Rhizopus and uses thereof

A technology of Rhizopus and application method, applied in the field of industrial microorganisms, can solve the problems of insufficient optical purity of products, difficult product quality control, serious environmental pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

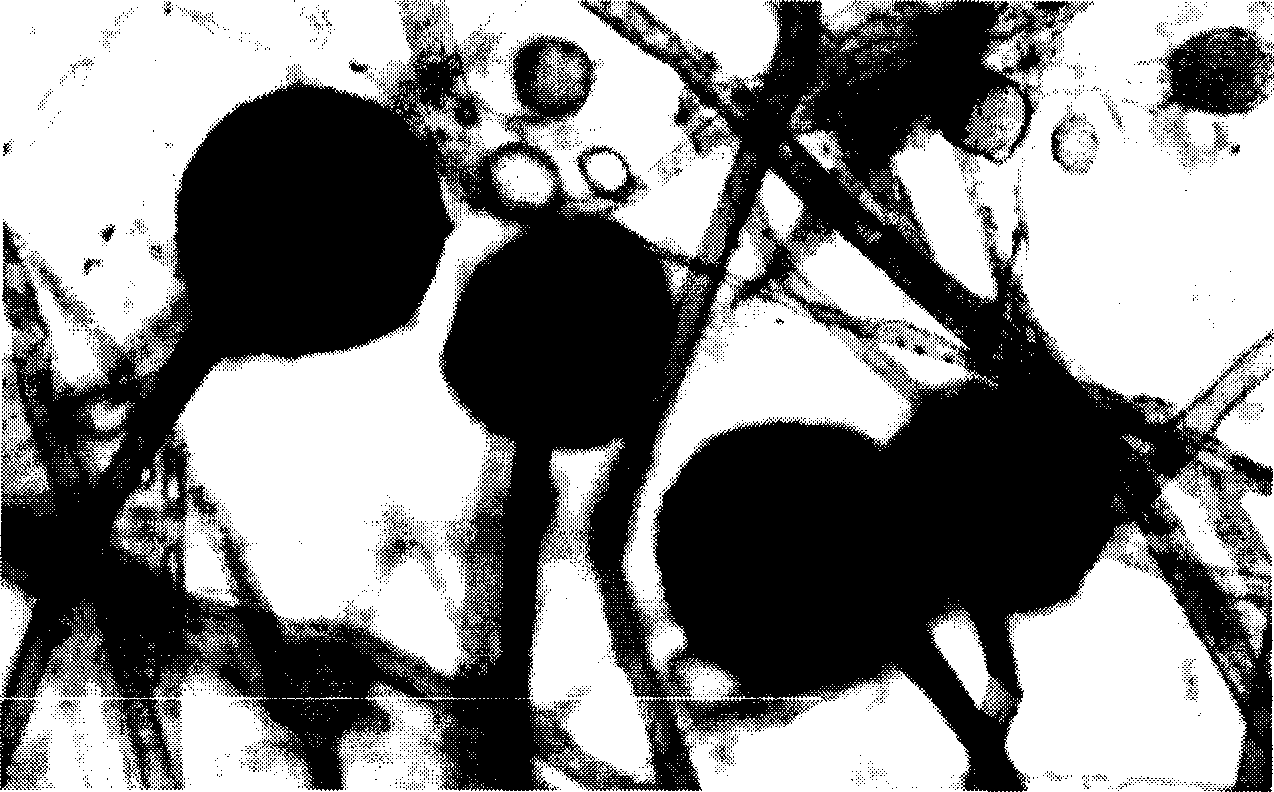

Image

Examples

Embodiment 1

[0027] This embodiment illustrates the screening purification method of Rhizopus Rhizopus sp.B1219:

[0028] PDA solid plate medium formula: 1.0L potato extract, 20.0g glucose, 20.0g agar, 1L distilled water, natural pH.

[0029] PDA liquid medium formula: 1.0L of potato extract, 20.0g of glucose, 1L of distilled water, natural pH.

[0030] 1. Breeding of starting strains:

[0031] Accurately weigh 25g of the wine medicine (taken from Changshu Wangsi Restaurant Yellow Wine Factory) for the production of rice wine, add the wine medicine into a triangular flask filled with 225mL of sterile water under aseptic conditions, shake for 30min, and absorb 1mL of the wine medicine dilution For further gradient dilution, draw 1mL of diluents of distilled spirits of different gradients and place them on the solidified sterile PDA plate medium, and spread the diluents of each gradient concentration evenly on the entire surface of the plate with a sterile applicator stick, 28 Incubate at ...

Embodiment 2

[0038] This example illustrates the application of Rhizopus sp.B1219 in the fermentative production of phenyllactic acid.

[0039] 1. Preparation of Rhizopus sp.B1219 mycelium

[0040] The above-mentioned Rhizopus spores were inoculated in 300mL PDA liquid medium, cultured in a shake flask at 28°C at 200r / min for 72 hours, centrifuged at 3000r / min, and separated from the bacterial liquid to obtain mycelium.

[0041] The formula of the PDA liquid medium is: 1.0L of potato juice, 20g of glucose, and natural pH.

[0042] 2. Fermentation of Rhizopus sp.B1219 mycelium to produce phenyllactic acid

[0043] The mycelium was inserted into 100mL (containing 39% phenylpyruvate) substrate conversion solution according to the inoculum size of 20g, reacted at 35°C for 12h, then extracted with 2 times the volume of ethyl acetate, evaporated and concentrated under reduced pressure to obtain The crude product of phenyl lactic acid, the content of phenyl lactic acid in the conversion solutio...

Embodiment 3

[0049] This example illustrates the application of Rhizopus sp.B1219 in the fermentative production of phenyl lactic acid, and the operation method is the same as the small-scale operation in Example 2. This example is the pilot-scale scale-up of Example 2.

[0050] By the method for embodiment 2, utilize 5L fermentors (with aseptic physiological saline the slant spores are washed down, adjust spore concentration to 10 7 Individuals / mL, inoculated into 3L culture medium, inoculum size 10%, shaking culture at 28°C for 120h) to cultivate mycelia, and transform in a 5L reaction tank (600g of mycelium was inserted into 3L substrate transformation solution) Reaction, the pH value is automatically adjusted with inorganic acid and alkali, and the separation and extraction of the product are carried out according to the method of Example 2. The result is: 35 ℃, conversion reaction time 14 hours, phenyl lactic acid output is 0.55g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com