Technique for purifying crude terephthalic acid from alkali deweighting wastewater

A technology for crude terephthalic acid and alkali reduction waste water, which is applied in the field of crude terephthalic acid purification process, and can solve the problem that there is no good method for recrystallization of terephthalic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

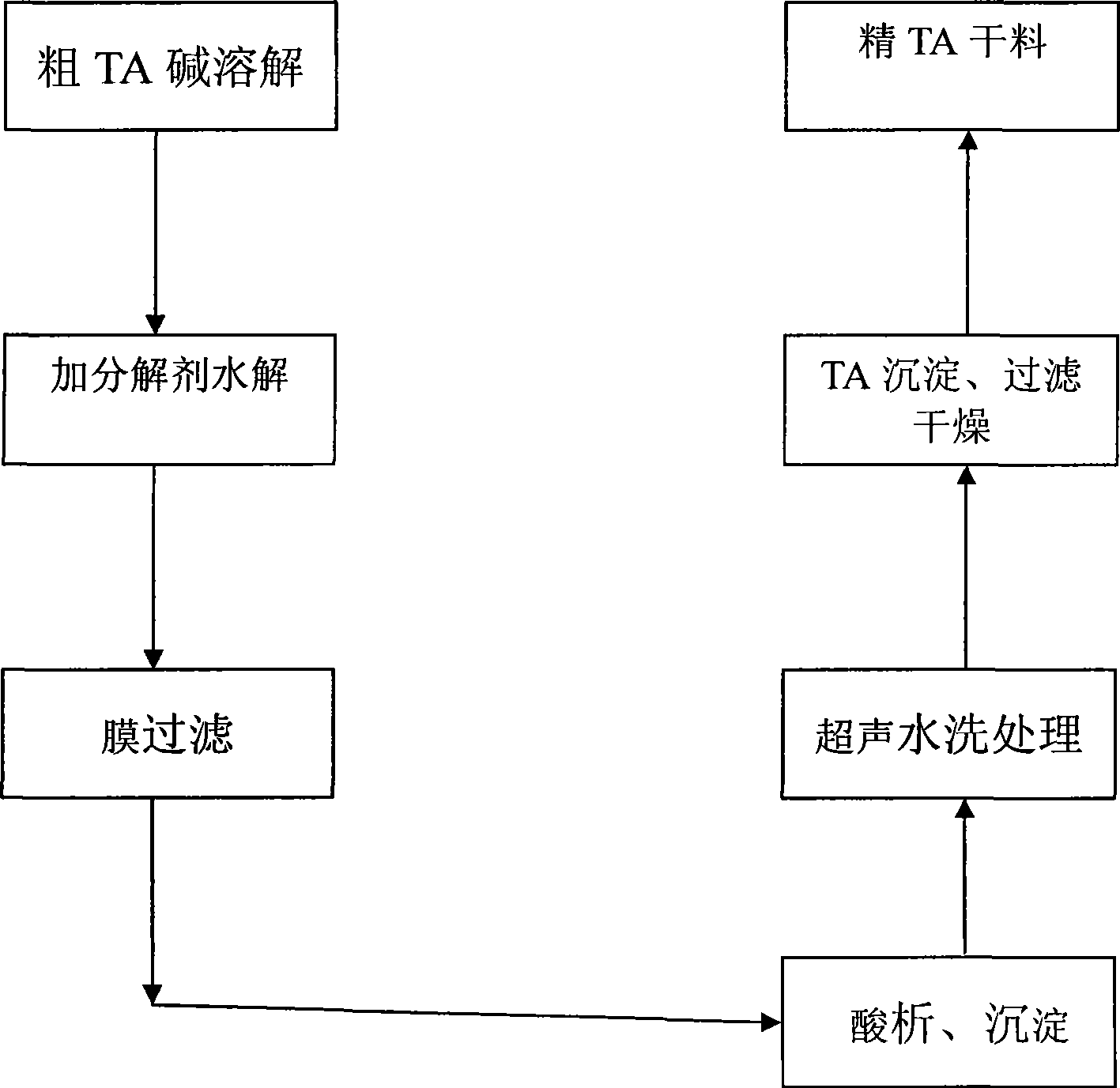

[0038] Crude terephthalic acid purification process for general purity requirements

[0039] The crude terephthalic acid recovered by membrane integrated treatment technology is dissolved in water under the condition of excessive NaOH, and the pH is controlled at 12 to 14. Under the premise of stirring, 1% of the mass of crude terephthalic acid is added in benzene, and then heated , keep the temperature of the crude terephthalic acid alkali solution between 80°C and 120°C, then add 5% hydrogen peroxide (mass percentage concentration of 10%) of the crude terephthalic acid mass, and continue stirring for 3-5 hours for hydrolysis , stop stirring, cool to 30-50°C, then filter the impurities, collect the filtrated liquid, and perform ultrafiltration to remove water-soluble macromolecular impurities.

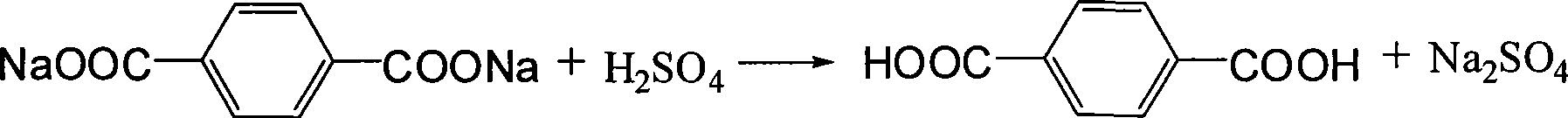

[0040] Add dilute sulfuric acid solution for neutralization, so that the terephthalic acid in the solution is slowly acid-precipitated from the liquid phase, and the pH value is contr...

Embodiment 2

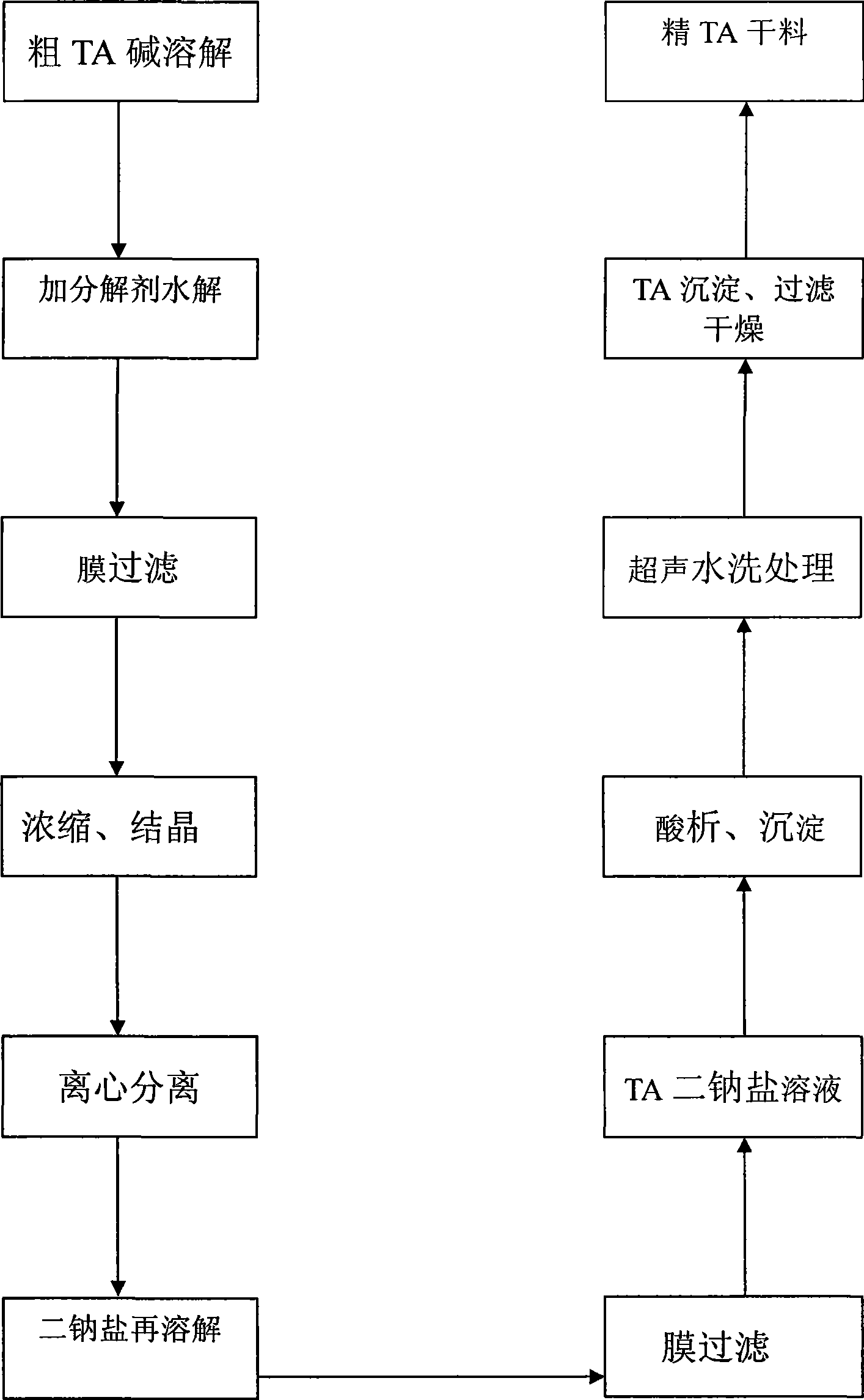

[0042] Refining Process of High Purity Terephthalic Acid

[0043] The crude terephthalic acid recovered by membrane integrated treatment technology is dissolved in water under the condition of excessive NaOH, and the pH is controlled at 12 to 14. Under the premise of stirring, 0.5-1.5% of the mass of crude terephthalic acid is added with N- Sodium oleoyl polypeptide, then heated to keep the temperature of the crude terephthalic acid alkali solution between 80°C and 120°C, then add 5% hydrogen peroxide (mass percentage concentration is 10% ), continue to stir and hydrolyze for 3-5 hours, stop stirring, cool to 30-50°C, then filter the impurities, collect the filtered clear liquid, and the filtered clear liquid can be filtered by ultrafiltration or nanofiltration according to requirements to further remove the dissolved Oligomer molecules, oligomer decomposers, etc. in serum.

[0044] Remove the clear liquid of oligomer molecules through membrane filtration. If the concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com