Bridge type mixing rectification circuit

A technology of mixed rectification and rectification circuit, which is applied to conversion equipment with intermediate conversion to AC, irreversible AC power input conversion to DC power output, etc., which can solve the problems of difficult driving, large diode voltage drop, and low overall efficiency. Achieve the effect of simple and convenient driving circuit, improved device reliability, and reduced number of winding turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

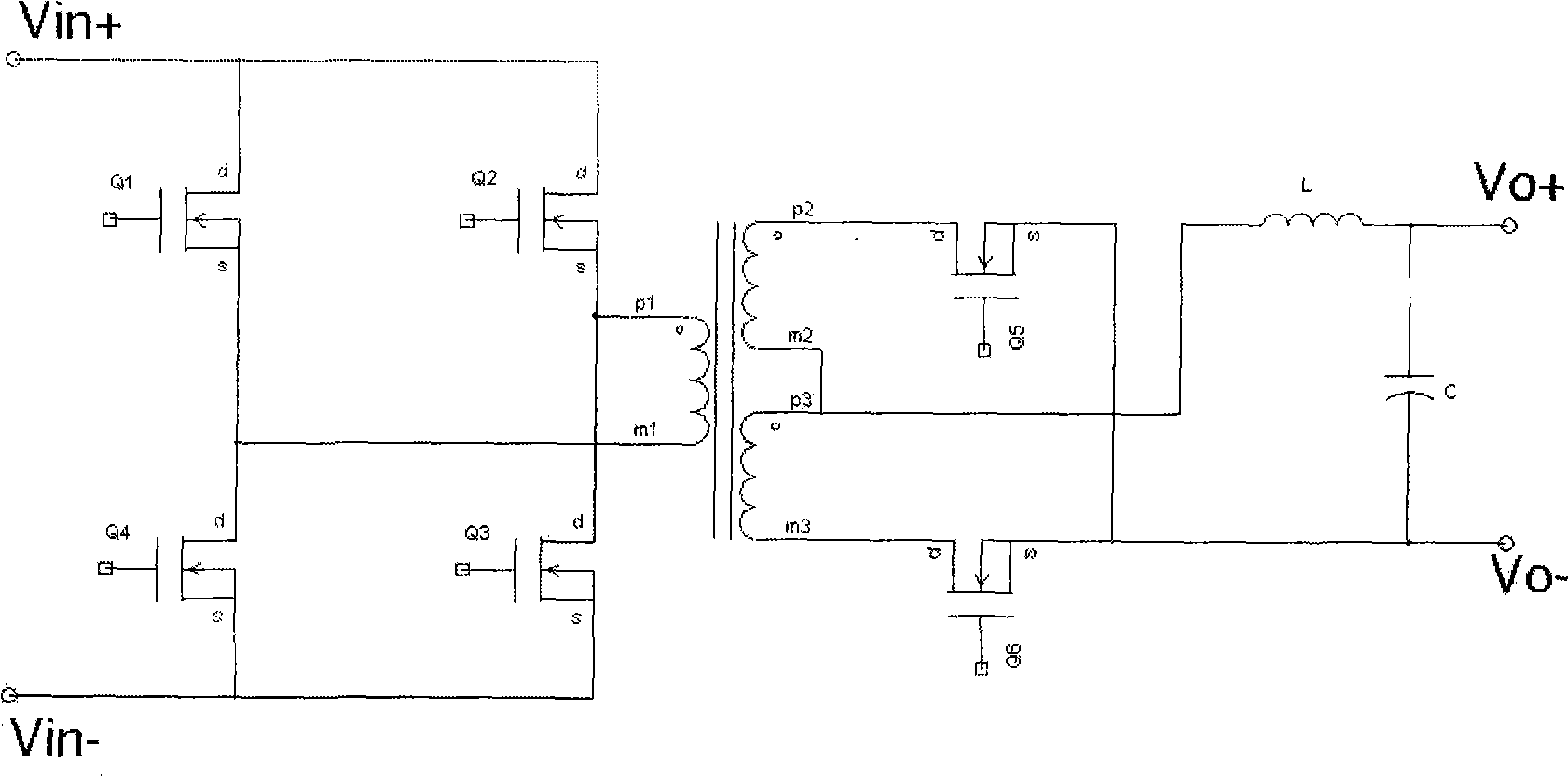

[0022] Such as Figure 4 As shown, it is a circuit diagram of Embodiment 1 of the present invention, and the circuit is used in combination with a hybrid rectifier circuit and a primary-side full-bridge circuit. In ordinary DC / DC converters, especially for medium power converters, in order to improve efficiency, a bridge rectifier circuit is often used on the input side, which is four synchronous rectifier tubes Q1, Q2, Q3, Q4, the four The synchronous rectifier is an N-channel metal oxide semiconductor field effect transistor. The output side includes: two synchronous rectifiers Q5, Q6 and two diodes D1, D2, the above two synchronous rectifiers Q5, Q6 are located at the lower end of the bridge rectifier circuit; the above two diodes D1, D2 are located at the bridge rectifier the upper end of the rectifier circuit.

[0023] The synchronous rectifiers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com