Large flue gas desulfurization dust-removal system

A technology for desulfurization, dust removal, and flue gas, which is applied in the direction of magnesium sulfate, sulfur compounds, and climate sustainability, and can solve problems such as underutilization of heat energy, low operational reliability, and reduced dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

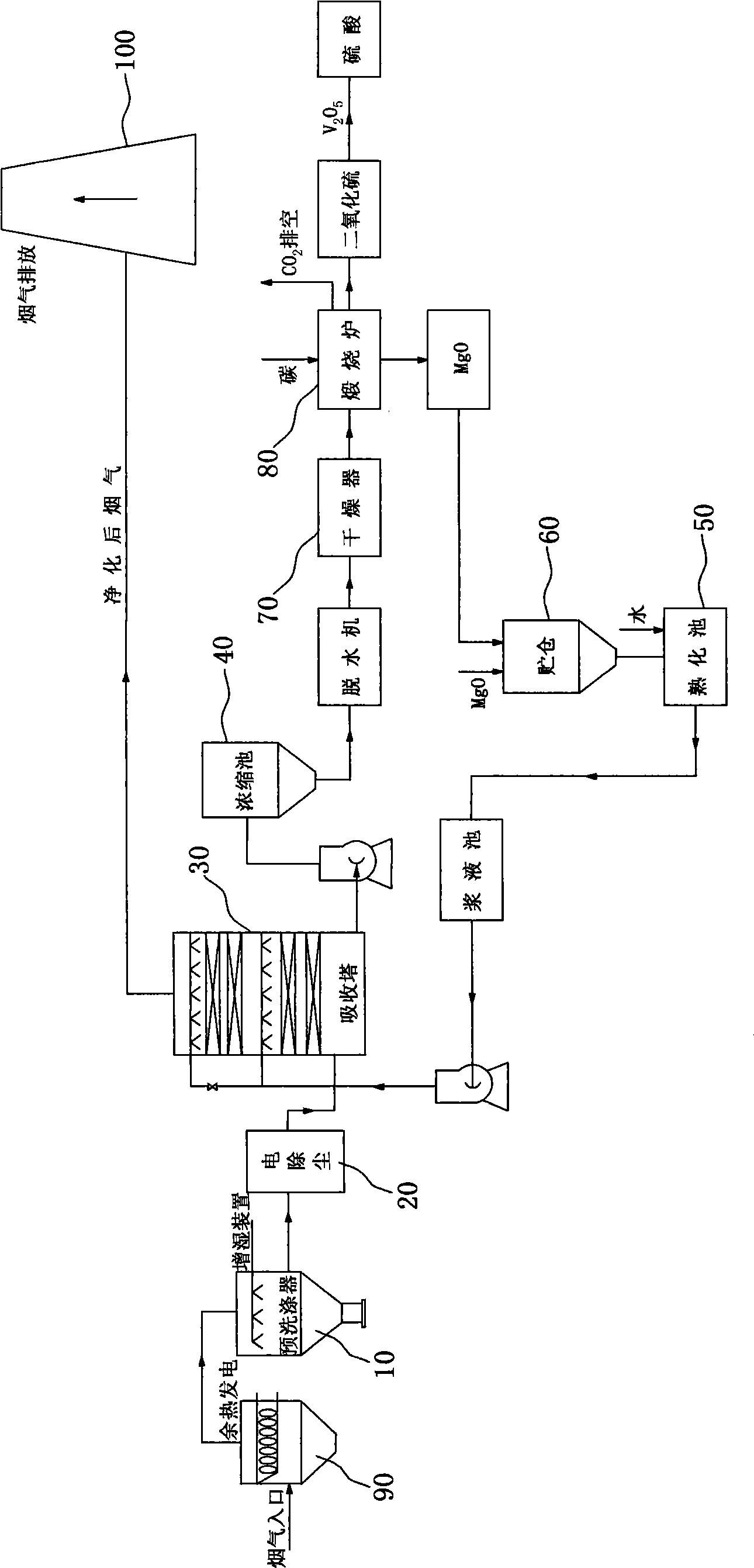

[0015] combine figure 1 , first carry out the pre-dust removal process: in order to prevent the fly ash in the flue gas from entering the absorption tower and depositing it into the desulfurization cycle system, so a pre-dust removal device, namely a pre-scrubber 10, is installed in front of the absorption tower 30. The pre-dust removal device can use Venturi washing to pre-treat the flue gas, so that the temperature of the flue gas is lowered, the temperature is increased, and the fly ash is removed, which is beneficial to the subsequent absorption reaction.

[0016] SO 2 Absorption: In the absorption tower, the flue gas is in contact with the circulating slurry, SO 2 Reacts with absorbents to be removed from flue gas.

[0017] Concentration and drying of the slurry: the content of the slurry discharged from the absorption tower is about 10%, firstly through concentration to increase the solid content of the slurry, and then dehydration and drying. Remove solid surface wat...

Embodiment 2

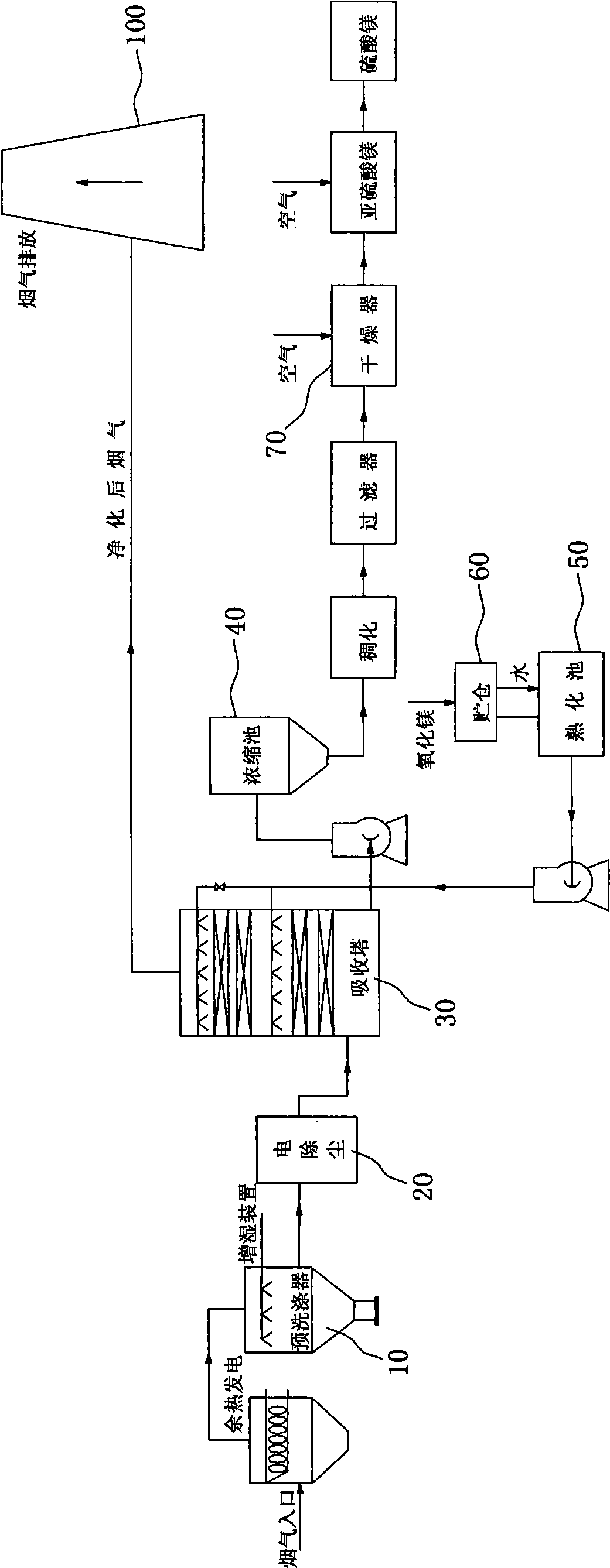

[0022] combine figure 2 , the slurry in the concentration pool 40 is thickened and filtered, and a filter press is used to filter during the dehydration process. Thickening and filtration are all carried out in the concentration pool 40, and the MgSO 3 Fully oxidized with oxygen in the air to obtain commercial magnesium sulfate. Magnesium sulfate can be used as a softener in the paper industry and a compound magnesium fertilizer in the fertilizer industry to improve the yield and quality of crops.

Embodiment 3

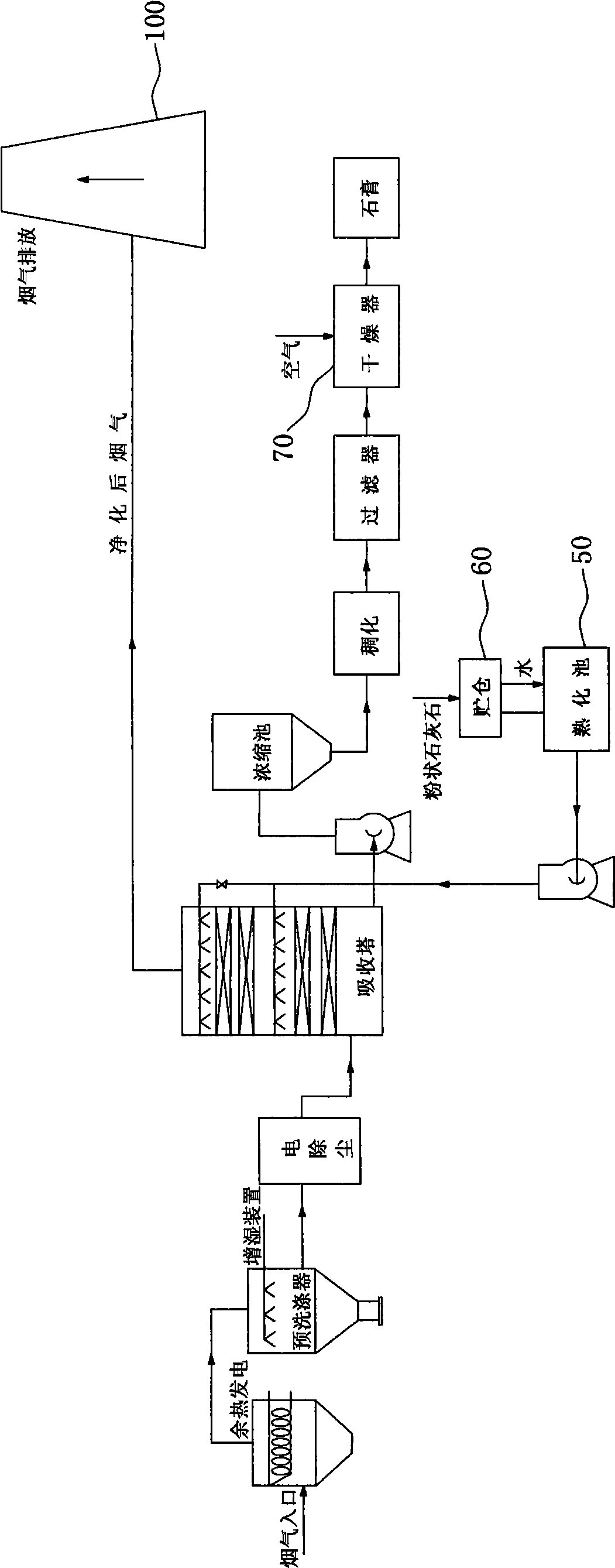

[0024] combine image 3 , put powdery limestone in the storage bin 60 and the aging tank 50, transport it to the absorption tower 30 to absorb the pharynx gas, process the pharynx gas through the concentration tank 40, filter it through a filter after thickening, and then dry it in the drier 70 , get gypsum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com