Turbine shaft engine

A turboshaft engine and generator technology, applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc., can solve the problems of high energy consumption, poor acceleration performance, etc., to solve the problems of poor acceleration and low speed fuel consumption, comfortable maintenance, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0030] Before explaining the present invention, the existing turboshaft engine is briefly introduced, and its inability to be applied to vehicles such as automobiles and trains is analyzed.

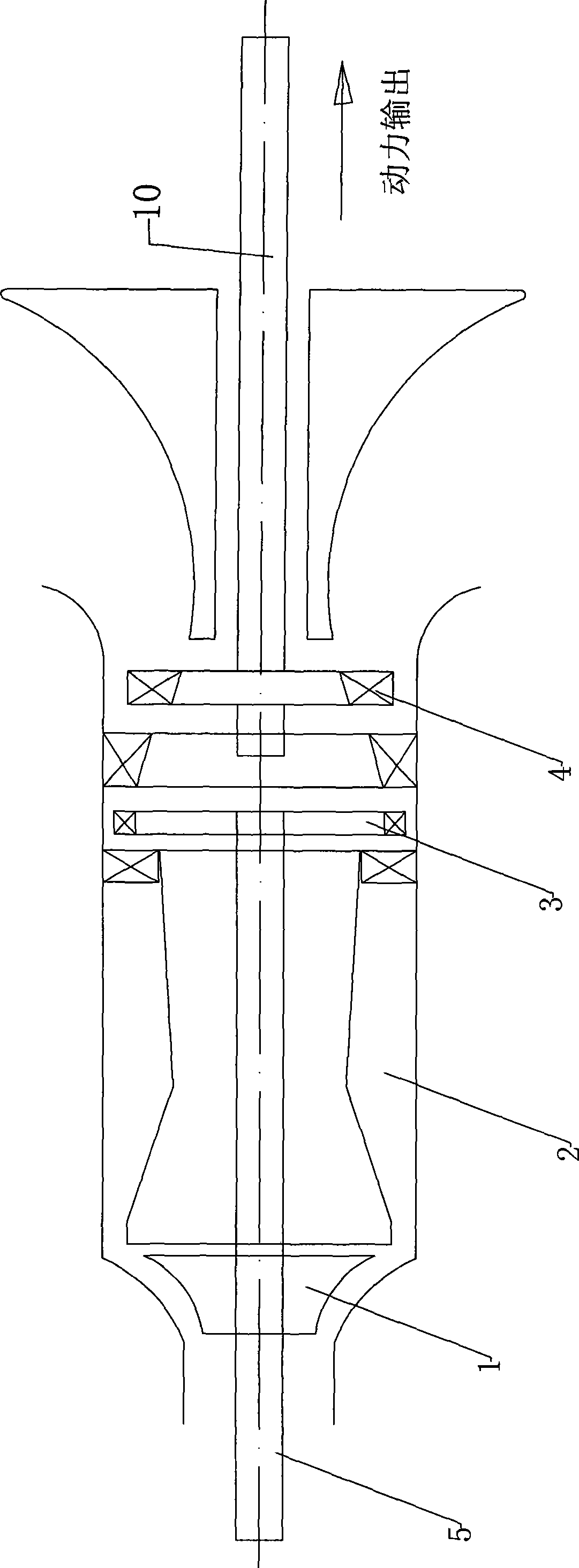

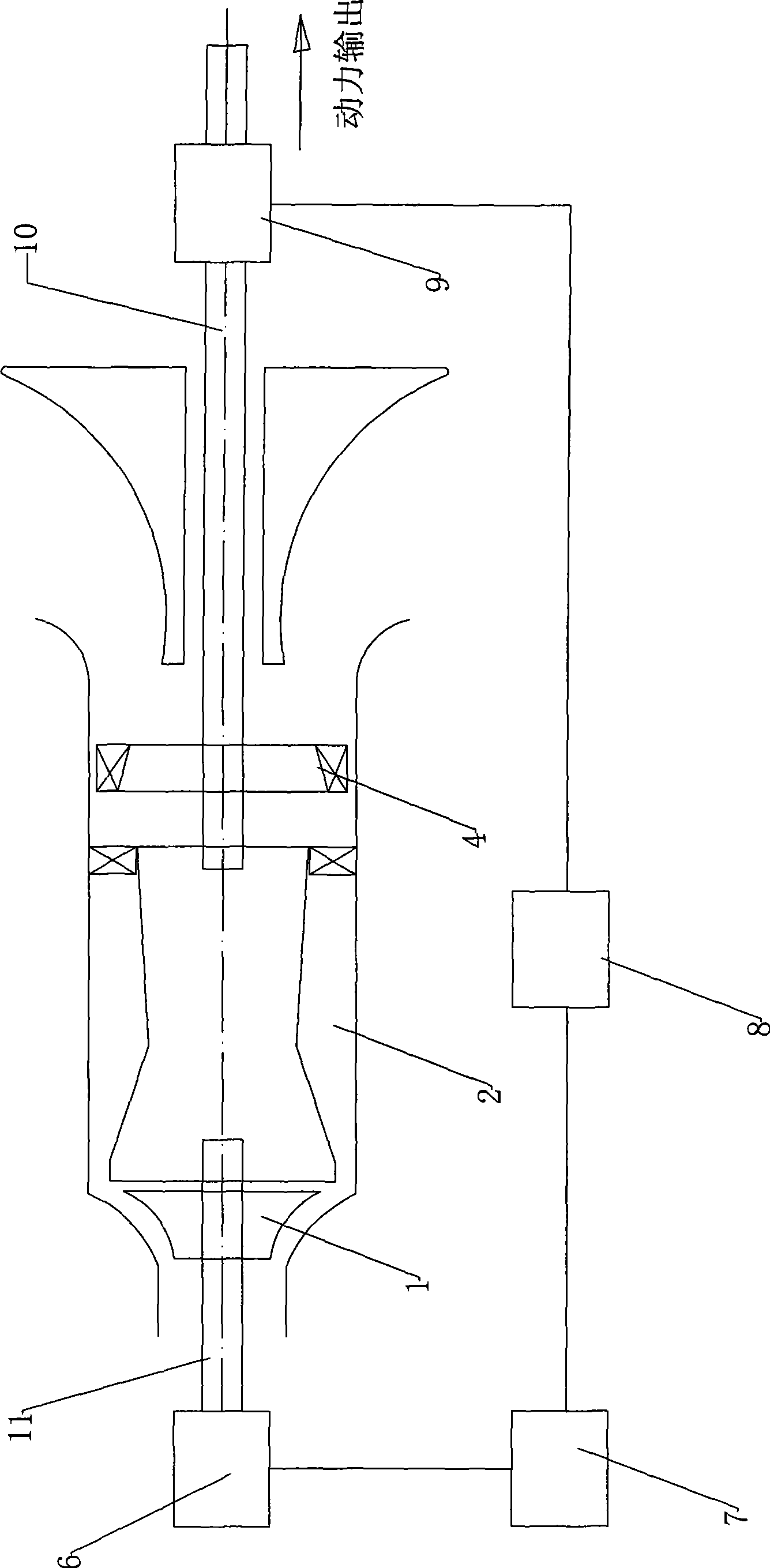

[0031] like figure 1 Shown is the structural diagram of the existing turboshaft engine. It includes a compressor 1 arranged in the casing, a combustion chamber 2 located in the middle of the casing, and a drive turbine 3 located on the right side of the combustion chamber 2 and connected to the compressor 1 through a turbine shaft 5 in rotation. The rotational connection in this specification refers to two or connections that can be rotated synchronously. The right side of the drive turbine 3 is provided with a power turbine 4 (also referred to as "free turbine") for outputting power. The power turbine 4 is rotatably connected with the power shaft 10, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com