Inorganic fiber filtration material and preparation method and application thereof

A filter material and inorganic fiber technology are applied in the field of inorganic fiber filter material. The preparation field of the fiber material can solve the problems of the decline of smoking quality of flue-cured cigarettes, and achieve the effects of safe use, high adsorption effect and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

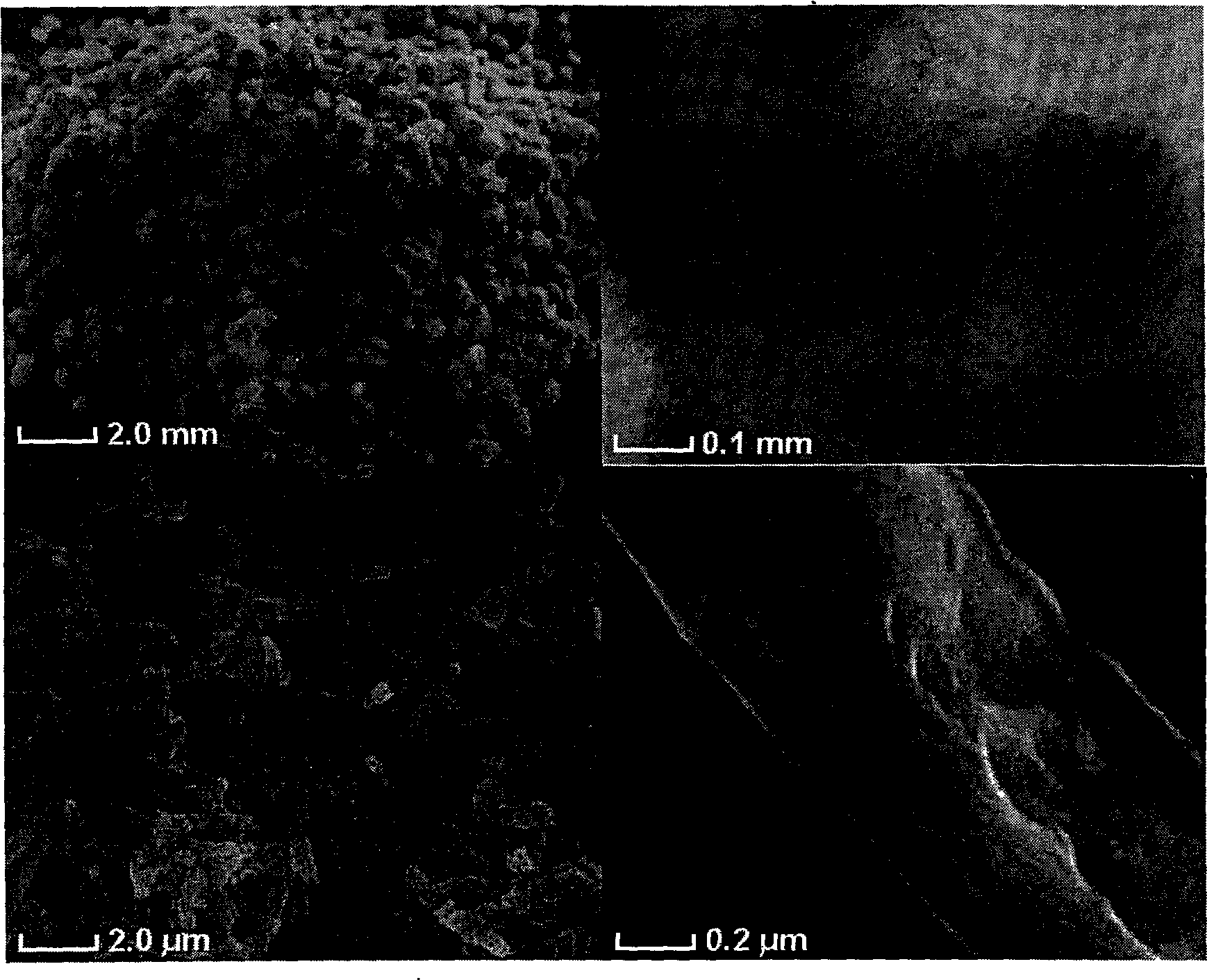

[0021] Preparation of inorganic fiber filter material. Weigh 0.5 parts of kaolin, 5 parts of limestone, 60 parts of quartz sand, 0.5 parts of borax, 0.2 parts of fluorite, 2 parts of nitrate and 1 part of titanium dioxide. Mix the raw materials evenly, crush the mixture to 100 mesh, and then heat it in a high-temperature furnace to 1100°C to melt. The molten material is drawn into ultra-fine wires with a diameter of 0.2 μm and a length of 2 mm through a spinning device, and the ultra-fine wires are softened. Rolled into particles with a diameter of 0.5mm, which is the required inorganic fiber filter material.

Embodiment 2

[0023] Preparation of inorganic fiber filter material. Weigh 2.5 parts of kaolin, 10 parts of limestone, 75 parts of quartz sand, 1 part of borax, 0.6 parts of fluorite, 4 parts of nitrate and 1.5 parts of alumina. Mix the raw materials evenly, crush the mixture to 250 mesh, and then heat it in a high-temperature furnace to 1300°C to melt. The molten material is drawn into ultra-fine wires with a diameter of 0.5 μm and a length of 3.5 mm through a spinning equipment, and the ultra-fine wires are softened. After rolling, it is made into particles with a diameter of 0.8mm, which is the required inorganic fiber filter material.

Embodiment 3

[0025] Preparation of inorganic fiber filter material. Weigh 5 parts of kaolin, 15 parts of limestone, 90 parts of quartz sand, 2 parts of borax, 1 part of fluorite, 6 parts of nitrate and 2 parts of magnesium silicate. Mix the raw materials evenly, crush the mixture to 400 mesh, and then heat it in a high-temperature furnace to 1500°C to melt. The molten material is drawn into ultra-fine wires with a diameter of 0.8 μm and a length of 5 mm through a spinning device, and the ultra-fine wires are softened. Rolled into particles with a diameter of 1.0mm, which is the required inorganic fiber filter material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air permeability | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com