Organic gas sensing method

A technology of organic gas and sensing method, which is applied in the fields of environmental monitoring and optical sensors, can solve the problems of inability to meet the needs of gas sensing and low sensitivity, and achieve the effect of low cost and convenient realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1, using the sensing method of the present invention to complete the detection of butanol gas.

[0030] (1) Select K9 glass with a size of 10mm×20mm×2mm as the sensor chip substrate, and clean and dry the substrate;

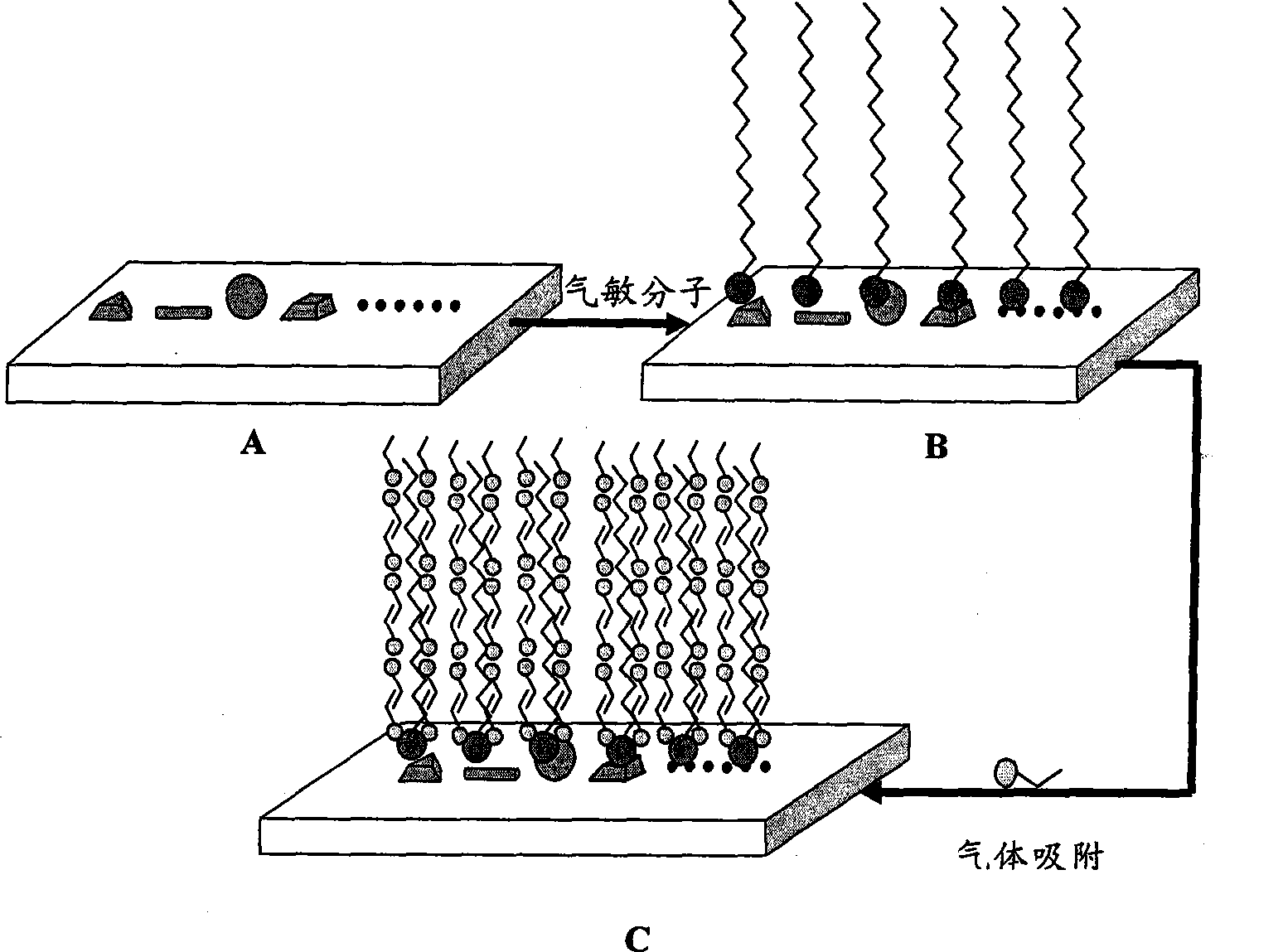

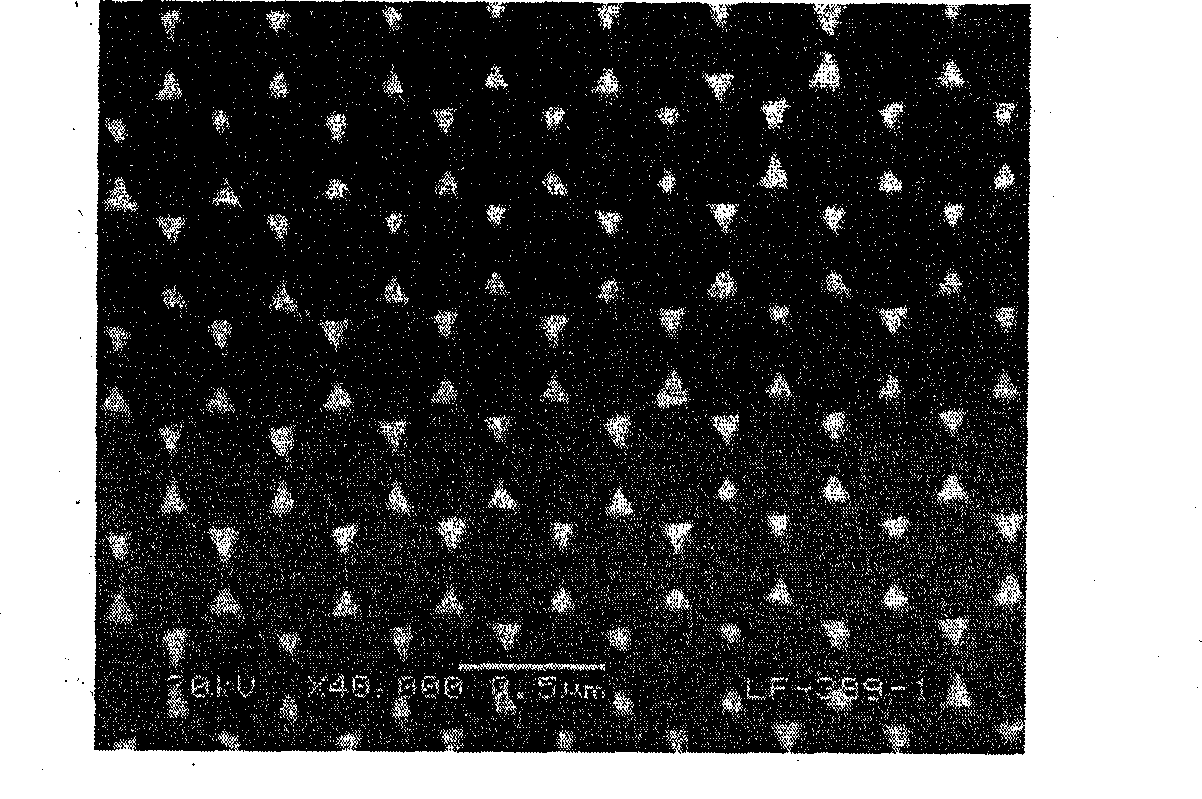

[0031] (2) Utilize nanosphere photolithography to make a layer of triangular silver nanoarrays on the above-mentioned selected glass substrate, such as figure 1 The first structure in (A), the triangle side length is 127nm, the period is 400nm, figure 2 is the corresponding SEM photo;

[0032] (3) The sensor chip containing the triangular silver nanostructure obtained by step (2) is immersed in a concentration of 2.5 × 10 -4 M in mycophenolic acid (MPA) solution (solvent is ethanol) for three minutes to form a layer of molecular film sensitive to butanol gas, such as figure 1 (B);

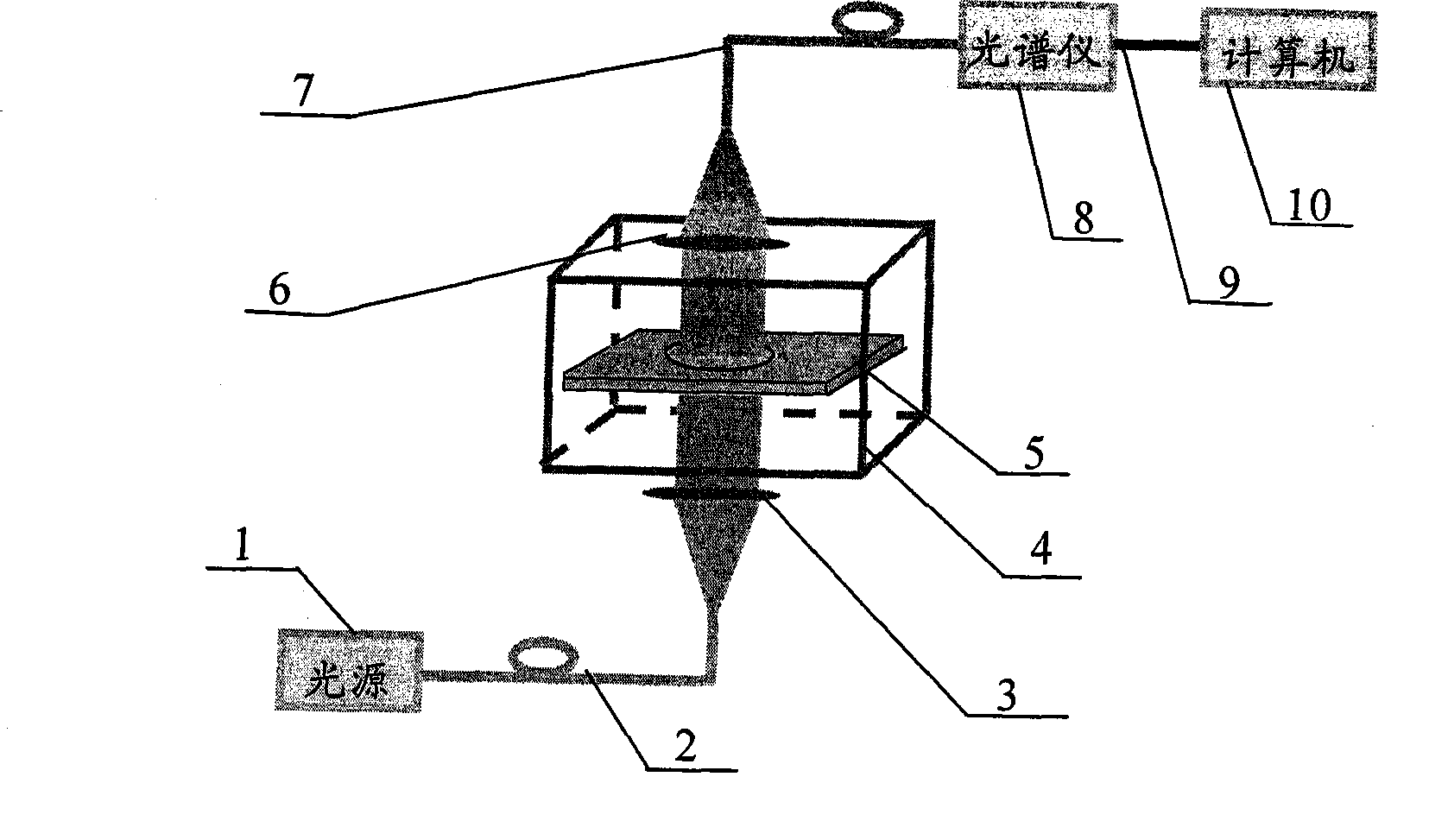

[0033] (4) Step (3) gained structure is placed in the air that contains butanol molecule, and the molecular film of structure top layer absorbs the butanol molecul...

Embodiment 2

[0037] Embodiment 2, using the sensing method of the present invention to complete the detection of p-xylene gas.

[0038] (1) Select K9 glass with a size of 10mm×20mm×2mm as the sensor chip substrate, and clean and dry the substrate;

[0039] (2) Utilize electron beam lithography to make diamond-shaped gold nanostructures on the above-mentioned selected substrate, such as figure 1 In the fourth structure in (A), the length of the bottom side is 120nm, the angle between the two sides is 60°, the vertical height is 50nm, and the period is 400nm;

[0040] (3) The diamond-shaped gold nanostructure obtained by step (2) is immersed in a concentration of 5 × 10 -4 M in the thiophenol (BT) solution (solvent is ethanol) for three minutes, form a layer of p-xylene gas comparatively sensitive molecular film, as figure 1 (B);

[0041] (4) the structure obtained in step (3) is placed in the air containing xylene, and the molecular film on the surface layer of the structure absorbs xyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Feature size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com