In-situ synthesis method for preparing tin-carbon/core-shell nano-particle fully filled carbon nano-tube composite anode material

A carbon nanotube composite and nanoparticle technology, applied in electrode manufacturing, battery electrodes, electrical components, etc., can solve the problems of uneven distribution, low product structure purity, low filling efficiency, etc., and improve the volume specific capacity and weight ratio. The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

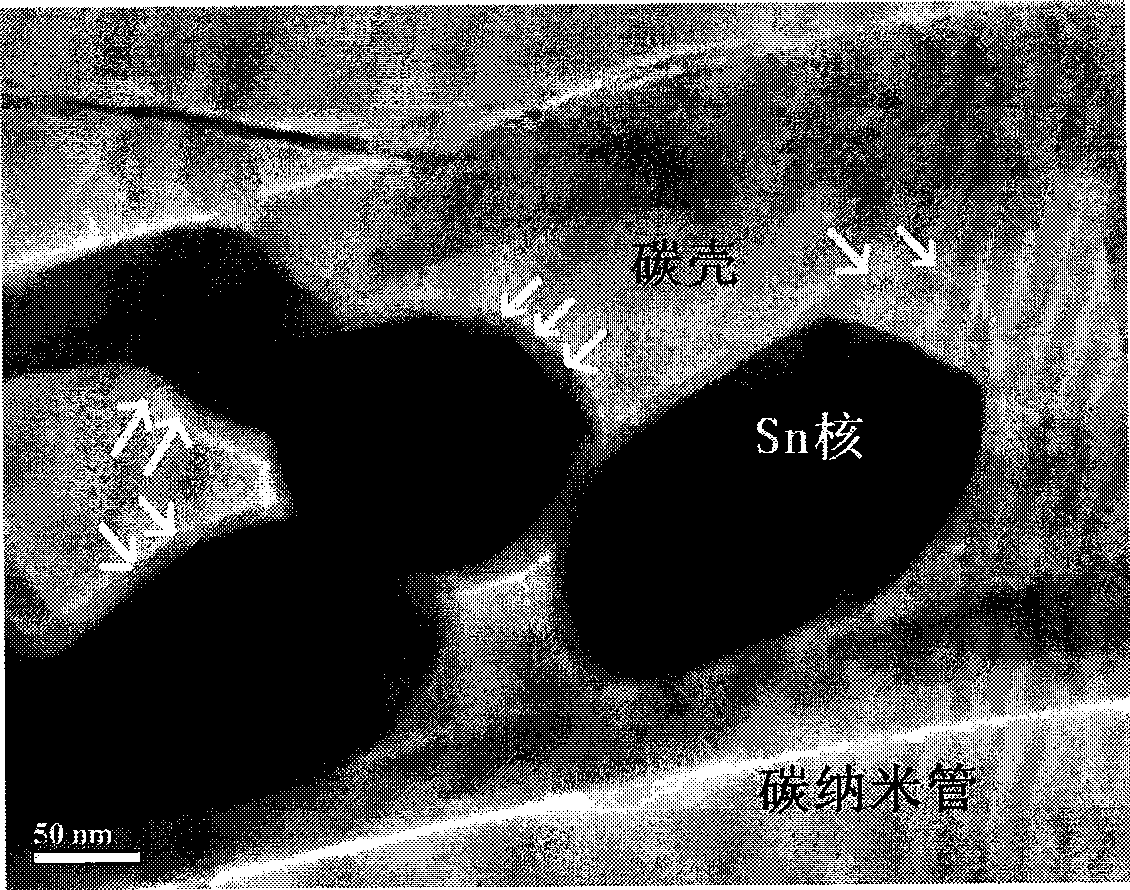

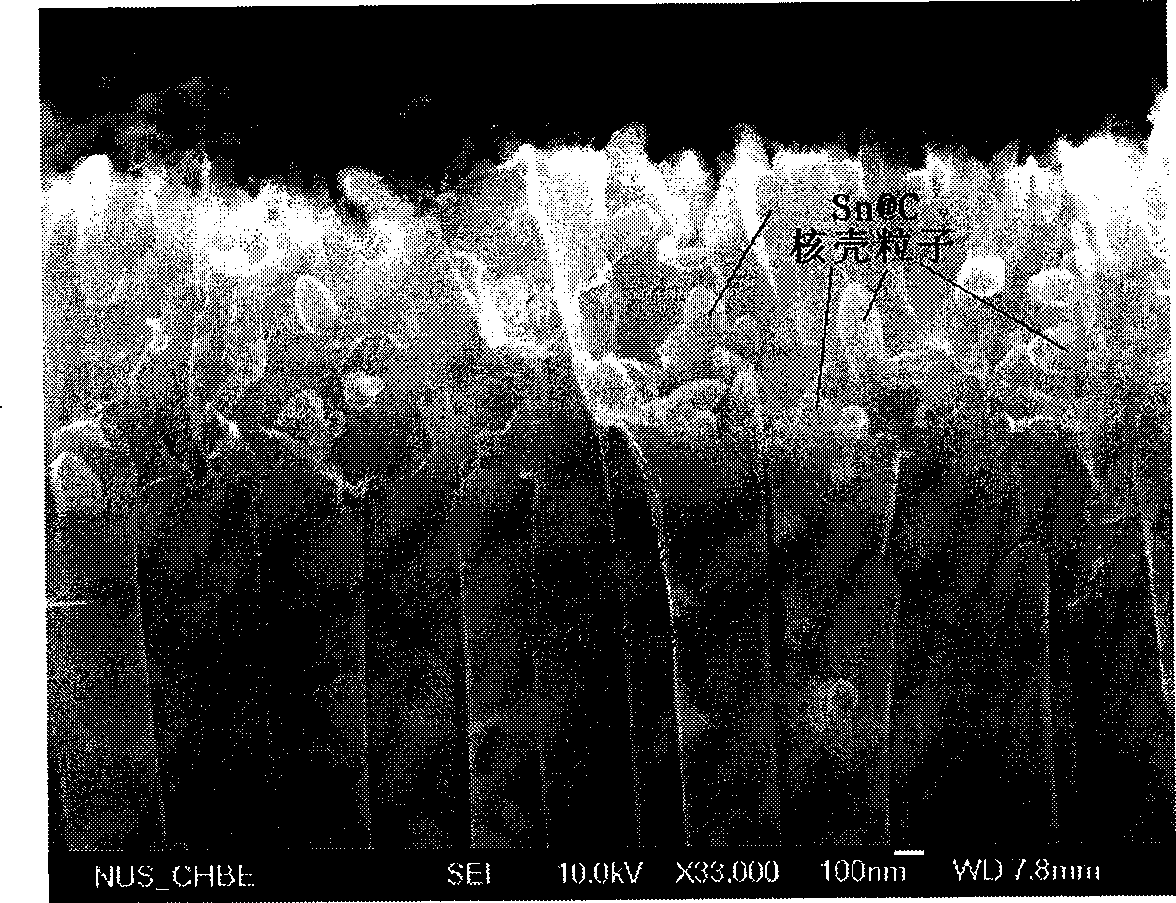

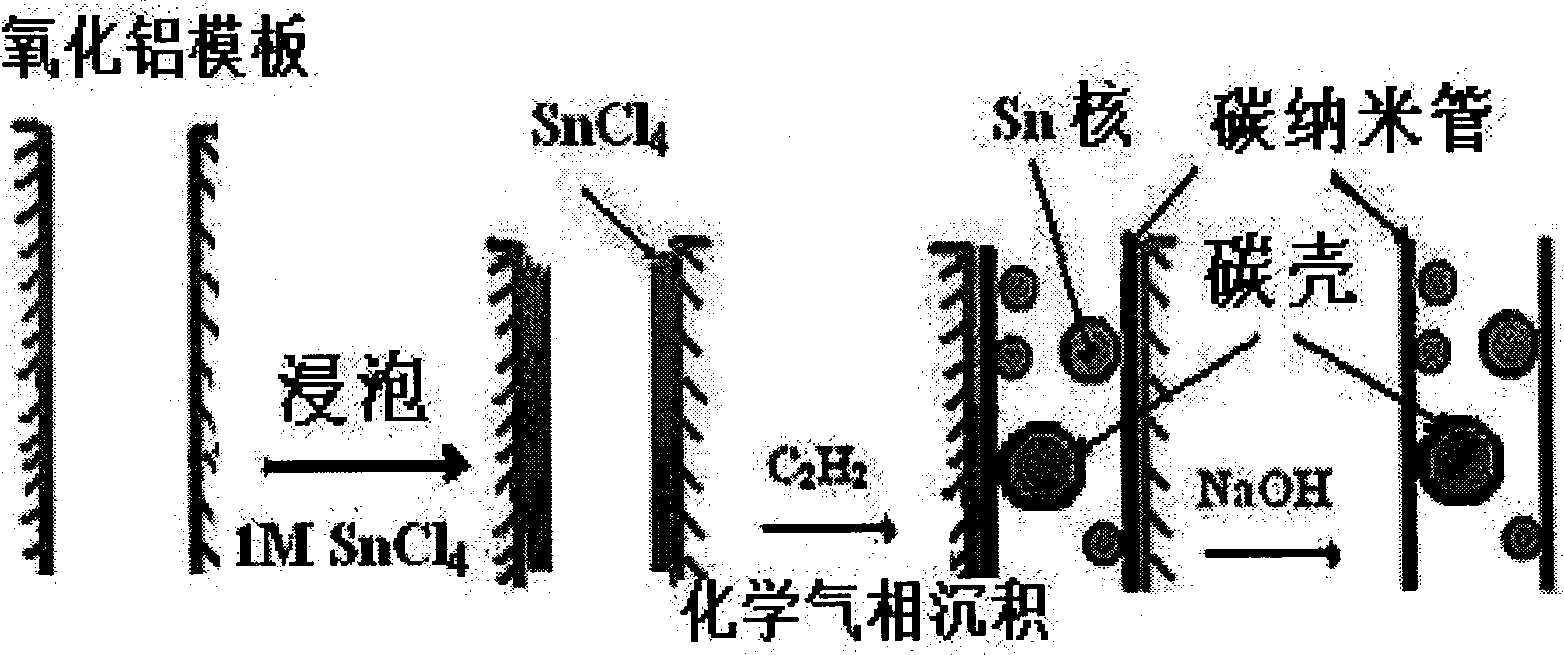

[0016] A porous anodized aluminum film (pore size about 200nm) was placed in 1.0M SnCl 4 Place in the aqueous solution for 3 to 5 hours, then dry in an oven at 70°C for 5 hours, then place the aluminum oxide film in a tube furnace to heat, and feed 200 sccm with a volume percentage of 10% C 2 h 2 and 90%N 2 The mixed gas formed, after passing the mixed gas for 1 hour, began to heat up, heated to 650°C at a heating rate of 3-10°C / min, continued for 3 hours, continued to pass the mixed gas until the tube furnace naturally cooled to room temperature, and then used 6.0M Soak in NaOH aqueous solution for 1 hour to remove the aluminum oxide film, collect the remaining insoluble matter, wash with a large amount of deionized water, and dry the product. The final powder obtained is the product in which Sn@C core-shell nanoparticles are completely filled with carbon nanotubes. This product is in figure 1 Field Emission Scanning Electron Microscope (FESEM) images show that some nanopa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com