Method for reducing laser welding pores of cast magnesium alloy

A technology for casting magnesium alloys and laser welding, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problem of limited preventive measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

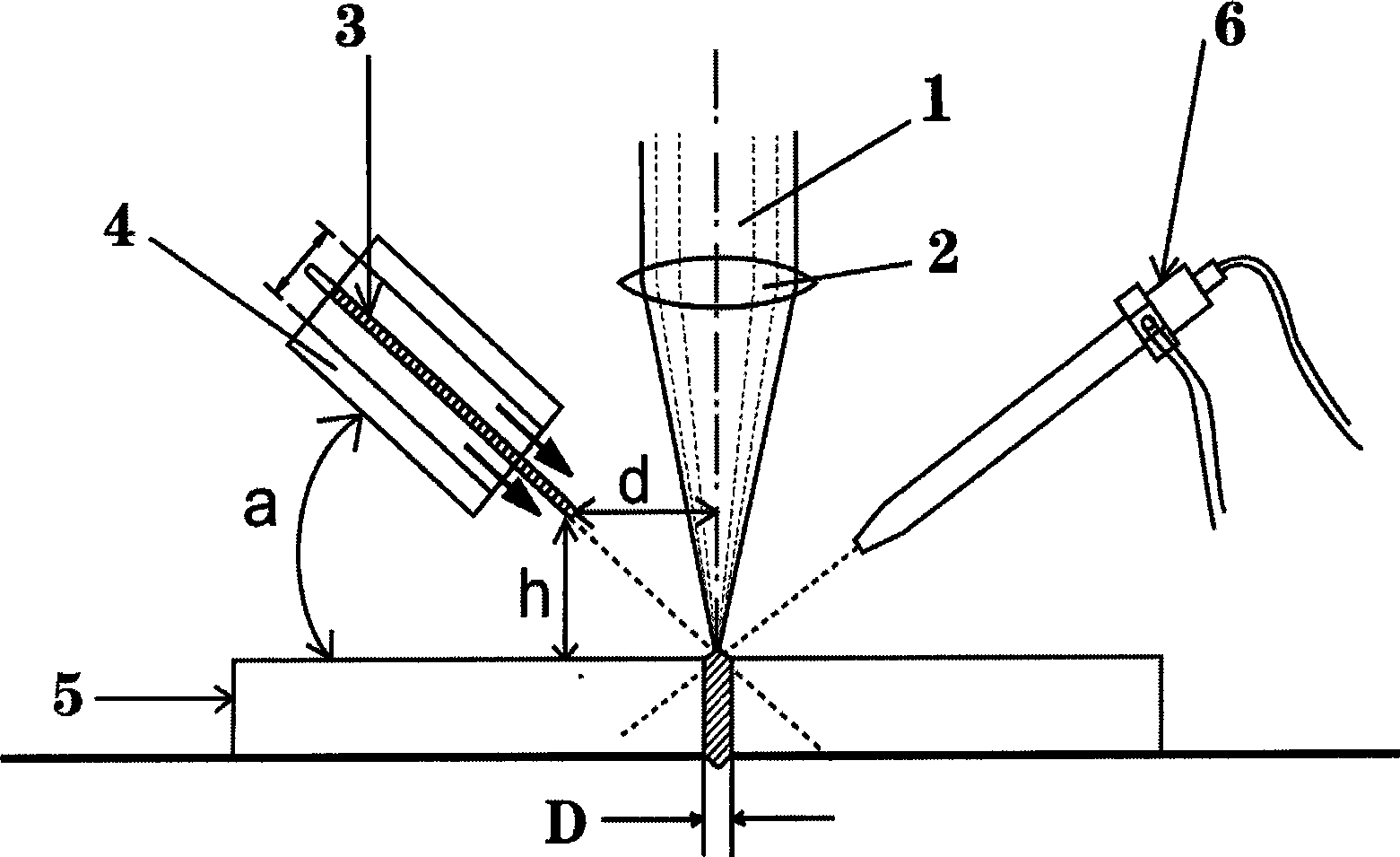

Method used

Image

Examples

Embodiment 1

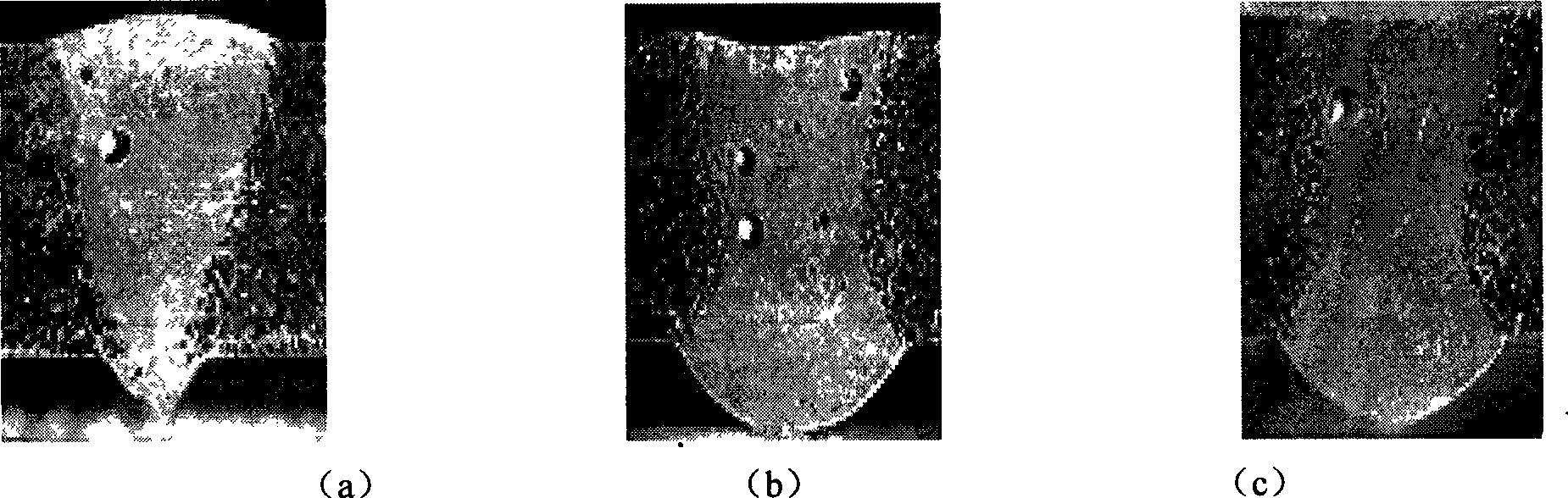

[0019] In the experiment, for cast magnesium alloys with base metal shrinkage porosity of 2% to 5%, the thickness of the plate is 4mm. During self-fluxing welding, the process parameters are optimized. The power is 3500W, the welding speed is 3m / min, and the defocus is In the case of -2, penetration can be achieved, and the obtained weld section is as follows figure 2 shown.

[0020] In the case of adding welding wire, the power is 3500W, the welding speed is 3m / min, the defocus is -2, the wire feeding speed is 1.0m / min, h=0.5mm d=0.5mm a=35° The weld cross-section is as image 3 shown.

Embodiment 2

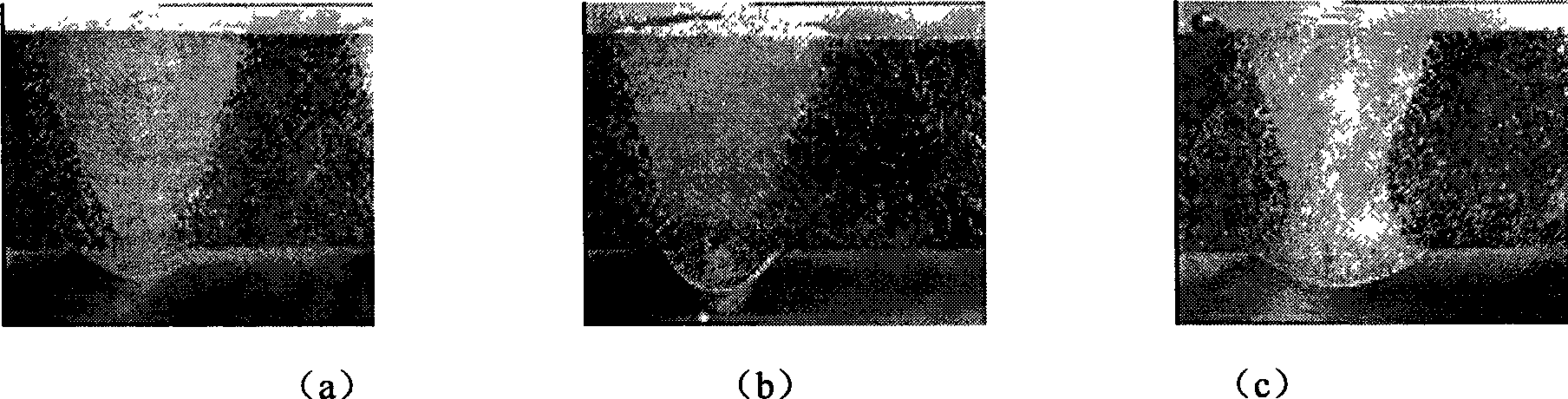

[0022] In the experiment, for the cast magnesium alloy with base metal shrinkage rate of 12-15%, the thickness of the plate is 4mm. During self-fluxing welding, the process parameters are optimized. The power is 3500W, the welding speed is 2m / min, and the defocus amount is - In the case of 2, penetration can be achieved, and the obtained weld cross section is as follows Figure 4 shown.

[0023] In the case of adding welding wire, the power is 3500W, the welding speed is 2m / min, the defocus is -2, the wire feeding speed is 1.8m / min, h=0.5mm d=0.5mm a=35° The weld cross-section is as Figure 5 shown.

[0024] It can be clearly seen from the figure that the effect of filler wire on the porosity control of laser-welded cast magnesium alloys is obvious. For cast magnesium alloys with shrinkage porosity of 2% to 5%, the average porosity of the weld is 5% in the case of self-fluxing welding. The average porosity of the weld after welding wire is 0.5%.

[0025] The average porosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com