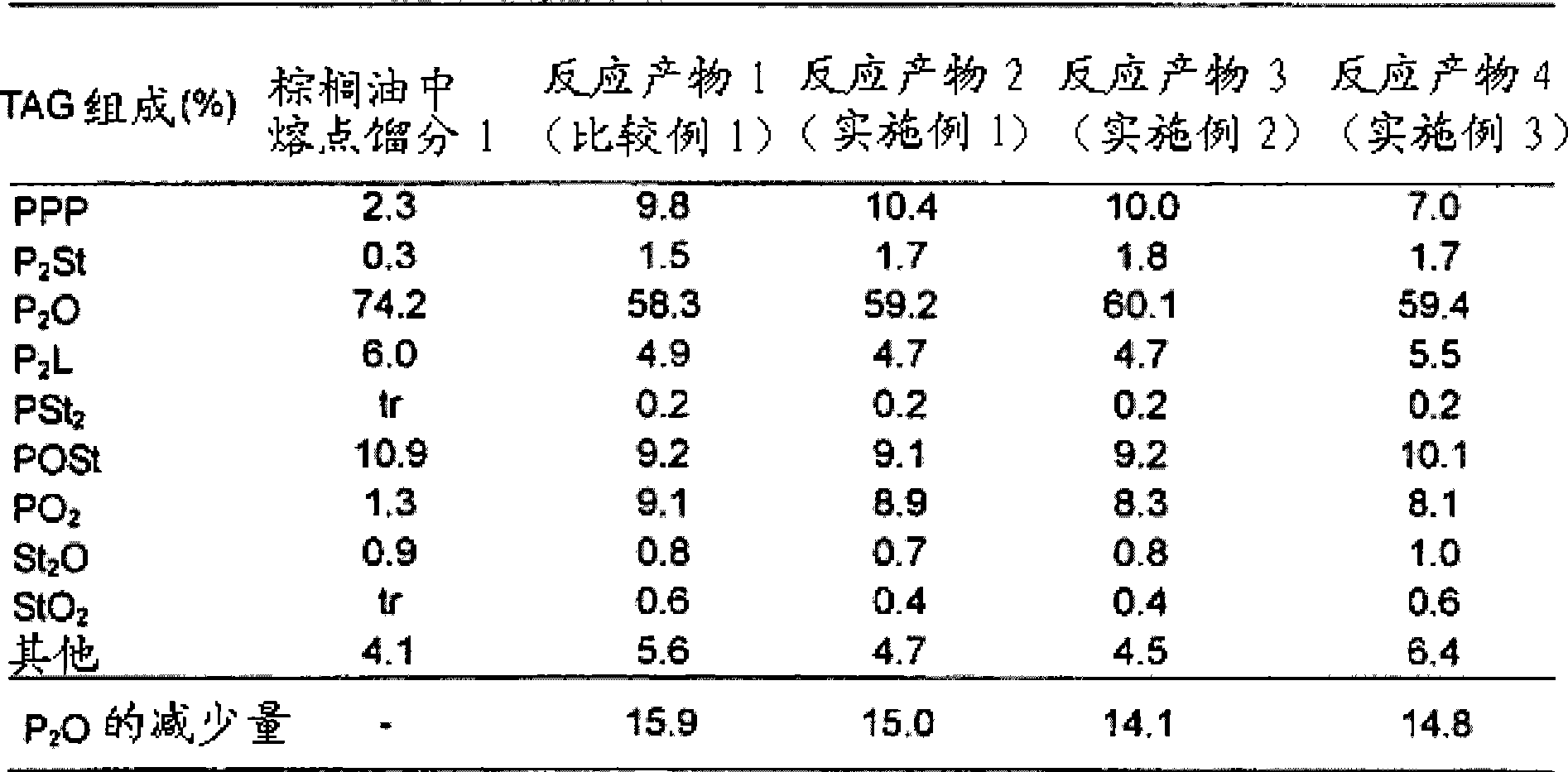

Embodiment 1

[0074] To the same 10 g of palm oil mid-melting fraction 1 (composition: 62.3 mass % of POP, 11.9 mass % of PPO) as used in Comparative Example 1 was added 1.5 mass % of Lipozyme TL-IM manufactured by Novozymes A / S ( Immobilized lipase derived from Thermomyces genus; average particle size 800 μm), then reacted at 70° C. for 4 hours under stirring. The resulting solution was filtered to remove immobilized lipase, as a result of which 9.6 g of reaction product 2 were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com