Low discharging system of diesel engine used not on road

A diesel engine and low-emission technology, applied in the direction of charging system, mechanical equipment, engine components, etc., can solve the problems affecting the reliability of electronically controlled diesel engines, rising manufacturing and maintenance costs, and harsh working environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

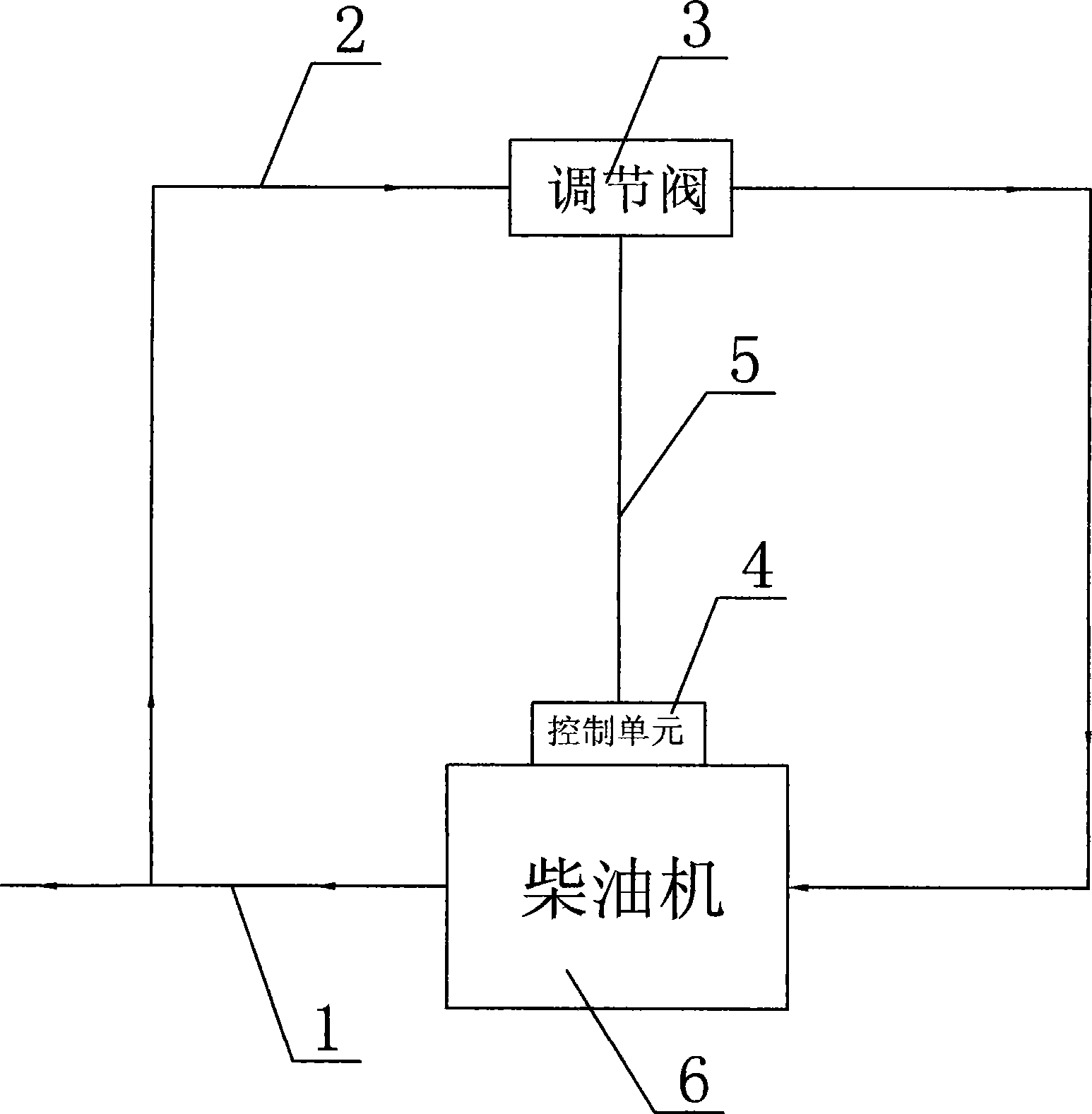

[0011] As shown in the accompanying drawings, the low-emission system for non-road diesel engines includes a main engine 6 equipped with an in-line pump. The main engine 6 of the diesel engine is provided with an exhaust passage 1 through which the combustion chamber of the diesel engine can be combusted to form a It also includes the exhaust gas circulation system (referred to as EGR), in which the exhaust gas recirculation system is a cooled exhaust gas recirculation system or a non-cooled exhaust gas recirculation system, and the exhaust gas is sent to the combustion chamber of the diesel engine through the exhaust gas circulation system for recirculation Combustion reduces the amount of nitrogen oxides produced.

[0012] Among them, the exhaust gas circulation system includes the exhaust gas recirculation pipeline 2, through which the exhaust gas can be recycled, and the combustion temperature in the combustion chamber can be reduced by sending the exhaust gas into the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com