Method of preparing pure natural chicken extract flavour liquid and flavour liquid prepared by utilizing same

A production method and technology of seasoning liquid, which are applied in application, food preparation, food science and other directions, can solve the problems of low proportion of authentic ingredients of natural chicken, which is not conducive to human health, etc., and achieve rich nutrition, delicious taste and mellow aroma, The unique effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

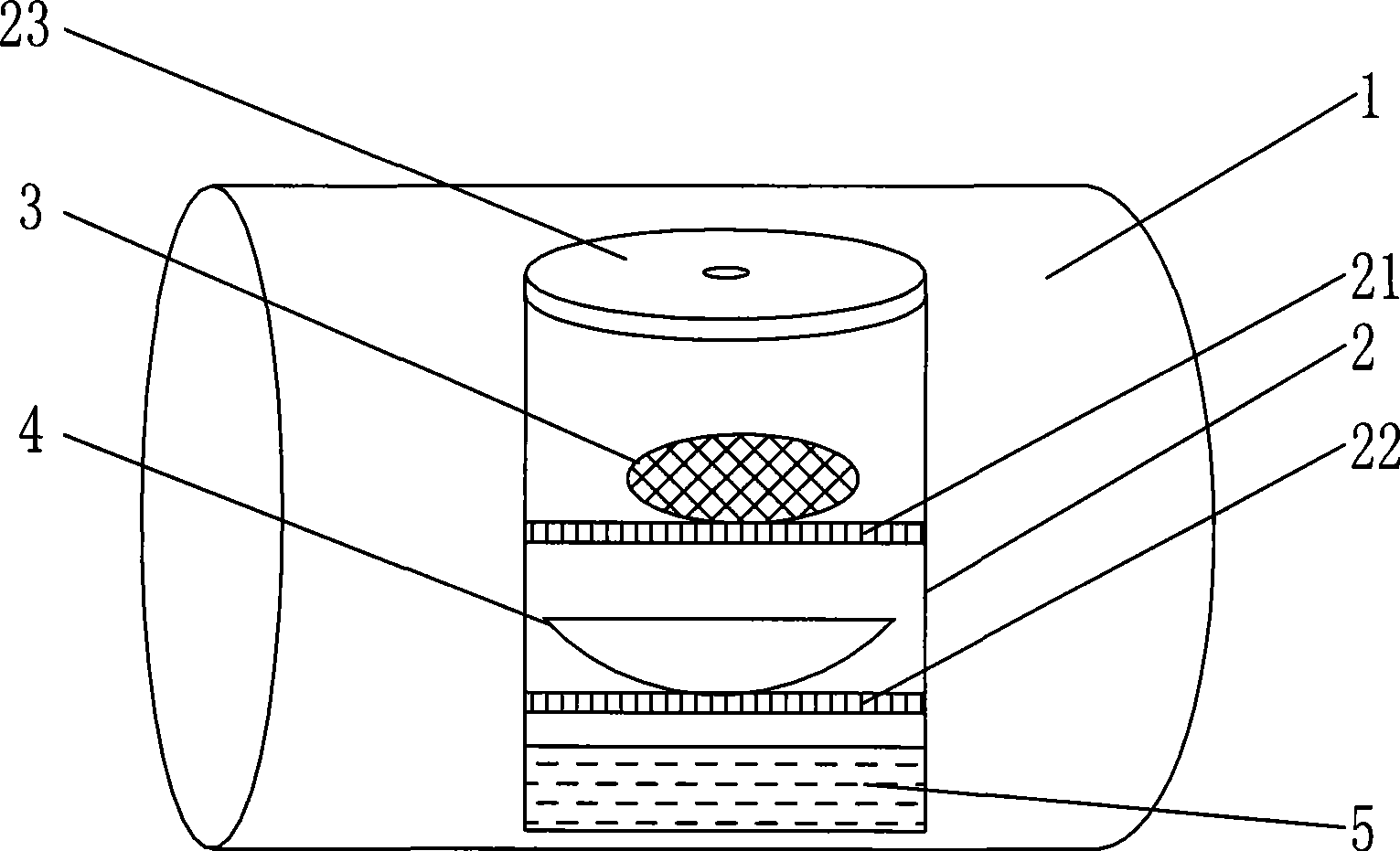

Image

Examples

Embodiment 1

[0042] First, take 10kg of fresh chicken rack and cut into pieces, add 400g of salt, 100g of glucose, 50g of white wine, 20g of phosphate, 2g of Yunnan green pepper oleoresin, roll and knead evenly, and marinate and ferment at 3°C for 72 hours; then put it in the above distillation equipment 1.5 hours under the pressure of 0.15MPa; finally, collect the distillate, cool it to remove oil, filter it through a 100-mesh sieve, heat it at 100°C for 10 minutes, and then fill it to obtain 1.68kg of clear juice.

Embodiment 2

[0044] First, take 10kg of fresh chicken racks and cut them into pieces, add 300g of salt, 150g of glucose, 32g of white wine, 25g of phosphate, 2.5g of Yunnan green pepper oleoresin, roll and knead evenly, and marinate and ferment at 2°C for 48 hours; then put it in the above distillation In the equipment, steam under 0.16MPa pressure for 2 hours; finally, collect the distillate, cool it to remove oil, filter it through a 100-mesh sieve, heat it at 100°C for 10 minutes, and then fill it to obtain 1.70kg of clear juice.

Embodiment 3

[0046]First, take 10kg of fresh chicken rack and cut into pieces, add 500g of salt, 50g of glucose, 60g of white wine, 30g of phosphate, 3g of Yunnan green pepper oleoresin, roll and knead evenly, pickle and ferment at 4°C for 60 hours at low temperature; then put it in the above distillation equipment In the process, steam for 2 hours under 0.15MPa pressure; finally, collect the distillate, cool it to remove oil, filter it through a 100-mesh sieve, heat it at 100°C for 10 minutes, and then fill it to obtain 1.69kg of clear juice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com