Noble metal/zinc oxide compound nano-hollow sphere and preparation method thereof

A technology of zinc oxide and precious metals, applied in the direction of coating, etc., can solve the problems of energy consumption and time-consuming products, environmental pollution, large size of zinc oxide hollow spheres, etc., and achieve the effect of uniform size and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

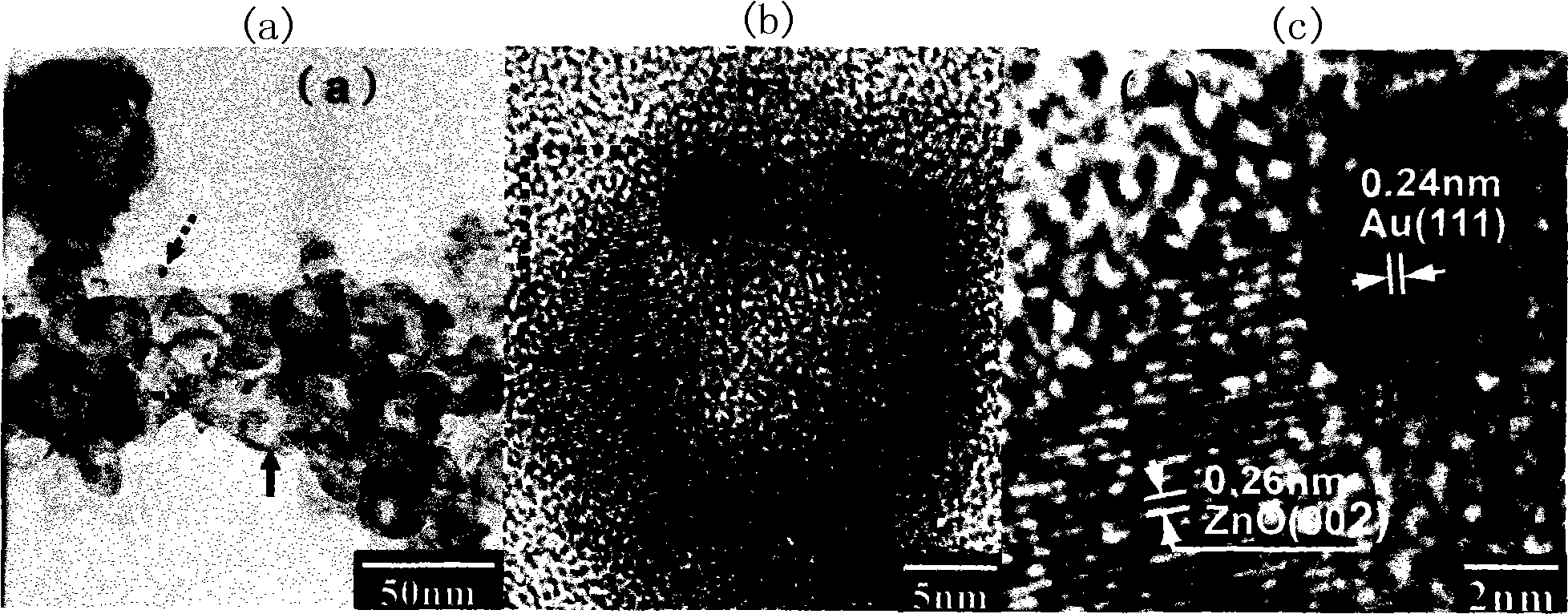

Embodiment 1

[0018] Embodiment 1: complete preparation successively according to the following steps: the first step, earlier sodium lauryl sulfate is mixed with water, obtains concentration and is the sodium lauryl sulfate solution of 0.01M, then zinc flakes are placed under stirring In sodium lauryl sulfate solution; Wherein, water is deionized water, and the purity of zinc sheet is 99.9%. The second step is to irradiate the zinc sheet with a laser with a wavelength of 1064nm, a power of 100mJ / pulse, a frequency of 5Hz, and a pulse width of 15ns for 50min to obtain a zinc / zinc oxide colloid; wherein, the diameter of the laser spot is 2.5mm, and the emission wavelength is The laser of 1064nm laser is Nd:YAG solid-state laser. The 3rd step, in the zinc / zinc oxide colloid under stirring earlier, dropwise concentration is the noble metal acid solution of 1mM to obtain product, wherein, the volume ratio of zinc / zinc oxide colloid and noble metal acid solution is 20:1.2, noble metal acid solutio...

Embodiment 2

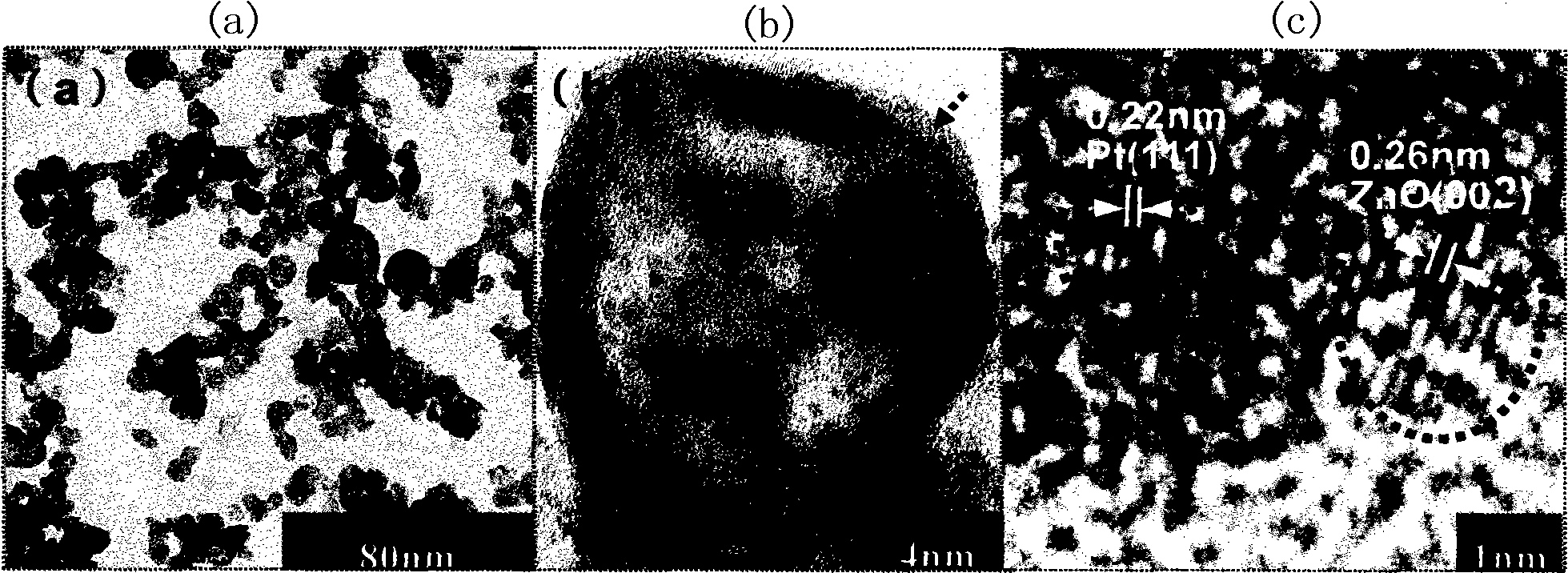

[0019] Embodiment 2: complete preparation successively according to the following steps: the first step, earlier sodium lauryl sulfate is mixed with water, obtains concentration and is the sodium lauryl sulfate solution of 0.03M, then zinc sheet is placed under stirring Sodium lauryl sulfate solution; wherein, the water is distilled water, and the purity of the zinc flakes is 99.99%. The second step is to irradiate the zinc sheet with a laser with a wavelength of 1064nm, a power of 80mJ / pulse, a frequency of 8Hz, and a pulse width of 13ns for 55min to obtain zinc / zinc oxide colloid; wherein, the diameter of the laser spot is 2.3mm, and the emission wavelength is The laser of 1064nm laser is Nd:YAG solid-state laser. The 3rd step, in the zinc / zinc oxide colloid under stirring earlier, dropwise concentration is the noble metal acid solution of 2mM to obtain product, wherein, the volume ratio of zinc / zinc oxide colloid and noble metal acid solution is 20:1.1, noble metal acid sol...

Embodiment 3

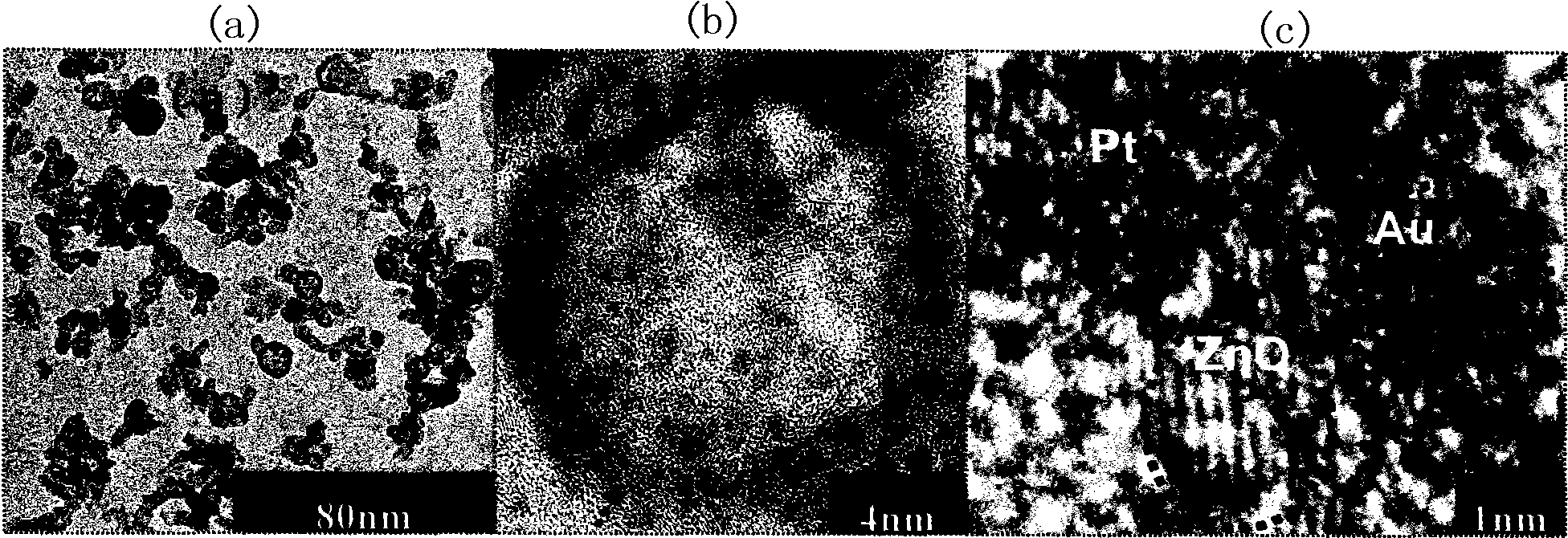

[0020] Embodiment 3: complete preparation successively according to the following steps: the first step, earlier sodium lauryl sulfate is mixed with water, obtains concentration and is the sodium lauryl sulfate solution of 0.05M, then zinc flakes are placed under stirring In sodium lauryl sulfate solution; Wherein, water is deionized water, and the purity of zinc sheet is 99.9%. The second step is to irradiate the zinc sheet with a laser with a wavelength of 1064nm, a power of 70mJ / pulse, a frequency of 10Hz, and a pulse width of 10ns for 60 minutes to obtain a zinc / zinc oxide colloid; wherein, the diameter of the laser spot is 2mm, and the emission wavelength is 1064nm The laser of the laser is a Nd:YAG solid-state laser. The 3rd step, in the zinc / zinc oxide colloid under stirring earlier, dropwise concentration is the noble metal acid solution of 3mM to obtain product, wherein, the volume ratio of zinc / zinc oxide colloid and noble metal acid solution is 20:1, and noble metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com