Parallel type energy feedback elevator system

An elevator system, energy feedback technology, applied in the AC network to reduce harmonics/ripples, reactive power compensation, harmonic reduction devices, etc., can solve the problem of affecting the module capacity specifications, increase the module capacity specifications, and the number of sensors. and other problems, to achieve the effect of excellent power factor and harmonic THD, reduce operation speed requirements, and suppress circulating current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

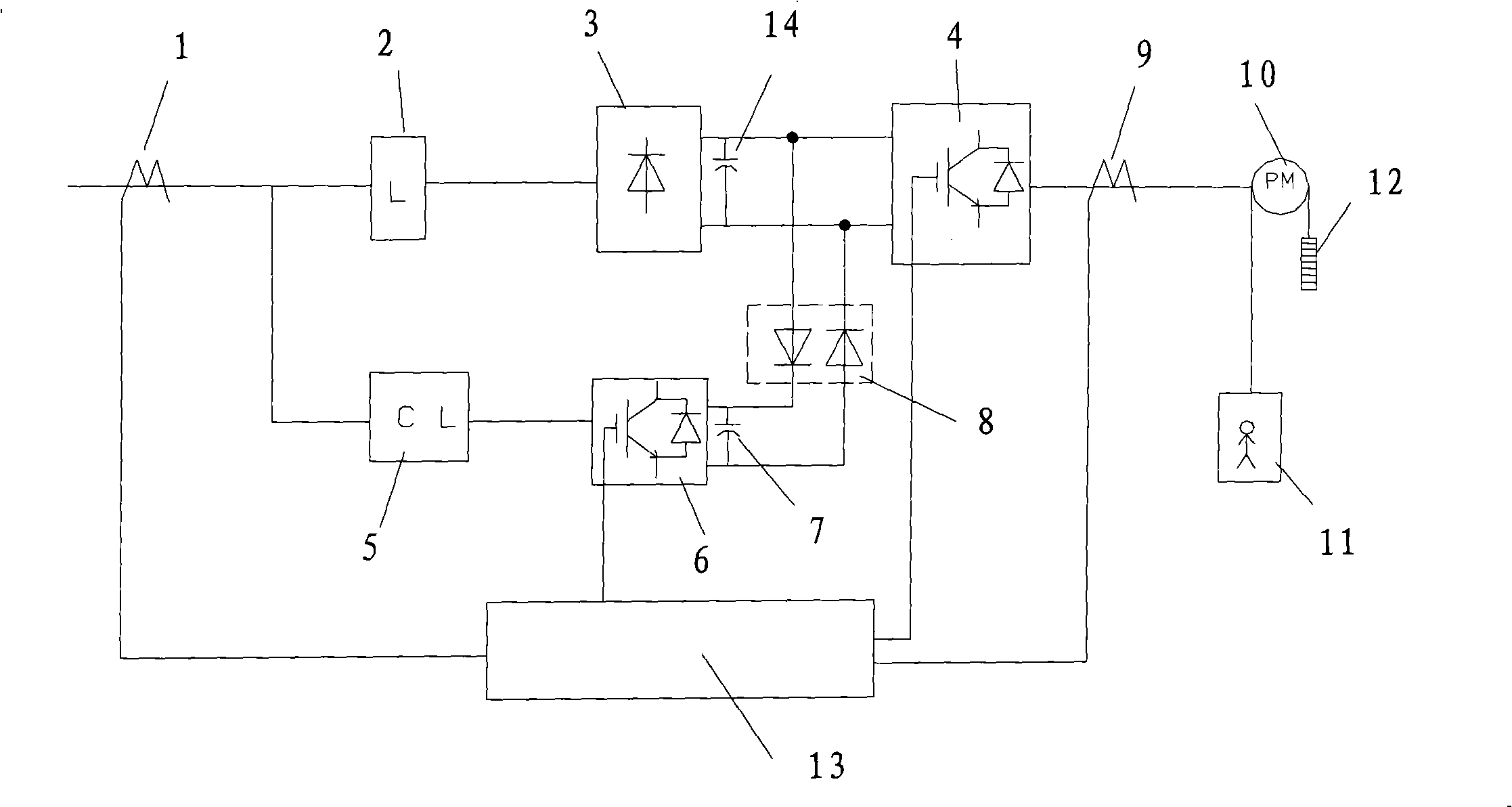

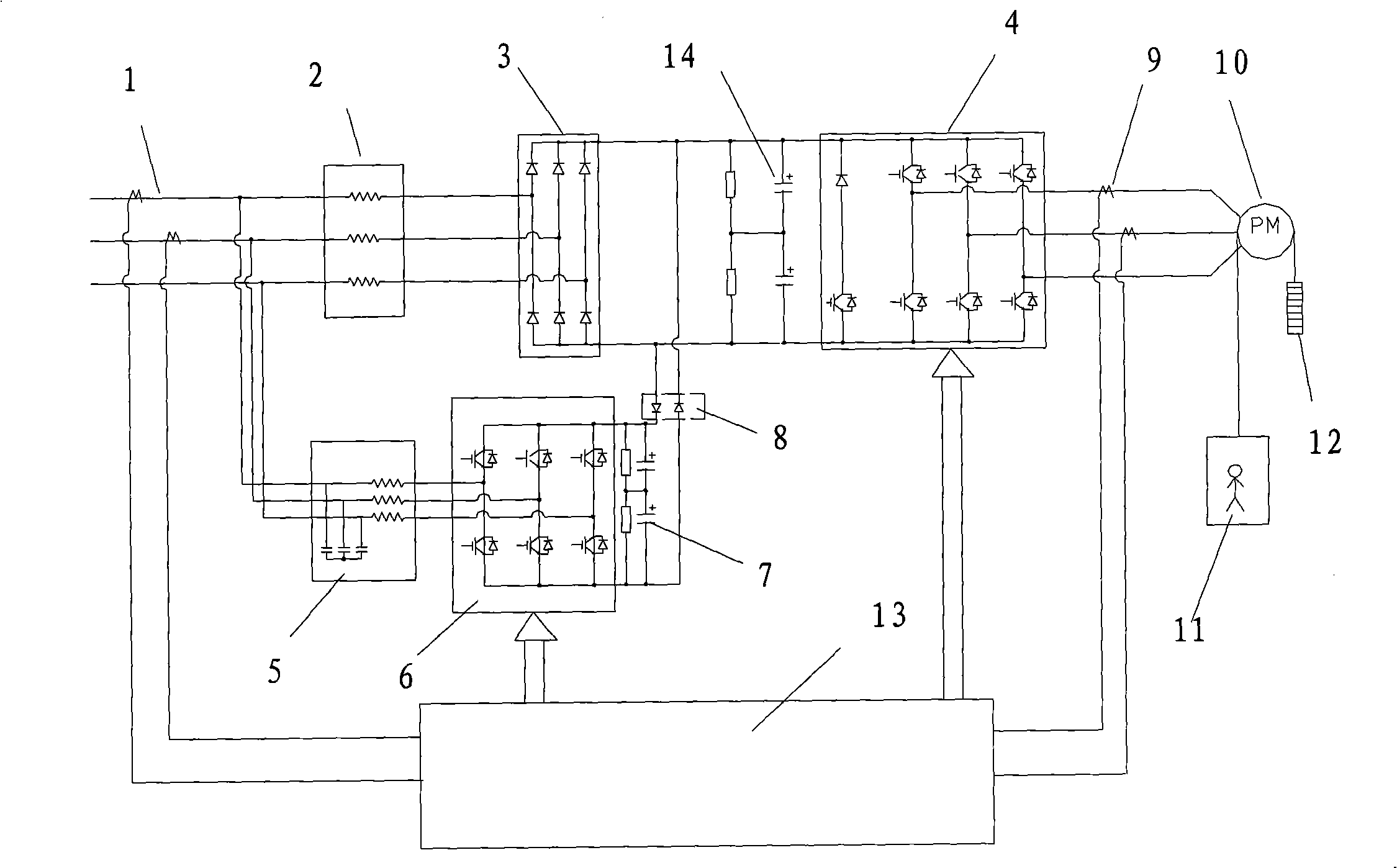

[0018] refer to figure 1 and 2 , a parallel energy feedback elevator system of the present invention is composed of a current sensor 1, a reactor 2, an uncontrollable rectification module 3, an inverter power module 4, a boost filter device 5, a PWM rectification module 6, a DC bus capacitor 7, It consists of a power diode module 8, a current sensor 9, a drive controller 13, and a DC bus capacitor 14. Among them, the reactor 2, the uncontrollable rectification module 3, the DC bus capacitor 14, and the inverter power module 4 form the elevator drive main circuit in the system of the present invention; the boost filter device 5, the PWM rectification module 6, the DC bus capacitor 7 and the power diode Module 8 constitutes the energy feedback device in the system of the present invention.

[0019] The DC side of the PWM rectification module 6 in the energy feedback device and the DC side of the uncontrollable rectification module 3 are connected by a power diode module 8 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com