High-piezoelectricity plasma ceramic combustion engine

A high-voltage electricity, internal combustion engine technology, applied in mechanical equipment, engine components, machines/engines, etc., to achieve the effect of improving work efficiency and saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

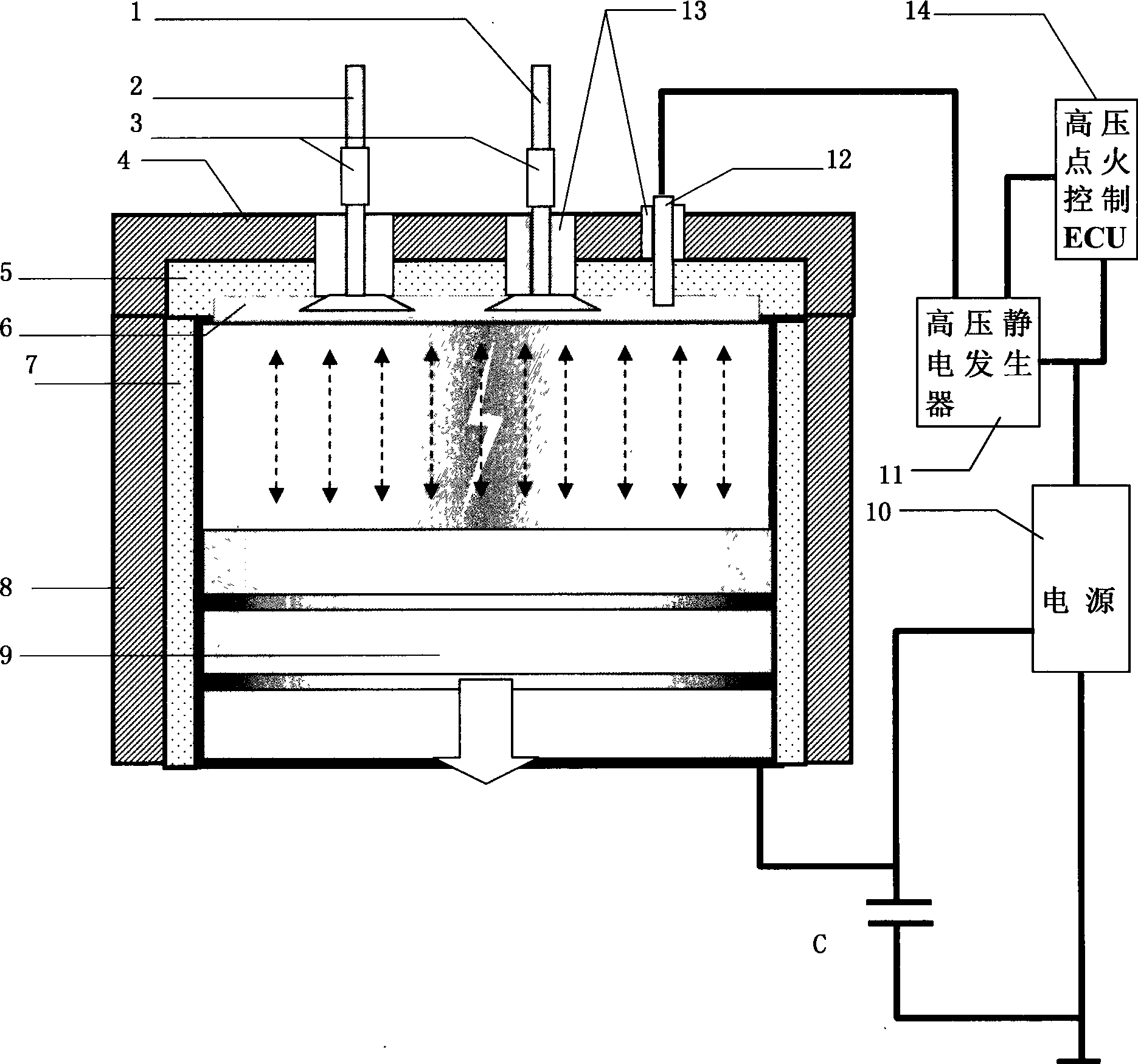

[0012] Attached below figure 1 And embodiment further illustrate the present invention.

[0013] The basic structure of the internal combustion engine of the present invention is consistent with the existing engine structure. On the basis of the original technology, an insulating ceramic cylinder liner 7 is embedded in the metal cylinder block 8, and a cylinder head ceramic insulating plate 5 is also embedded in the metal cylinder head 4. Spread high-voltage electric metal plate 6 on the outer wall of cylinder head ceramic insulating plate 5 again, and this metal plate is connected with metal conduction rod 12. The valve stems of the intake valve 1 and the exhaust valve 2 are connected with a ceramic connecting rod 3, and an insulating ceramic sleeve 13 is arranged between the metal conduction rod 12, the exhaust valve 1, the intake valve 2 and the metal cylinder head 4, Make valves and metal cylinders non-conductive.

[0014] The specific working process is: when the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com