Sour milk

A yogurt and fresh technology, applied in the field of dairy products, to achieve the effect of rich milk flavor, soft taste and strong social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

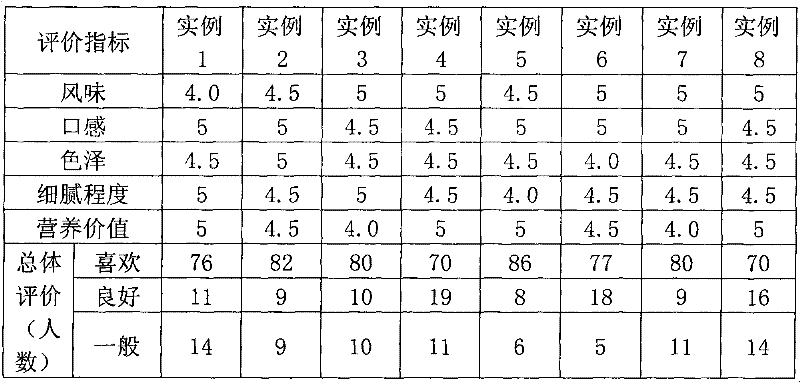

Examples

Embodiment 1

[0039] Transglutaminase: 0.75 parts by weight

[0040] δ-gluconolactone: 15 parts by weight

[0041] Probiotic powder (Lactobacillus bulgaricus: Streptococcus thermophilus: Lactobacillus casei: Lactobacillus reuteri ratio is 3:3:2:2): 0.002 parts by weight

[0042] The above-mentioned concentrated fresh milk is prepared by adding 0.15 parts by weight of lactase and concentrating to 35%-40% after being treated in a water bath.

[0043] A method for preparing non-fermented yogurt, the steps are:

[0044] (1) Add lactase to fresh milk and place it in a water bath at 37°C for 2 hours;

[0045] (2) heating the above-mentioned treated fresh milk to 63°C, and sterilizing for 0.5 hours;

[0046] (3) Concentrating the sterilized fresh milk to 40% of the original volume to form concentrated fresh milk;

[0047] (4) Add probiotic powder to the above-mentioned concentrated fresh milk, and mix well;

[0048] (5) Heat the above concentrated fresh milk to 40°C, add transglutaminase powd...

Embodiment 2

[0054] Transglutaminase: 0.75 parts by weight

[0055] δ-gluconolactone: 15 parts by weight

[0056] Probiotic powder (Lactobacillus bulgaricus: Streptococcus thermophilus: Lactobacillus casei: Lactobacillus reuteri ratio is 3:3:2:2): 0.002 parts by weight

[0057] Adding chocolate chips and almonds: 2 parts by weight

[0058] The above-mentioned concentrated fresh milk is prepared by adding 0.15 parts by weight of lactase and concentrating to 35%-40% after being treated in a water bath.

[0059] A method for preparing non-fermented yogurt, the steps are:

[0060] (1) Add lactase to fresh milk and place it in a water bath at 37°C for 2 hours;

[0061] (2) heating the above-mentioned treated fresh milk to 63°C, and sterilizing for 0.5 hours;

[0062] (3) Concentrating the sterilized fresh milk to 40% of the original volume;

[0063] (4) Add sterilized additives to the above-mentioned concentrated fresh milk: chocolate chips and almonds (whole or broken);

[0064] (5) Add ...

Embodiment 3

[0071] Transglutaminase: 0.75 parts by weight

[0072] δ-gluconolactone: 15 parts by weight

[0073] Probiotic powder (Lactobacillus bulgaricus: Streptococcus thermophilus: Lactobacillus casei: Lactobacillus reuteri ratio is 3:3:2:2): 0.002 parts by weight

[0074] Additive sweet corn kernels: 1 part by weight

[0075] The above-mentioned concentrated fresh milk is prepared by adding 0.15 parts by weight of lactase and concentrating to 35%-40% after being treated in a water bath.

[0076] A method for preparing non-fermented yogurt, the steps are:

[0077] (1) Add lactase to fresh milk and place it in a water bath at 39°C for 2 hours;

[0078] (2) heating the above-mentioned treated fresh milk to 63°C, and sterilizing for 0.5 hours;

[0079] (3) Concentrating the sterilized fresh milk to 40% of the original volume;

[0080] (4) Adding sterilized additives to the concentrated fresh milk: sweet corn kernels;

[0081] (5) Add probiotic powder to the concentrated fresh milk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com