Method for preparing organic-inorganic hybrid evaporation alcohol permselective membrane

A technology of preferential alcohol permeation membrane and pervaporation, which is applied in the field of preparation of organic-inorganic hybrid pervaporation preferential alcohol permeation membrane, can solve the problems of affecting membrane separation stability, easy formation of defects in phase interface, etc., so as to avoid the increase of interface defects. , Improve separation performance, weaken the effect of interface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The modified microporous molecular sieve was prepared according to the aforementioned method for preparing the modified microporous molecular sieve. Table 1 shows the modification reagents and modification conditions used in the preparation of six modified microporous molecular sieves. The obtained modified microporous molecular sieves are all in the form of particles, with a particle size of less than 1 μm and a specific surface area of 280-300 m 2 / g.

[0023] Table 1 Modification reagents and modification conditions used in the preparation of modified microporous molecular sieves

[0024]

Embodiment 2

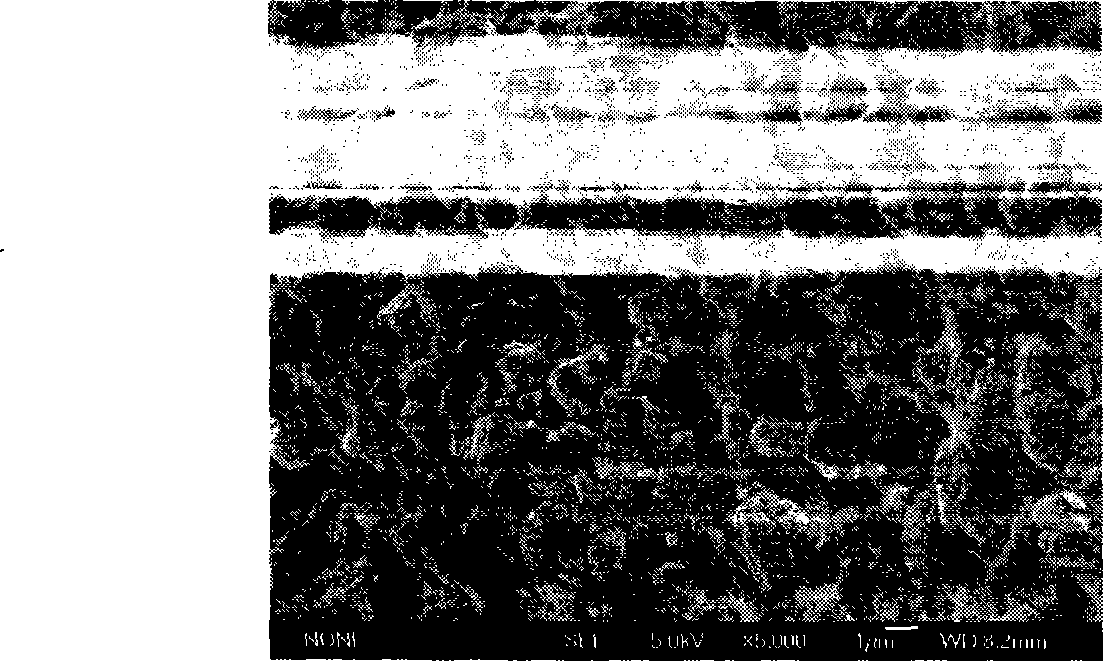

[0026] Using n-heptane as a solvent, the hydroxyl silicone rubber was blended with the modified microporous molecular sieve 1 obtained in Example 1, the mass percent of the silicone rubber was 18%, and the mass percent of the modified microporous molecular sieve 1 was 26%. The above mixing system is vigorously stirred for 6-8 hours to ensure that the modified microporous molecular sieve is uniformly dispersed in the silicone rubber, and after the solution is left to stand for 30 minutes, the modified microporous molecular sieve has no sedimentation phenomenon. Coat the mixed solution on a plexiglass plate to form a film, place it at room temperature for 8 hours to volatilize the solvent, then keep it in a vacuum oven at 60°C for 12 hours, take out the film after cooling down, soak it in ethanol aqueous solution overnight, and test the film performance . The membrane obtained is under 36 ℃, 220Pa vacuum degree, to the selectivity of the ethanol / water solution of 5.97 (ml / ml)% t...

Embodiment 3

[0028] Using n-heptane as a solvent, the hydroxyl silicone rubber was blended with the modified microporous molecular sieve 1 obtained in Example 1, the mass percent of the silicone rubber was 21.6%, and the mass percent of the modified microporous molecular sieve 1 was 32.4%. The above mixing system is vigorously stirred for 6-8 hours to ensure that the modified microporous molecular sieve is uniformly dispersed in the silicone rubber, and after the solution is left to stand for 30 minutes, the modified microporous molecular sieve has no sedimentation phenomenon. The mixed solution was coated on a steel plate to form a film, and placed at room temperature for 8 hours to evaporate the solvent, and then kept in a vacuum oven at 100°C for 12 hours, the film was cooled and taken out, soaked in ethanol aqueous solution overnight, and the film performance was tested. The obtained membrane has a selectivity of 26 to a concentration of 5.97 (ml / ml)% ethanol / water solution at 36°C and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com