Support board for perforation processing and method of perforation processing

A backing plate and substrate technology, which is applied in the field of perforation processing, can solve the problems of not being able to increase the number of printed wiring boards stacked, not being able to fully improve processing efficiency, and deteriorating the accuracy of perforation positions, achieving non-sticky and excellent anti-adhesion properties , Reduce drill bit breakage, excellent anti-adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

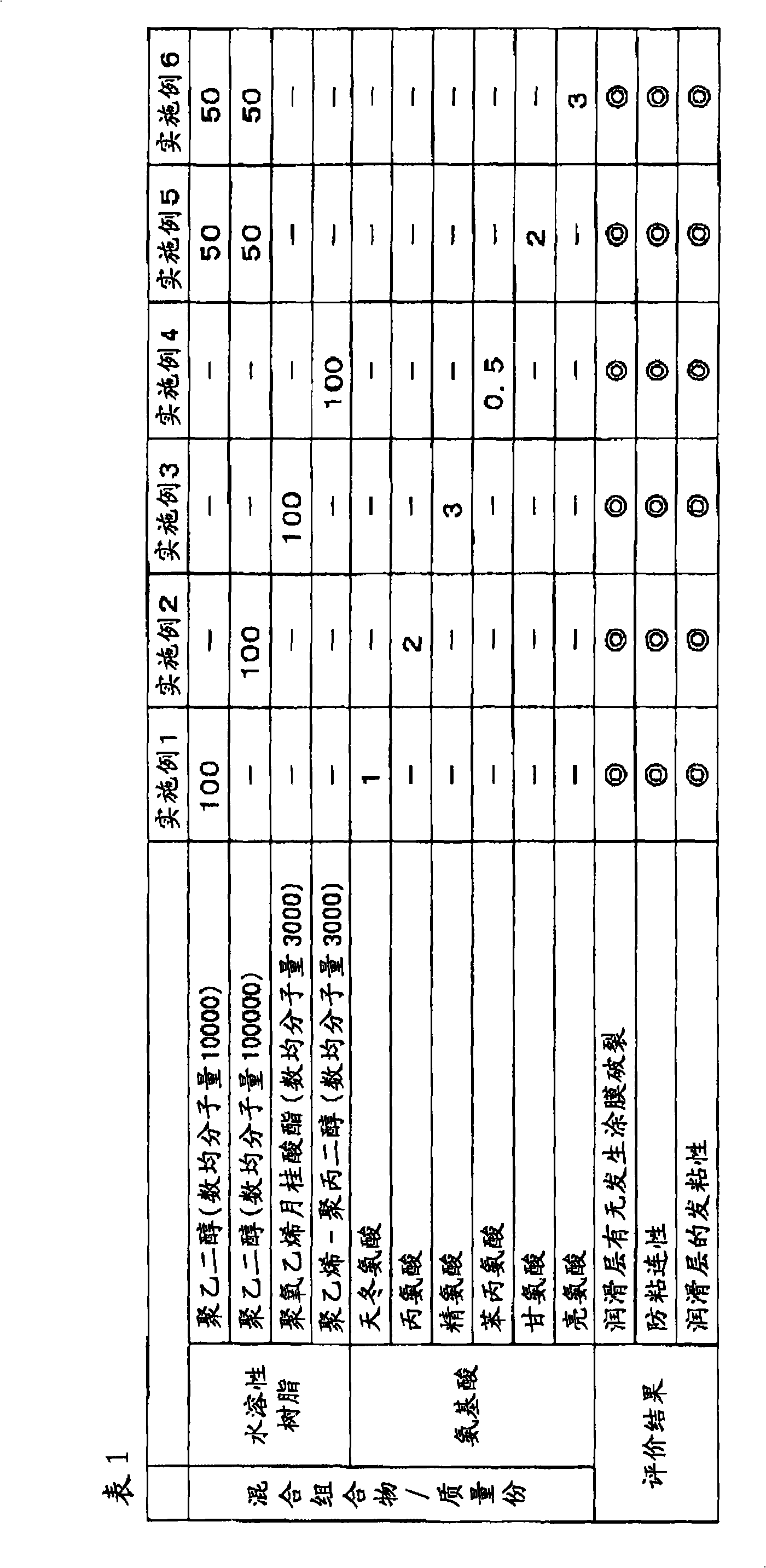

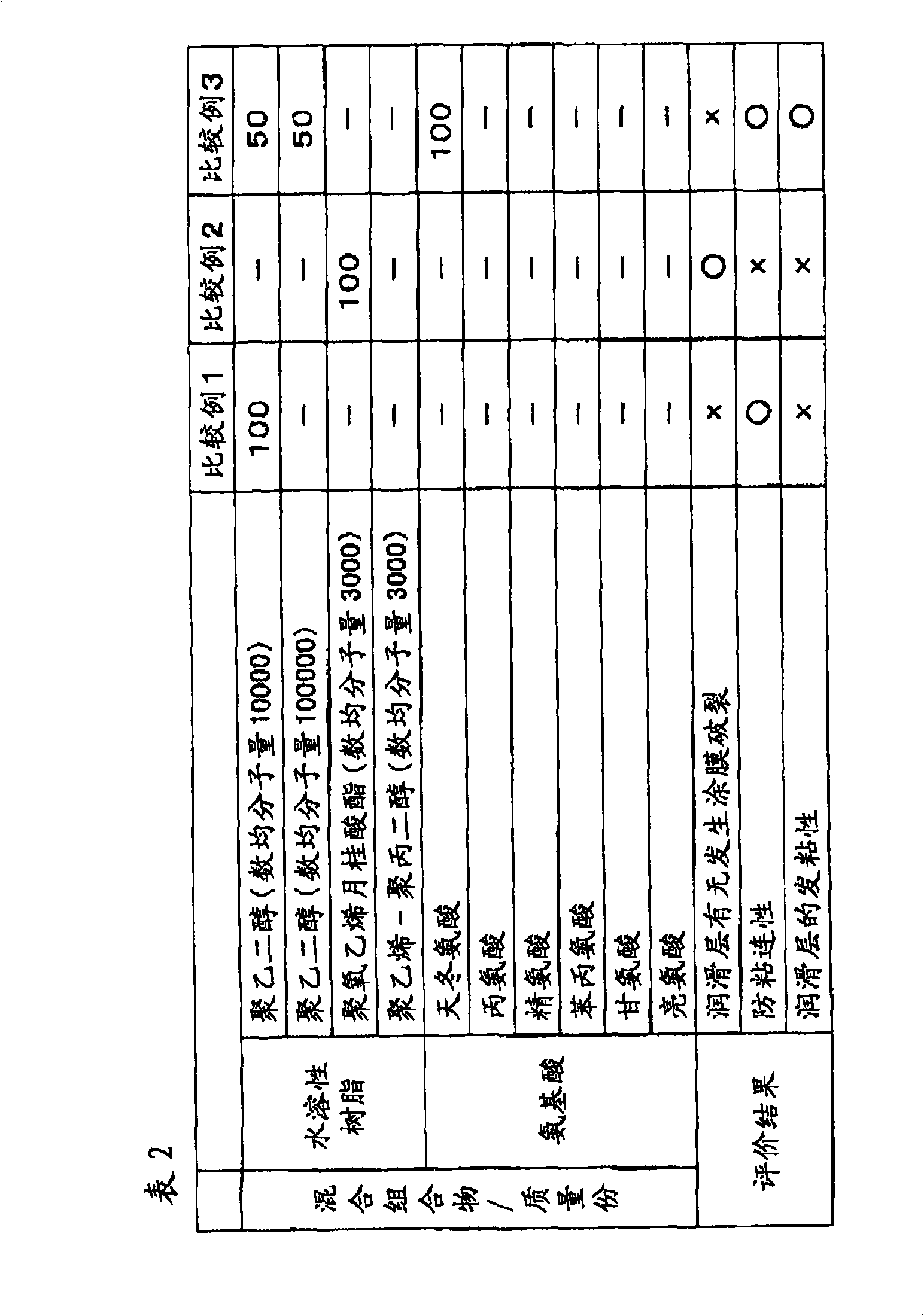

[0053] On one side of a substrate with a thickness of 100 μm formed by JIS A1N30-H18 material (this surface has been precoated), apply 100 parts by mass of polyethylene glycol with a number-average A mixed composition of aspartic acid was used to form a lubricating layer with a thickness of 30 μm, and a backing plate for punching was produced.

Embodiment 2~6

[0055] As a mixed composition, except having used the mixed composition which has the composition shown in Table 1, it carried out similarly to Example 1, and produced the backing board for punching processing.

[0056] In addition, the polyethylene glycol used in Examples 1, 2, 5, and 6, the polyoxyethylene laurate used in Example 3, and the polyethylene-polypropylene glycol used in Example 4 are all equivalent to "chosen One or more water-soluble resins selected from polyoxyethylene, polyoxyethylene-propylene copolymers, and their derivatives" water-soluble resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com