Preparation method of fresh-keeping film with high carbon dioxide permeability and application thereof

A technology with carbon dioxide and high permeability, which can be used in applications, fruit and vegetable preservation, food preservation, etc., and can solve problems such as insufficient mechanical strength, loss of permeability selectivity, and poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

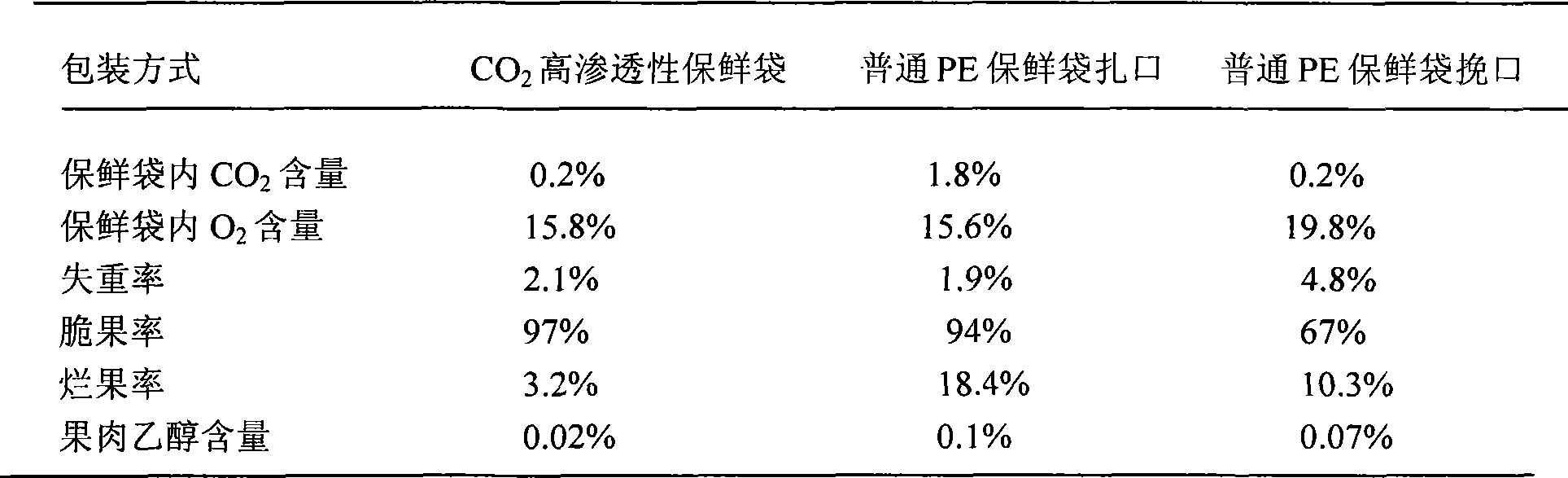

[0013] Mix 100mL of 20% polyethyleneimine (molecular weight 75000) aqueous solution with 5% polyvinyl alcohol (molecular weight 18000, alcoholysis degree 95%) aqueous solution 200mL, defoam and filter and evenly coat on the blue non-woven fabric On, coating amount 200mL / m 2 . Afterwards, put it flat into a clean constant temperature and humidity chamber set at 50°C for 18 hours, then raise the temperature to 130°C and maintain it for 1 hour to obtain a carbon dioxide highly gas-permeable film. The carbon dioxide permeability coefficient of the membrane is 4.5×10 by air permeability measurement. 6 mL / m 2 ·d·atm (the partial pressure difference of carbon dioxide on both sides of the membrane is 1% of atmospheric pressure), and the carbon dioxide / oxygen permeation ratio is 386:1. The obtained film is cut into a square of 10cm * 15cm, and the edge of the square film is heat-sealed on the central part of one side of a common polyethylene fresh-keeping bag whose specification is ...

Embodiment 2

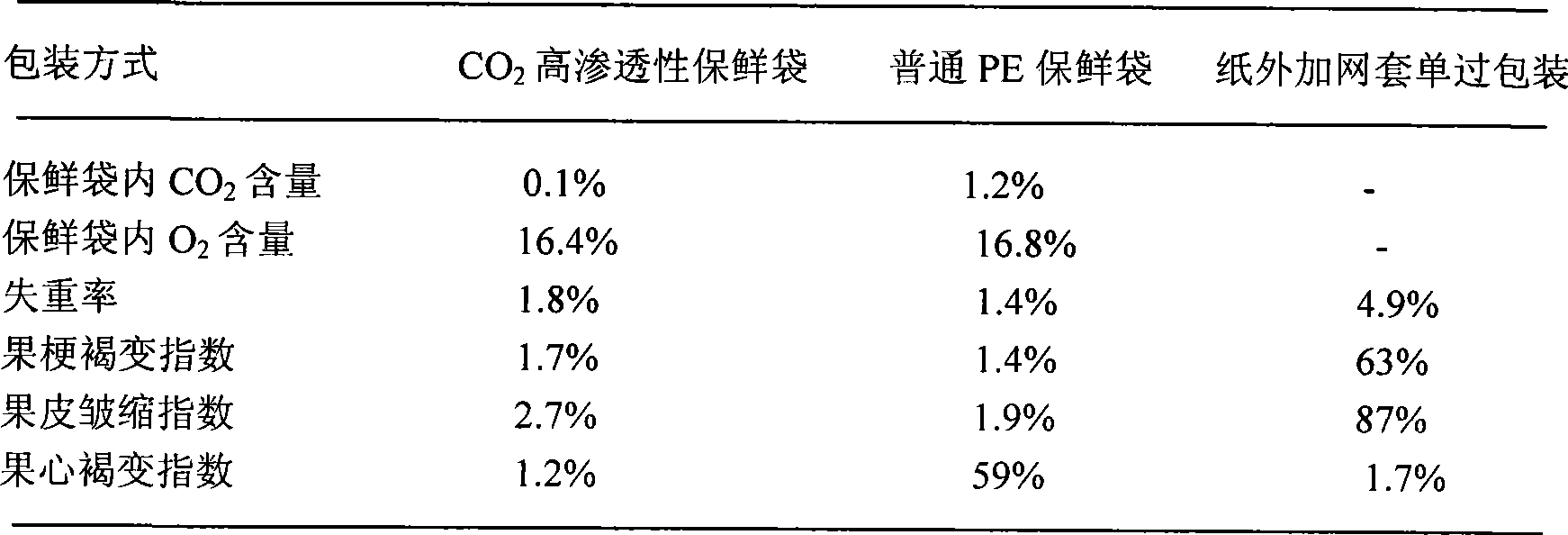

[0017] Mix 50mL of 25% polyethyleneimine (molecular weight 75000) aqueous solution with 5% polyvinyl alcohol (molecular weight 18000, alcoholysis degree 95%) aqueous solution 200mL, defoam and filter and evenly coat on the blue non-woven fabric On, coating amount 150mL / m 2 . Afterwards, put it flat into a clean constant temperature and humidity chamber set at 60°C for 20 hours, then raise the temperature to 140°C and maintain it for 1 hour to prepare a carbon dioxide highly gas-permeable film. The carbon dioxide permeability coefficient of the membrane is 4.8×10 after air permeability measurement. 6 mL / m 2 ·d·atm (the partial pressure difference of carbon dioxide on both sides of the membrane is 1% of atmospheric pressure), and the carbon dioxide / oxygen permeation ratio is 353:1. The obtained film is cut into a square of 10cm * 15cm, and it is heat-sealed on the common polyethylene fresh-keeping bag of the same specification in the same manner as the previous example. Pack...

Embodiment 3

[0021] Among the above-mentioned examples: use polyethyleneimine with molecular weight between 2000-750000, the concentration of its solution is 10%; use polyvinyl alcohol with molecular weight between 10000-50000, alcoholysis degree more than 90%, the concentration of its solution is 1 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com