Positive electrode active material for nonaqueous electrolyte secondary battery and nonaqueous electrolyte secondary battery

A positive electrode active material and non-aqueous electrolyte technology, which is applied in the field of non-aqueous electrolyte secondary batteries, can solve the problems of shortened life of non-aqueous electrolyte secondary batteries and the inability to ensure the conductivity of the positive electrode, and achieve excellent output characteristics and cycle characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

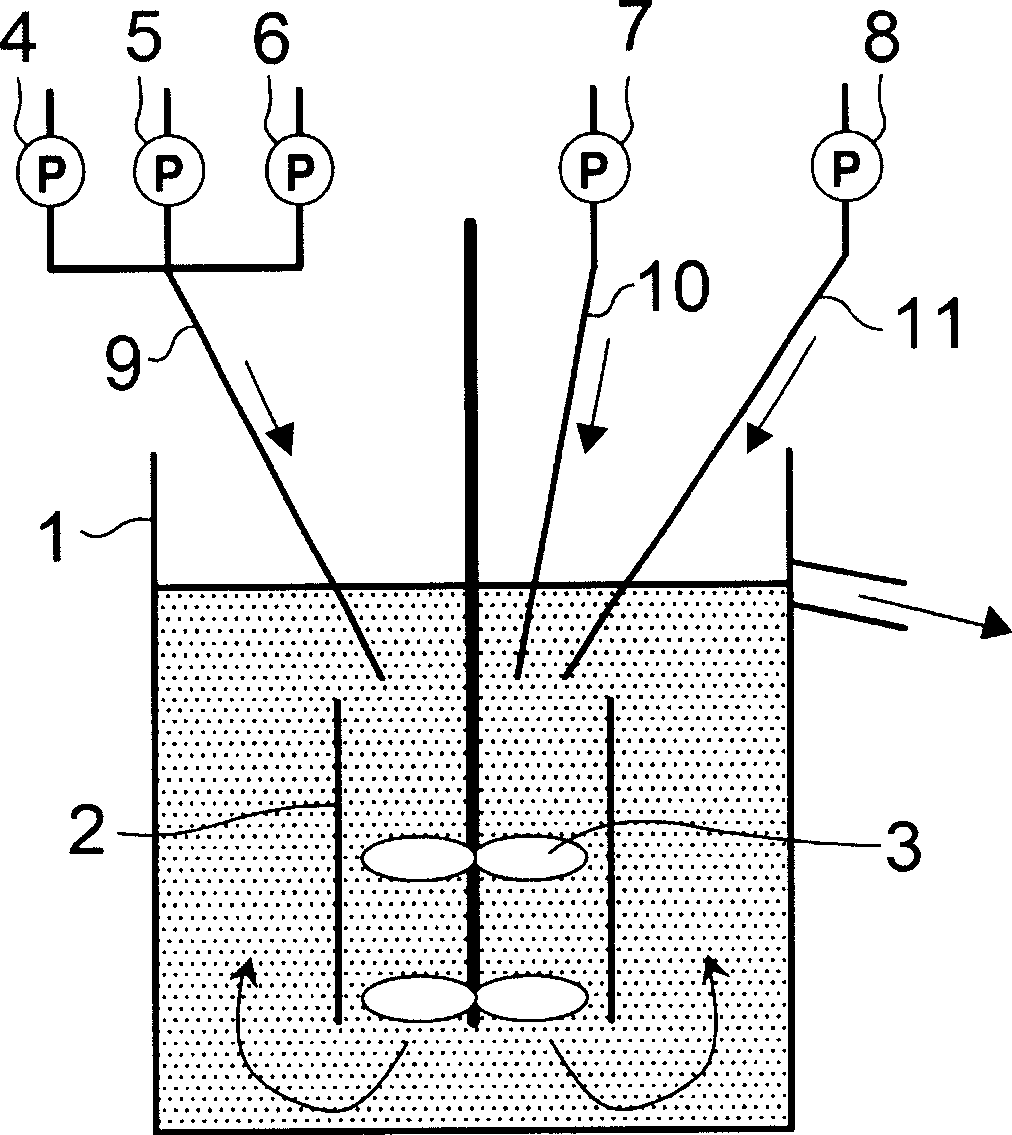

[0063] The schematic diagram of the manufacturing device for synthesizing hydroxide (the raw material of the positive electrode active material) is shown in figure 1 shown. As raw materials, 1 mol / L nickel sulfate aqueous solution, 1 mol / L manganese sulfate aqueous solution, 1 mol / L manganese sulfate aqueous solution, 1 mol / L A cobalt sulfate aqueous solution, a 5 mol / L ammonia solution, and a 5 mol / L sodium hydroxide solution were continuously supplied to the reaction tank 1 while being stirred. In addition, the sulfate aqueous solution of metal elements was supplied from the pumps 4 to 6 , the sodium hydroxide aqueous solution was supplied from the pump 7 , and the ammonia aqueous solution was supplied from the pump 8 .

[0064] Here, the manufacturing apparatus will be described. The manufacturing device is provided with conduits 9-11 for injecting the above-mentioned solution from pumps 4-8 into the reaction tank 1, and the sulfate aqueous solution of the above-mentioned...

Embodiment 2

[0115] use figure 1 The reaction tank 1 of the present invention produces hydroxide (raw material of positive electrode active material) mainly composed of Ni. As raw materials, 1 mol / L nickel sulfate aqueous solution, 1 mol / L cobalt sulfate aqueous solution, 1 mol / L cobalt sulfate aqueous solution, 1 mol / L Aluminum sulfate aqueous solution (depending on the situation, it can also be not 1mol / L aluminum sulfate aqueous solution but 1mol / L manganese sulfate aqueous solution), 5mol / L ammonia solution and 5mol / L sodium hydroxide solution while stirring continuously Supplied to reaction tank 1. Hereinafter, various composite hydroxides having different compositions were produced in the same manner as in Example 1.

[0116] Next, these composite hydroxides were washed with water, dried, and then fired in the air to form composite oxides. In this manner, various composite oxides having different element ratios of Ni, Co, and Al in the composite oxide and sizes of secondary partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com