Microwave chemical reaction device using dielectric radiator

A chemical reaction and radiator technology, applied in the field of microwave chemical reaction devices, can solve problems such as increased reflection of microwave energy, uneven temperature, damage, etc., to meet power and volume and pressure bearing capacity, reduce manufacturing costs, and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

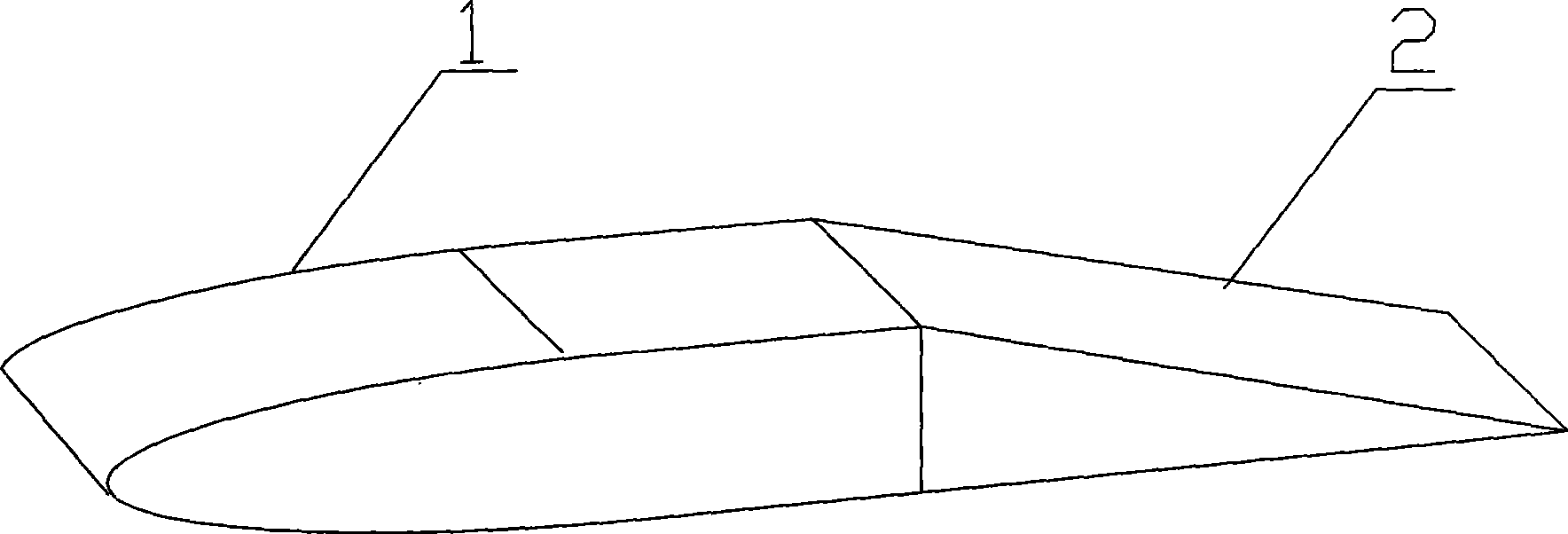

[0045] The microwave chemical reaction device in this embodiment works under normal pressure, the reaction vessel 5 is made of stainless steel, the volume of the reaction vessel is 30 liters, a set of microwave transmission system is set, the microwave source power is 1kW, and the microwave frequency is 2450MHz. The microwave transmission system includes a dielectric radiator 10 and a waveguide 8 . The structure of the dielectric radiator 10 is as figure 1 As shown, it is composed of radiation section 1 and impedance transformation section 2. The longitudinal section of radiation section 1 is a combination of semi-ellipse and rectangle. The longitudinal section of impedance transformation section 2 is a triangle. Radiation section 1 and impedance transformation section 2 are an integrated structure. (Integral structure), made of quartz glass. The waveguide 8 is a BJ-22 copper waveguide, and its end is provided with a flange 7 for connection. The assembly method of the reacti...

Embodiment 2

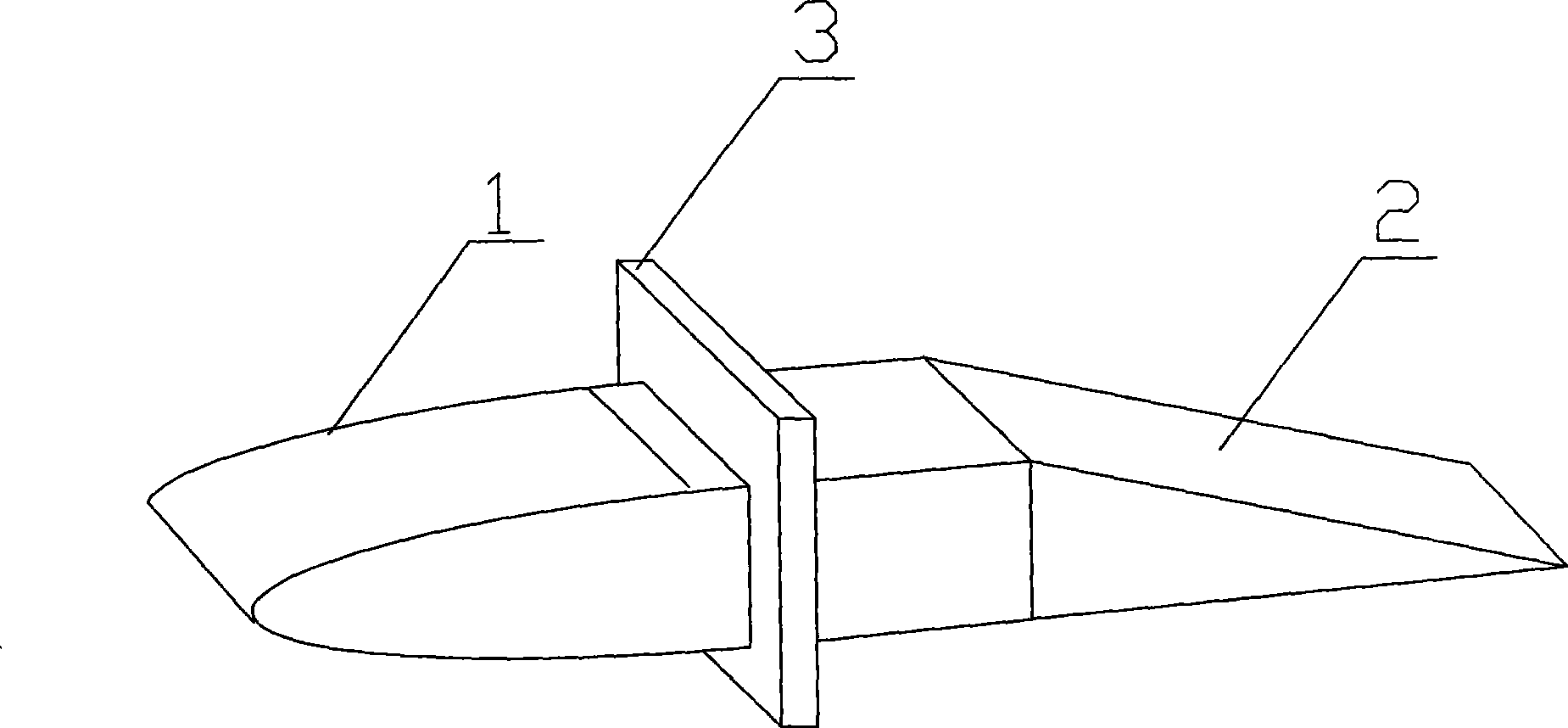

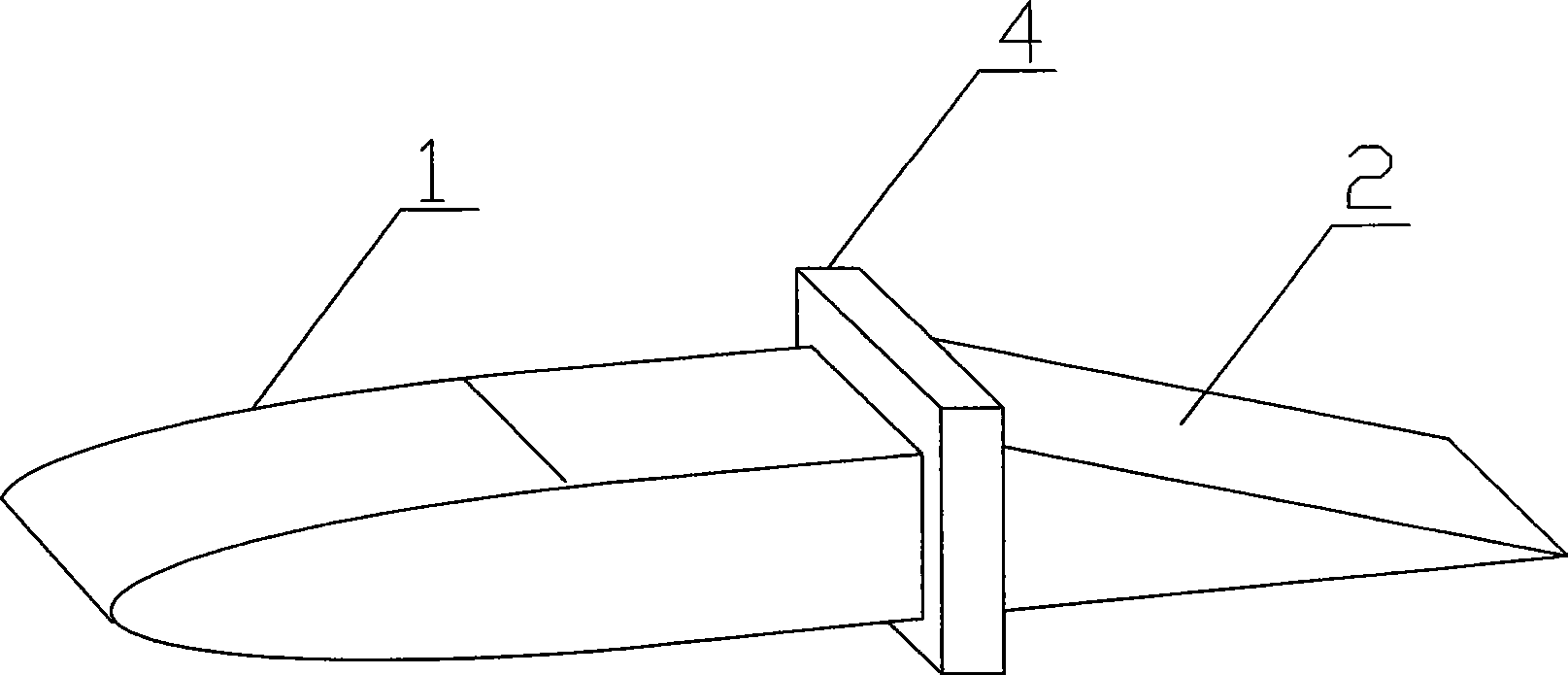

[0048] The microwave chemical reaction device in this embodiment works under pressure (pressure 1.5MPa), the power is 12kW, and the operating frequency is 2450MHz. Its reaction vessel 5 is made of stainless steel, and its volume is 300 liters, and its internal diameter is 90 centimeters. Four sets of Microwave transmission systems that are independent of each other and have the same structure, each microwave transmission system includes a dielectric radiator 10 and a waveguide 8 . The structure of the dielectric radiator 10 is as Figure 4 As shown, it consists of radiating section 1, impedance transformation section 2, fastening plate 3 and dielectric baffle 4, fastening plate 3 is located on radiating section 1 and is an integrated structure with radiating section 1, radiating section 1, dielectric baffle 4. Impedance transformation section 2 is manufactured separately and combined during installation; the longitudinal section of radiation section 1 is a combination of semi-...

Embodiment 3

[0053] The microwave chemical reaction device in this embodiment works under pressure (pressure 1.0MPa), the power is 90kW, and the operating frequency is 2450MHz. The reaction vessel 5 is made of stainless steel and has a volume of 2000 liters. There are 30 sets of five layers that are independent of each other. And the microwave transmission system with the same structure. The installation positions of 30 sets of microwave transmission systems on the reaction vessel 5 and the assembly methods of the dielectric radiator 10, waveguide 8 and microwave source 9 in each set of microwave transmission systems are as follows: Figure 10 , Figure 11 and Figure 12 shown. The five-layer microwave transmission system installed on the side wall of the reaction vessel 5 is installed at an interval of 30 cm along the axial direction of the reaction vessel. Each set of microwave transmission systems at the same height is installed at an interval of 60°, and two sets of microwave transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com