Composition for purification treatment of waste phosphogypsum, treating method and construction material obtained thereby

A technology for building materials and compositions, applied in the field of building materials, can solve the problems of occupying land, scattered with the wind, pollution of the surrounding environment, etc., and achieves the effect of solving the problem of purification treatment, avoiding secondary pollution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

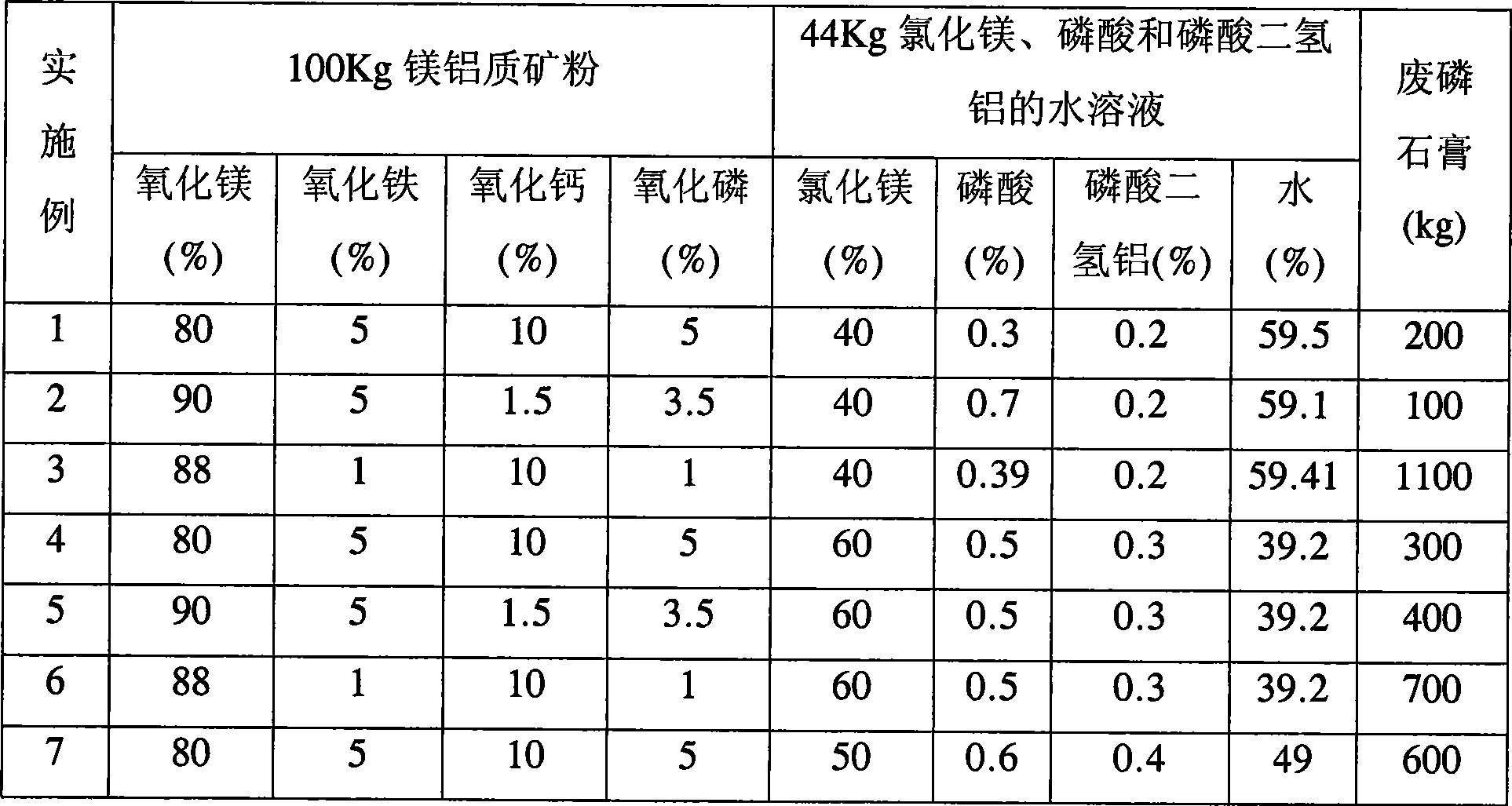

Embodiment 1~10

[0016] Mix according to the raw material formulations in Examples 1-10 in Table 1, stir for 3 minutes and then solidify naturally.

[0017] Table 1

[0018]

[0019]

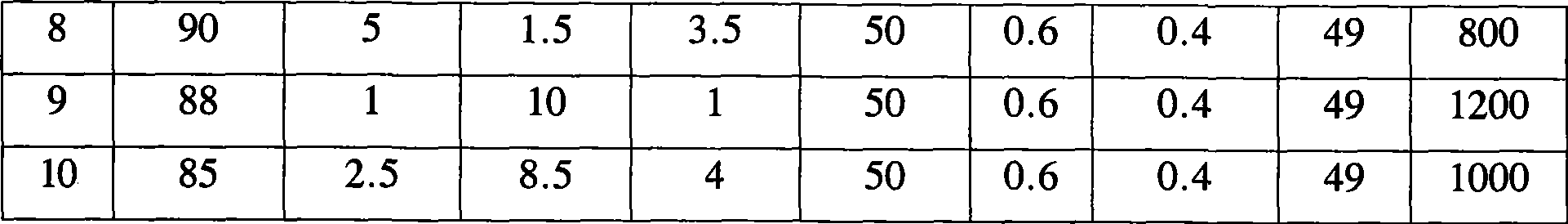

Embodiment 11~20

[0021] Mix according to the raw material formulations in Examples 11-20 in Table 2, stir for 6 minutes, put into a mold with a fixed shape, and naturally solidify after extrusion molding and demoulding.

[0022] Table 2

[0023]

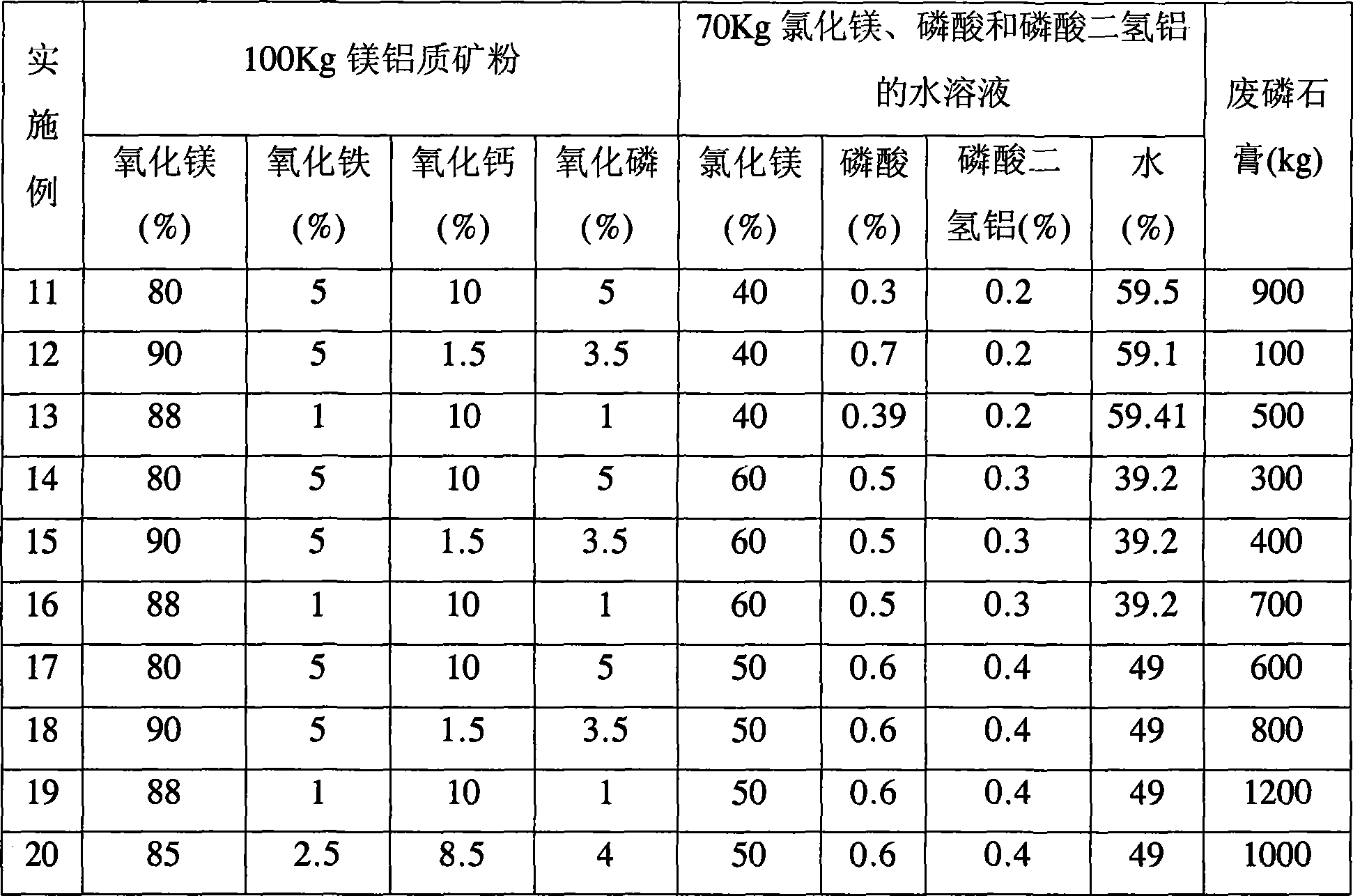

Embodiment 21~30

[0025] Mix according to the raw material formulations in Examples 21-30 in Table 3, stir for 5 minutes, put into a mold with a fixed shape, and naturally solidify after extrusion molding and demoulding.

[0026] table 3

[0027]

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com