Coal burning boiler

A technology for coal-fired boilers and furnaces, applied in the field of coal-fired boilers, can solve the problems of difficult cleaning, high cost, troublesome storage and transportation, etc., and achieve the effects of widening the application range of coal types, reducing slag combustibles, and saving coal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

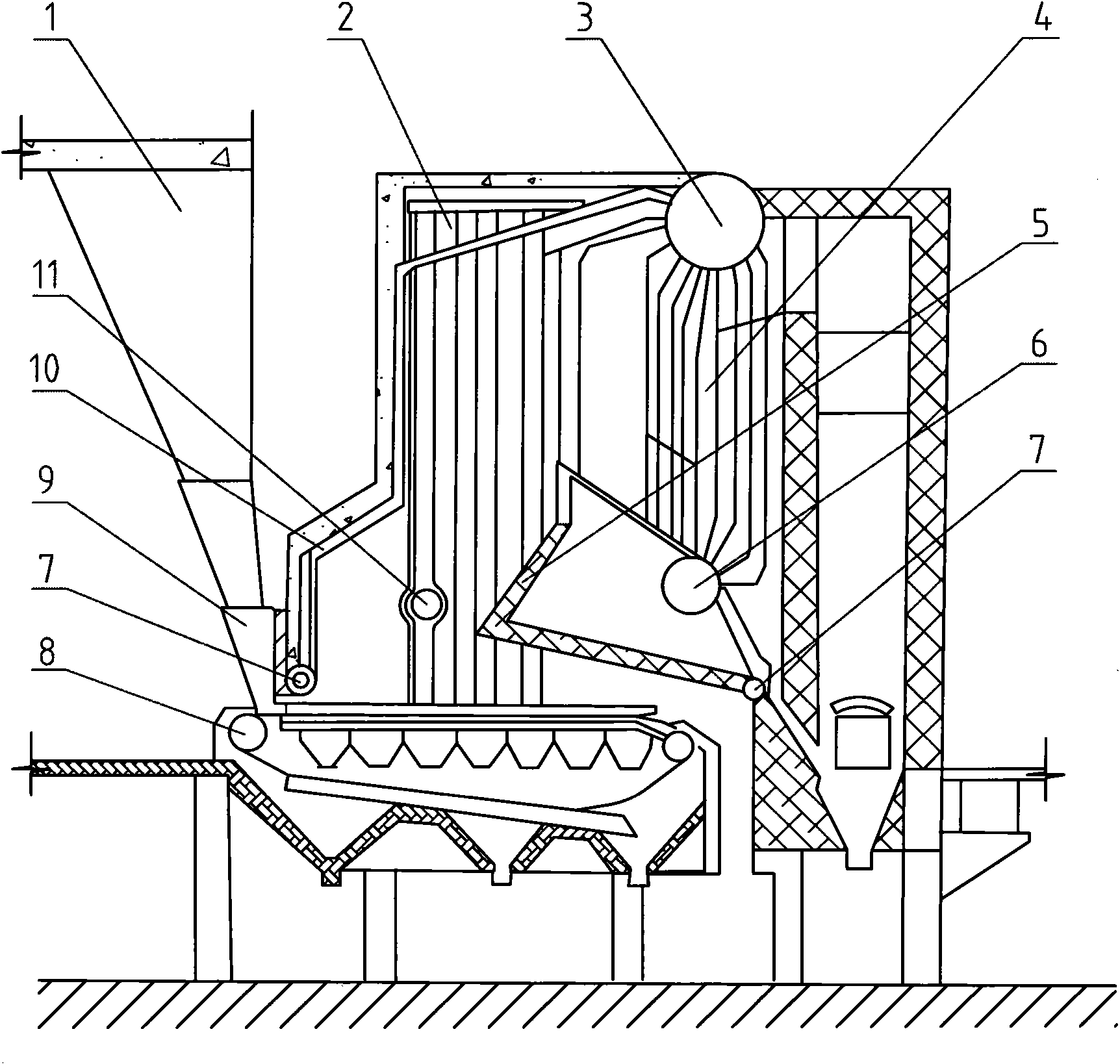

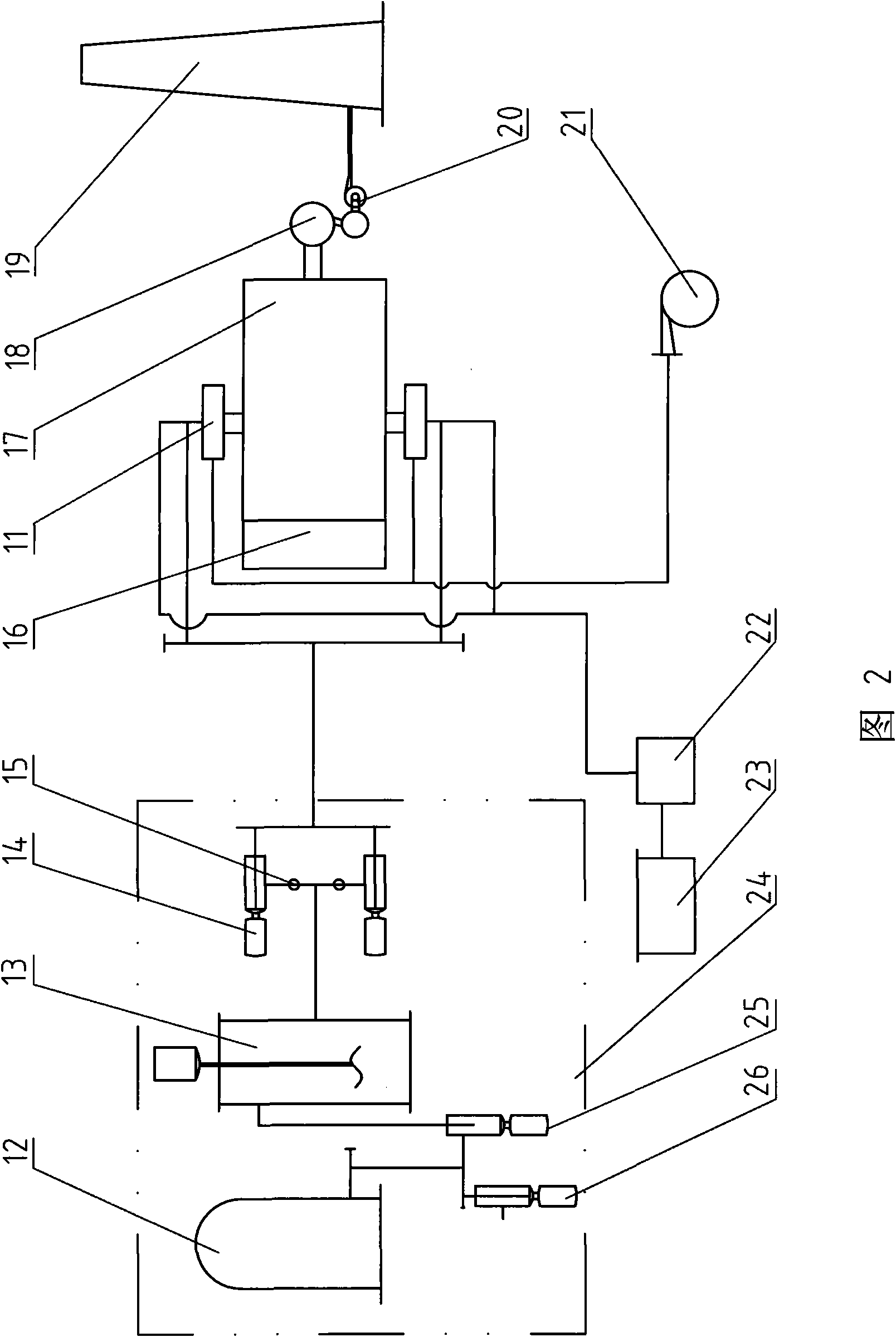

[0024] Refer to the attached figure 1 and 2 The coal-fired boiler of this embodiment includes a chain grate 8 and a coal feeding device passing through the furnace for coal delivery and as a fire bed. The furnace includes a front arch 10 and a rear arch 5, and a water-cooled wall 2 and Its header 7, the coal-fired boiler further includes a coal-water slurry burner 11 and a coal-water slurry delivery system that provides fuel for the coal-water slurry burner, wherein the coal-water slurry burner is located in the middle between the front and rear arches of the furnace, and The chain grate system is used as the ignition device.

[0025] Preferably, the coal-water slurry burner is located at the center of the water-cooled wall in the furnace arch, where the radiation heat of the furnace arch is relatively large, and it is located on the upper part of the fire bed, which facilitates the ignition of the coal-water slurry. On the other hand, the radiant heat to the water wall can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com