Method and device for treating organic waste gas by combining photocatalysis and microorganisms and application thereof

An organic waste gas, photocatalytic reactor technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problem that the residence time is not long enough, the photocatalytic reactant cannot oxidize organic matter in the waste gas, and the photocatalytic efficiency Reduce and other problems to achieve the effect of reducing shielding and poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

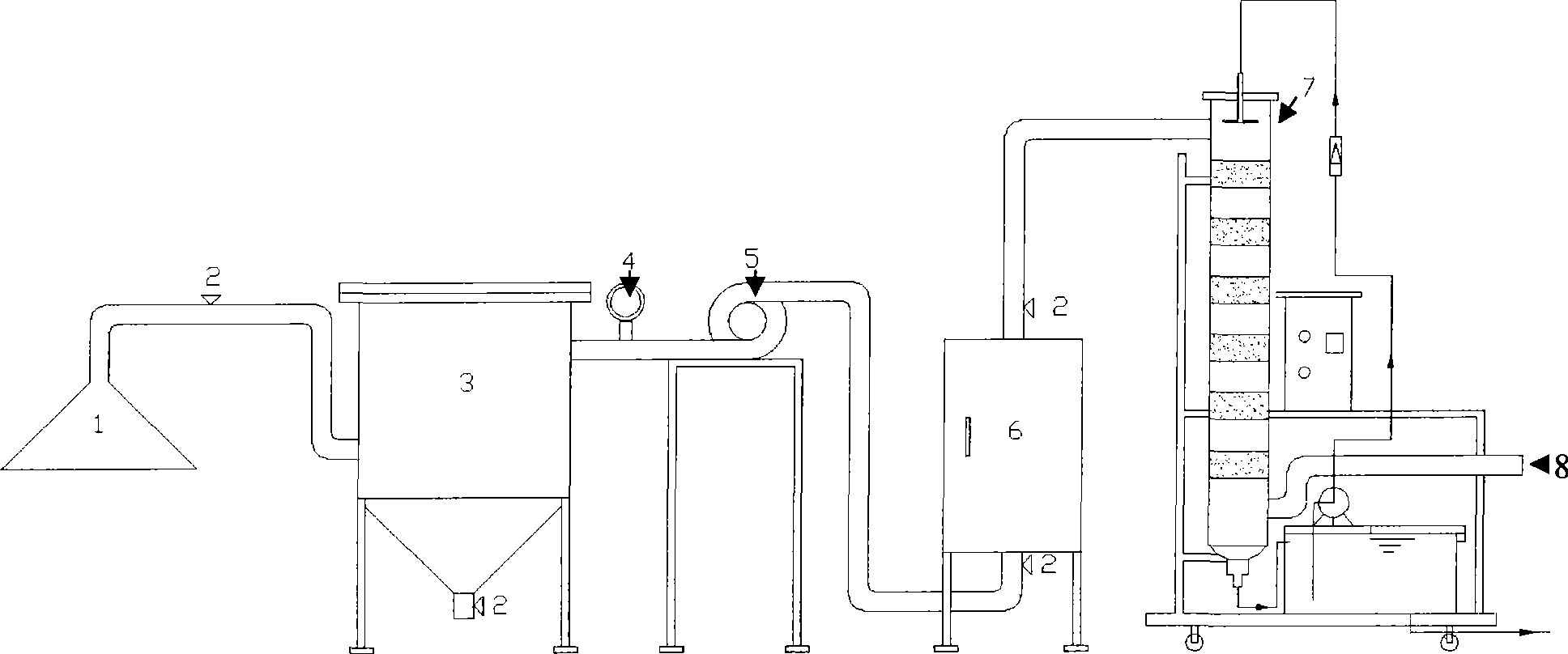

[0035] (1) Equipment for the combined use of photocatalysis and microorganisms to treat organic waste gas: such as figure 1 As shown, the equipment for the photocatalytic and microbial combined method is passed through the gas collection hood 1, the valve 2, the bag filter 3, the flow-through photocatalytic reactor 6 (see ZL200420088717.8 for detailed structure) and the biological trickling filter tower 7. The pipelines are connected in sequence, wherein an anemometer 4 and a fan 5 are connected in sequence between the bag filter 3 and the flow-through photocatalytic reactor 6 . The photocatalyst fixed bed of described flow-through photocatalytic reactor 6 is 5 layers, and the size of fixed bed is 500 * 450mm, nano ZnO-SnO 2 The composite oxide photocatalyst is supported on the activated carbon fiber filaments. The biological trickling filter tower 7 is a 2L stainless steel tank with an inner diameter of 400 mm. The top is provided with a waste gas inlet, an air inlet control...

Embodiment 2

[0043] The difference between this embodiment and the equipment operated in embodiment 1 is that the photocatalyst of this embodiment is nano TiO 2 catalyst of light. The operating conditions of the equipment are the same as those in Example 1. In the initial stage of organic waste gas, the removal efficiency of total benzene series after photocatalysis is 89.9%, and the total treatment efficiency after microbial degradation is 98%. After one month of operation of the photocatalytic and microbial combined method, the removal efficiency of the total benzene series after photocatalysis is 89.1%, and the total treatment efficiency after microbial degradation is 99.9%.

Embodiment 3

[0045] The equipment for the photocatalytic and microbial combined method for treating organic waste gas and the preparation of the packing layer of the biological trickling filter tower are the same as in Example 1.

[0046] After the equipment of the photocatalysis and microorganism combination method was operated for one month, the test of the influence of the change of the flow rate on the photocatalysis and microorganism combination method equipment was carried out. Regulate the flow velocity of the organic waste gas entering the flow-through photocatalytic reactor 6 through the fan, and the flow velocity is 300m 3 / h, then, organic waste gas at 300m 3 / h enters the biological trickling filter tower 7, and the collected samples are analyzed. After photocatalysis, the removal efficiency of total benzene series is 75%, and after microbial degradation, the total treatment efficiency is 98.1%. Reduce the flow velocity of the organic waste gas into the flow-through photocatal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com