Aluminium bearing alloy

一种铝基轴承、铝合金基的技术,应用在发动机曲轴轴承领域,能够解决增加疲劳强度抗磨损性抗卡咬性、抗磨损性/抗卡咬性降低、排除包覆涂层等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

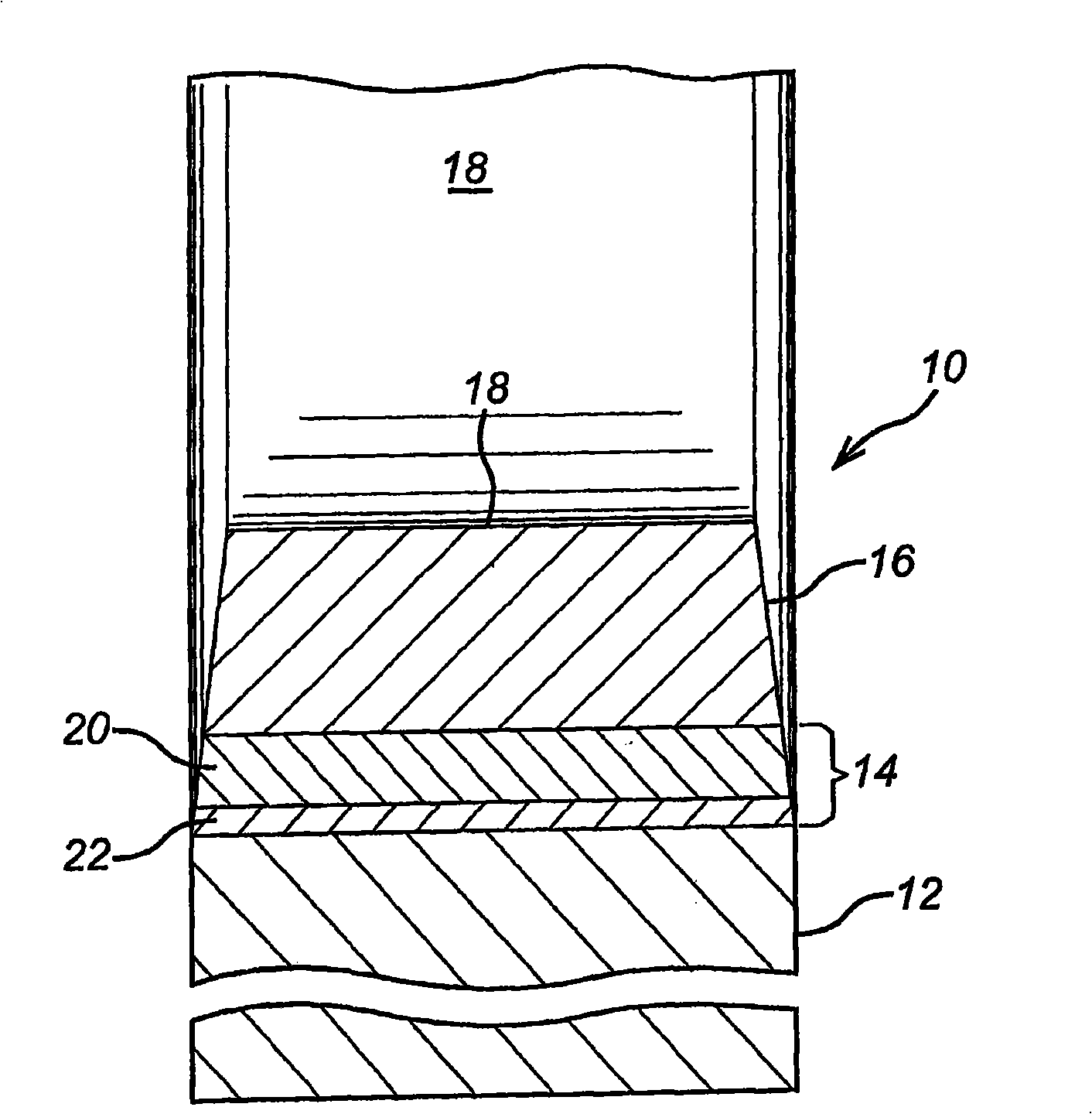

[0021] figure 1 A schematic axial cross-section through a portion of a typical bearing 10 having a bearing alloy liner of the present invention is shown. The bearing comprises a layer 12 of a strong backing material of steel, an intermediate layer 14 and a bearing alloy lining layer 16 with a sliding bearing surface 18 . The intermediate layer 14 itself consists of two layers: a first layer 20 adjacent to the bearing alloy lining 16, the composition of the first layer 20 is Al-0.1Cu-1.2Mn, accounting for about 90% of the total thickness of the intermediate layer 14; The second layer 22, the composition of the second layer 22 is Al-8% Si, accounts for about 10% of the total thickness of the middle layer 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com