Polyacrylonitrile ultrafiltration membrane surface hydrolysis method

A polyacrylonitrile, ultrafiltration membrane technology, applied in the field of membrane separation, to achieve the effect of improving anti-pollution and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) The dry / wet phase inversion method is used to prepare a flat polyacrylonitrile ultrafiltration membrane with a molecular weight cut-off of about 100,000 Daltons;

[0020] 2) soak the flat polyacrylonitrile ultrafiltration membrane in ethanol / water solution with ethanol mass content of 25wt%, 50wt%, 75wt% and 100wt% respectively for 120 minutes step by step, so that the water in the membrane pores is completely replaced by ethanol;

[0021] 3) Take the membrane out of absolute ethanol, soak it step by step in cyclohexane / ethanol solutions with cyclohexane mass content of 25wt%, 50wt%, 75wt% and 100wt% for 120 minutes, so that the ethanol in the membrane pores is completely replaced by cyclohexane;

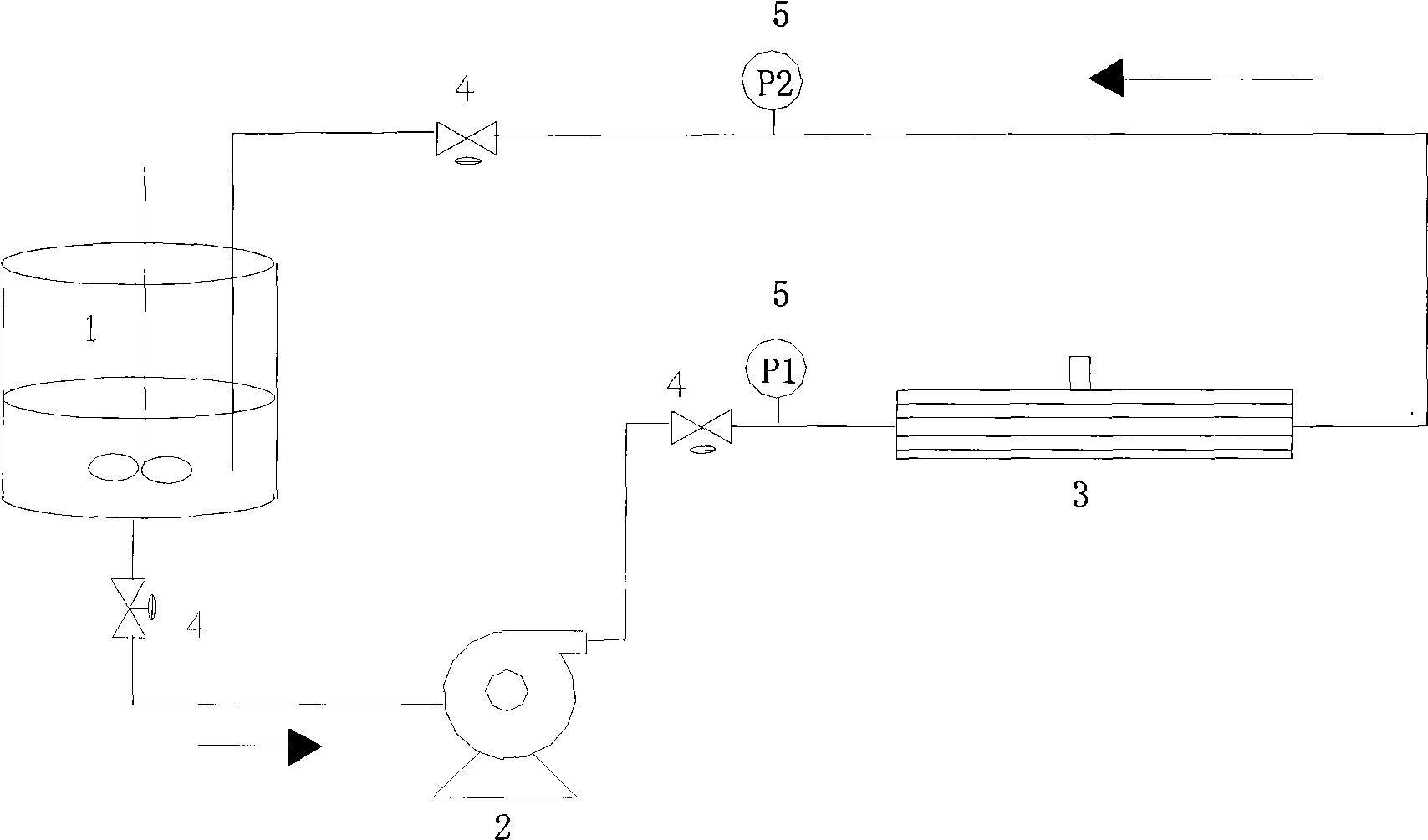

[0022] 4) Take the membrane out of the cyclohexane, place it in a flat-plate polyacrylonitrile ultrafiltration membrane surface hydrolysis device, inject a NaOH solution with a temperature of 60 ° C and a concentration of 2 mol / l into the hydrolysis device, and make one si...

Embodiment 2

[0029] 1) Prepare a flat polyacrylonitrile ultrafiltration membrane by dry / wet phase inversion method, with a molecular weight cut-off of about 10,000 Daltons;

[0030] 2) soak the flat polyacrylonitrile ultrafiltration membrane in ethanol / water solution with ethanol mass content of 25wt%, 50wt%, 75wt% and 100wt% respectively for 120 minutes step by step, so that the water in the membrane pores is completely replaced by ethanol;

[0031] 3) Take the membrane out of absolute ethanol, soak it step by step in cyclohexane / ethanol solutions with cyclohexane mass content of 25wt%, 50wt%, 75wt% and 100wt% for 120 minutes, so that the ethanol in the membrane pores is completely replaced by cyclohexane;

[0032] 4) Take the membrane out of the cyclohexane, place it in a flat-plate polyacrylonitrile ultrafiltration membrane surface hydrolysis device, inject a NaOH solution with a temperature of 80 ° C and a concentration of 1 mol / l into the hydrolysis device, and make one side of the me...

Embodiment 3

[0039] 1) The polyacrylonitrile hollow fiber ultrafiltration membrane is spun by the dry / wet phase inversion method, with an inner diameter of 1.1 mm and a molecular weight cut-off of about 60,000 Daltons. The hollow fiber membrane is placed in a PVC pipe, and both ends are sealed with epoxy resin. End, made of hollow fiber membrane module;

[0040] 2) soak the hollow fiber polyacrylonitrile ultrafiltration membrane module in ethanol / water solution with ethanol mass content of 25wt%, 50wt%, 75wt% and 100wt% respectively for 60 minutes, so that the water in the membrane pores is completely replaced by ethanol ;

[0041]2) Take the membrane assembly out of absolute ethanol, soak it step by step in cyclohexane / ethanol solutions with a mass content of 25wt%, 50wt%, 75wt% and 100wt% of cyclohexane for 60 minutes, so that the ethanol in the membrane pores completely replaced by cyclohexane;

[0042] 3) The membrane assembly is taken out from the cyclohexane and placed in figure 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mwco | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Mwco | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com