Method for recycling sodium hypochlorite purifying liquid used for purifying acetylene gas

A technology of sodium hypochlorite and waste sodium hypochlorite, applied in chemical instruments and methods, purification/separation of hydrocarbons, water/sludge/sewage treatment, etc., can solve problems such as increased pressure on environmental protection, large amounts of water, and large consumption of water resources. To achieve the effect of reducing consumption and saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

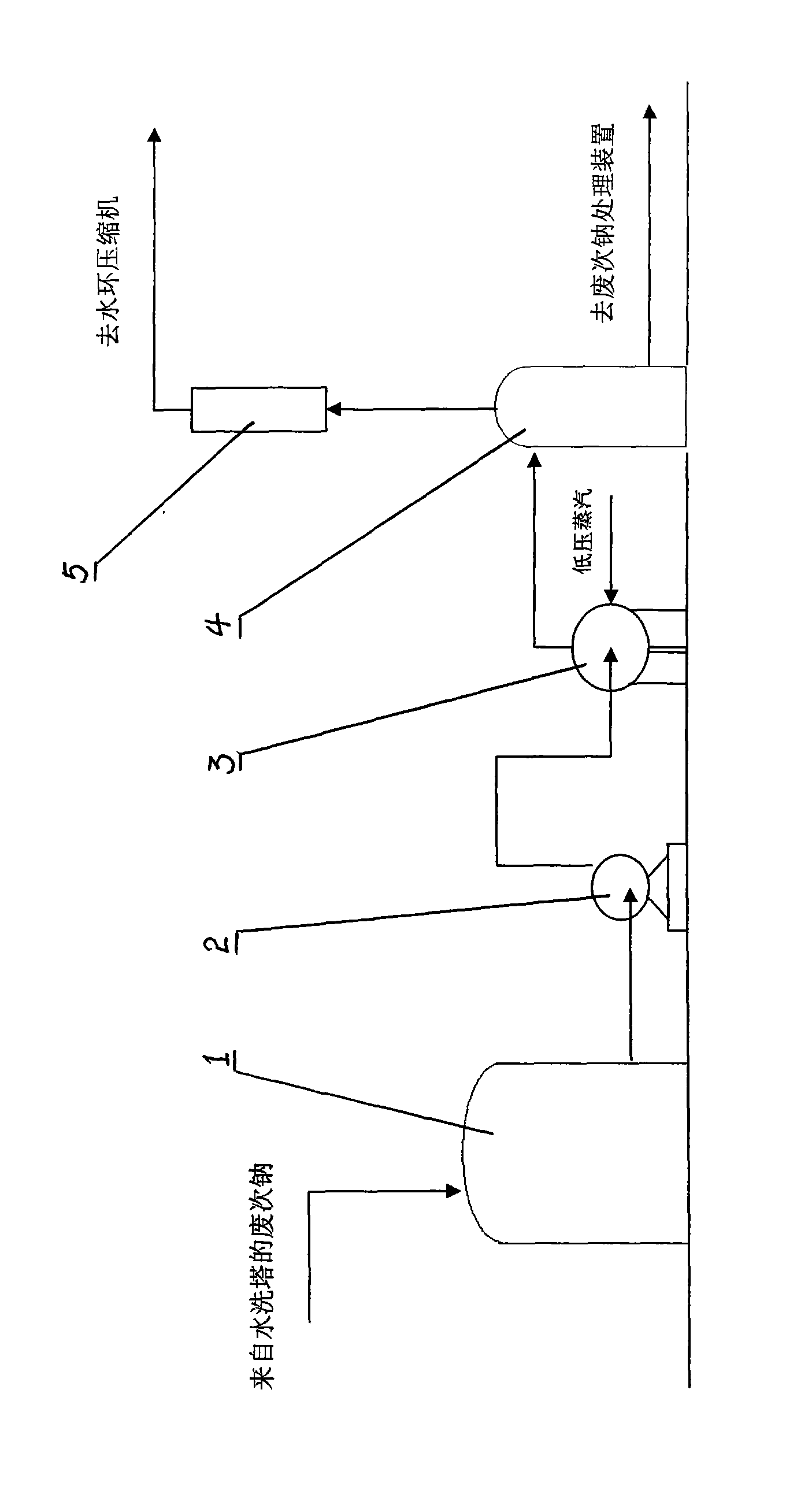

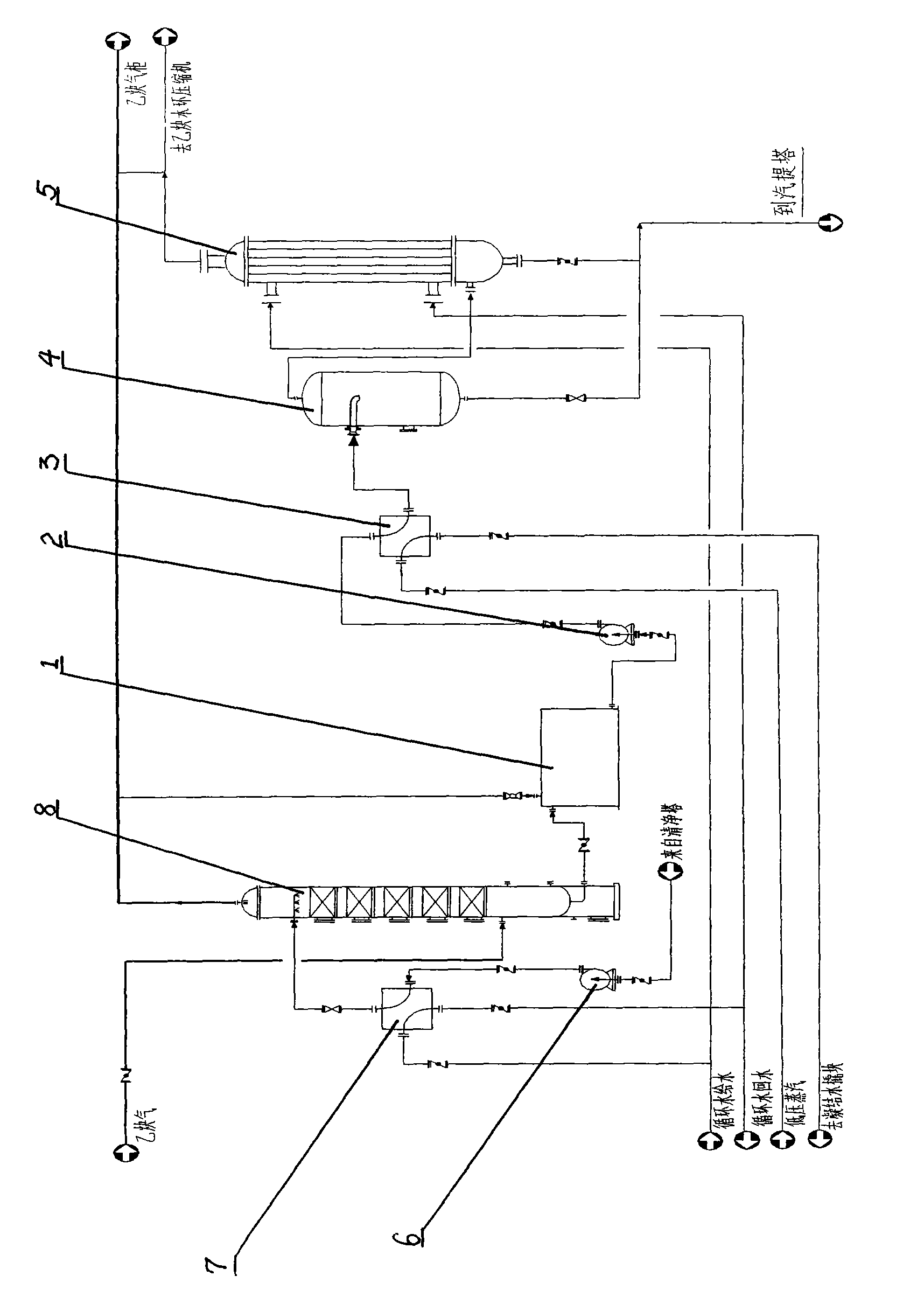

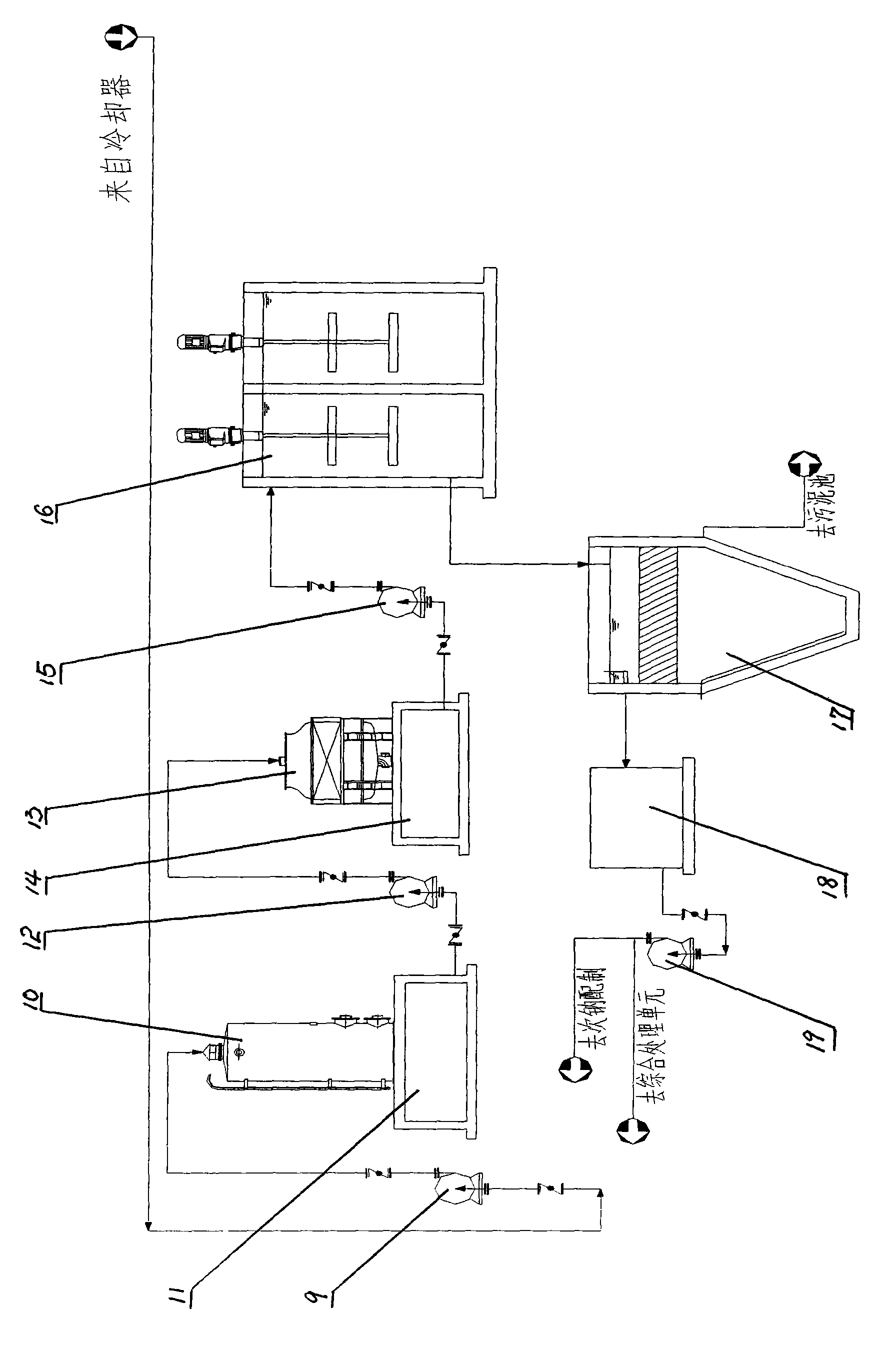

[0019] The pH value of the fresh sodium hypochlorite configured in the acetylene cleaning process is 7-8, and the available chlorine content is between 0.02-0.12%. Such as figure 1 , figure 2 As shown, 1-waste sodium hypochlorite liquid storage tank, 2-waste sodium hypochlorite lifting pump, 3-spiral plate heat exchanger, 4-gas-water separator, 5-acetylene cooler, 6-generator feed water pump, 7-spiral plate Heat exchanger, 8-water washing tower.

[0020] After the sodium hypochlorite cleans the acetylene gas in the cleaning tower, it is pumped out by the generator feed water pump 6, cooled by the spiral plate heat exchanger 7 at the outlet of the generator feed water pump, and enters the water washing tower 8 to spray and cool the acetylene gas , so far, the cleaning process of acetylene gas ends. Enter below the present invention to the technology that sodium hypochlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com