Amoxicillin dispersible tablet and production method thereof

A technology of amoxicillin and amoxicillin technical, which is applied in the field of amoxicillin dispersible tablets and its production, can solve the problems of product quality stability, complex process flow, etc., and achieve the elimination of coating process and short process flow , taste improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

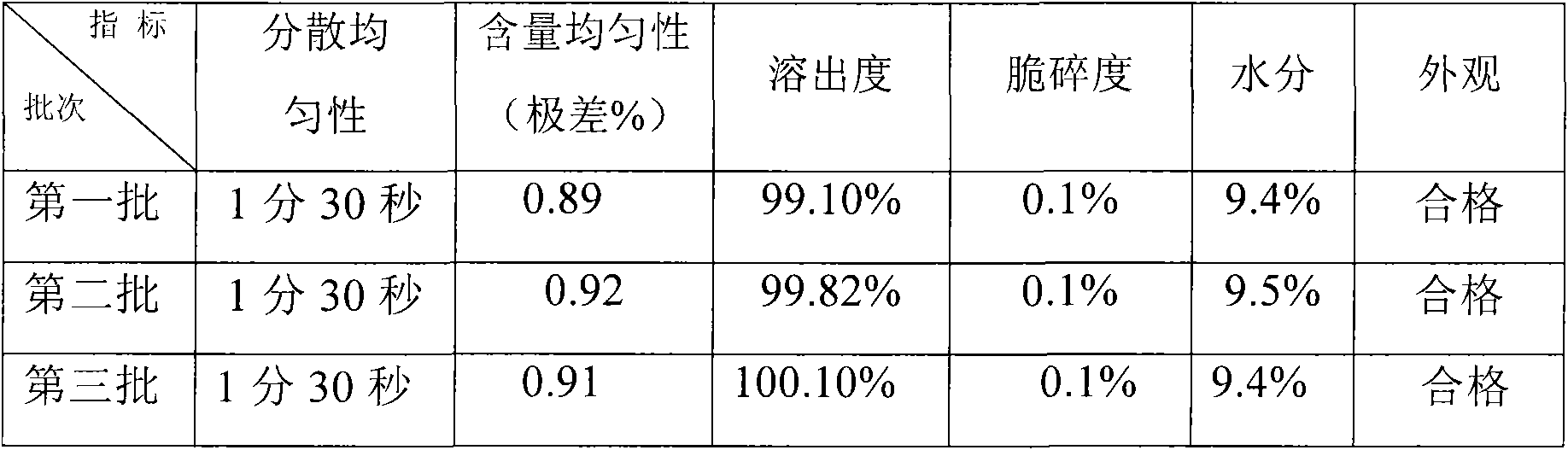

[0036] Example 1 Amoxicillin dispersible tablet of the present invention

[0037] The formula of amoxicillin dispersible tablets is as follows:

[0038] Amoxicillin Raw Powder 1500g

[0039] Microcrystalline Lactose (Cellactose-80) 400g

[0040] PVPP75g

[0042] Cyclamate 100g

[0043] Pineapple essence (solid) 50g

[0044] The above-mentioned amoxicillin raw powder is a product produced by North China Pharmaceutical Group Xiantai Co., Ltd. in accordance with the Pharmacopoeia; the above-mentioned microcrystalline lactose (Cellactose-80) is a product produced by German Meggle Company.

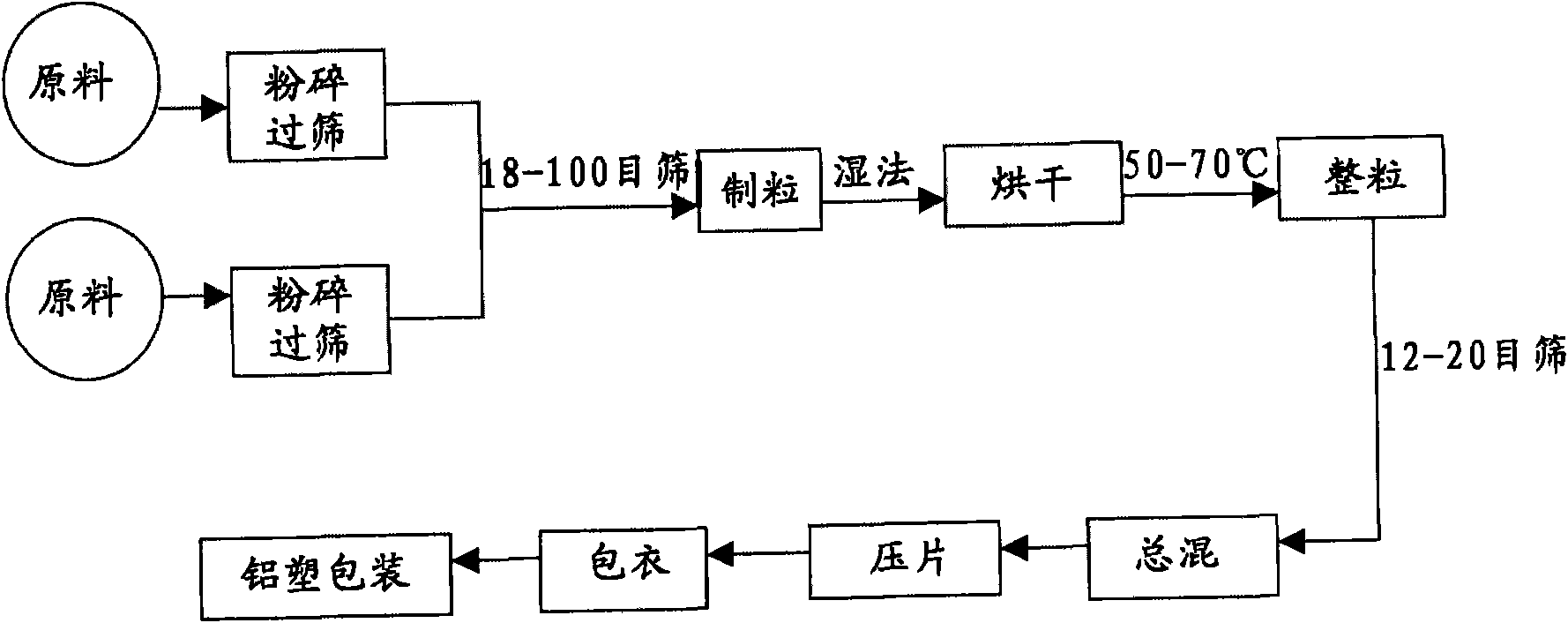

[0045] According to the following method, above-mentioned raw material is made into amoxicillin dispersible tablet:

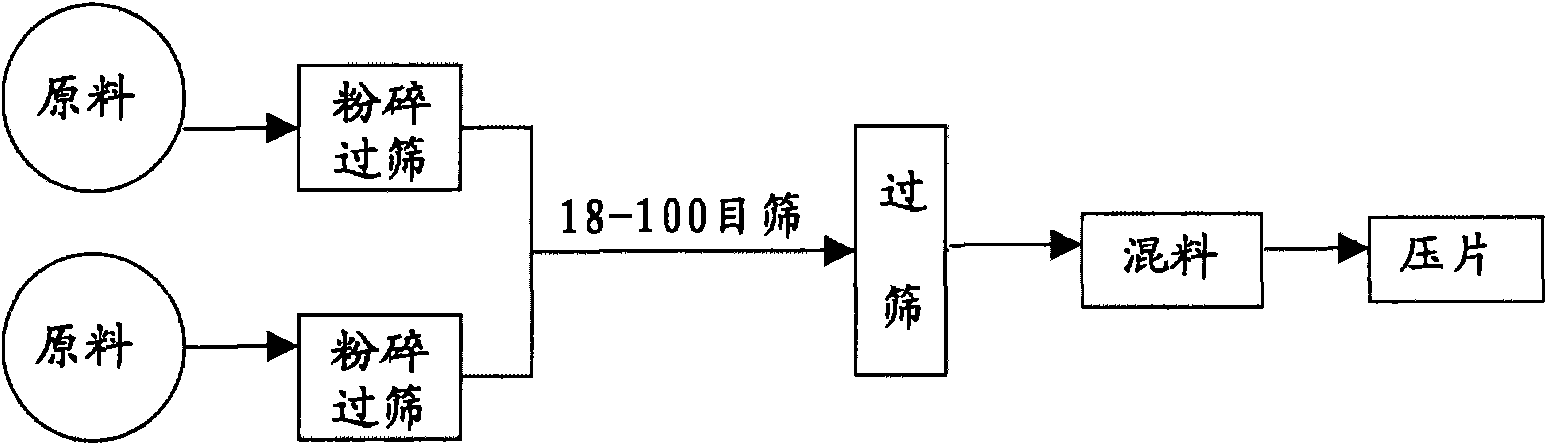

[0046] (1) Amoxicillin former drug is pulverized through a 30-mesh sieve;

[0047] (2) Mix all the above-mentioned auxiliary materials, pulverize, and pass through a 30-mesh sieve;

[0048] (3) Mix the products of the above two steps, cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com