Metal-organic framework material with nano pores and preparation method and application thereof

An organic framework and nanopore technology, applied in organic chemistry, zinc-organic compounds, chemical instruments and methods, etc., can solve the problems of high production cost, low production efficiency, and high production equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

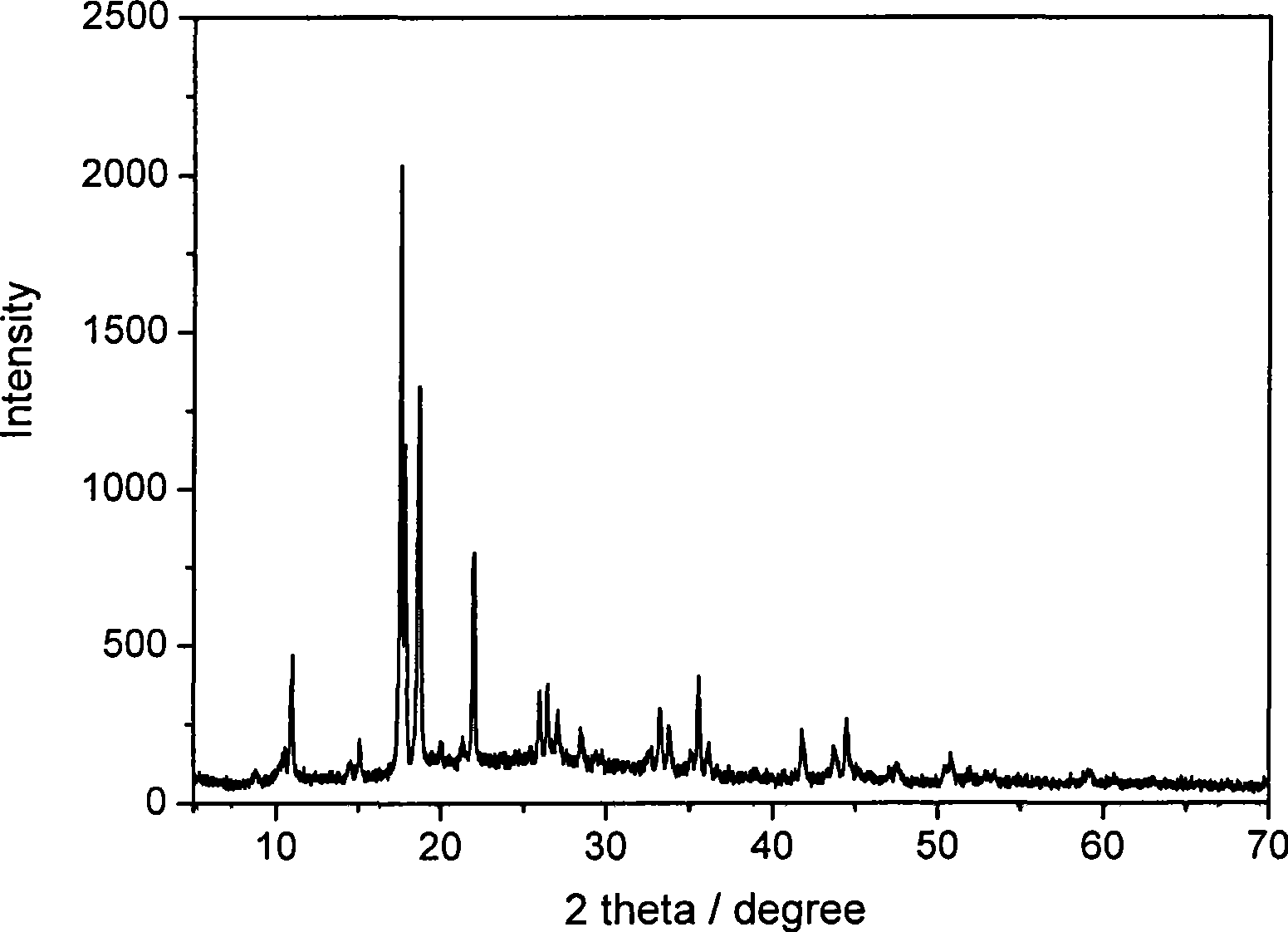

Embodiment 1

[0038]Weigh 0.181 g (0.83 mmol) of zinc nitrate dihydrate and dissolve it in 5 mL of water as reaction component A. Weigh 0.105 g (0.5 mmol) of 1,3,5-benzenetricarboxylic acid and dissolve it in 2 mL of ethanol as reaction component B. Add reaction component A to reaction component B, or add reaction component B to reaction component A, put into a 20mL test tube, and then put the test tube containing the reaction mixture into the ultrasonic generator filled with water (JL-60DTH, Shanghai J&L Ultrasonic Instrument Co., Ltd.), the ultrasonic frequency is 40KHz, and the output power is 60W. Turn on the ultrasonic switch, react the reaction container under ultrasonic radiation for 5 minutes, and stop the reaction. The resulting reaction mixture was suction-filtered, washed with 50 mL of water, and then washed with 10 mL of ethanol for 3 times, and then the product was put into a vacuum drying oven and dried at 70 degrees Celsius for 4 hours under the condition of a vacuum of 0.00...

Embodiment 2

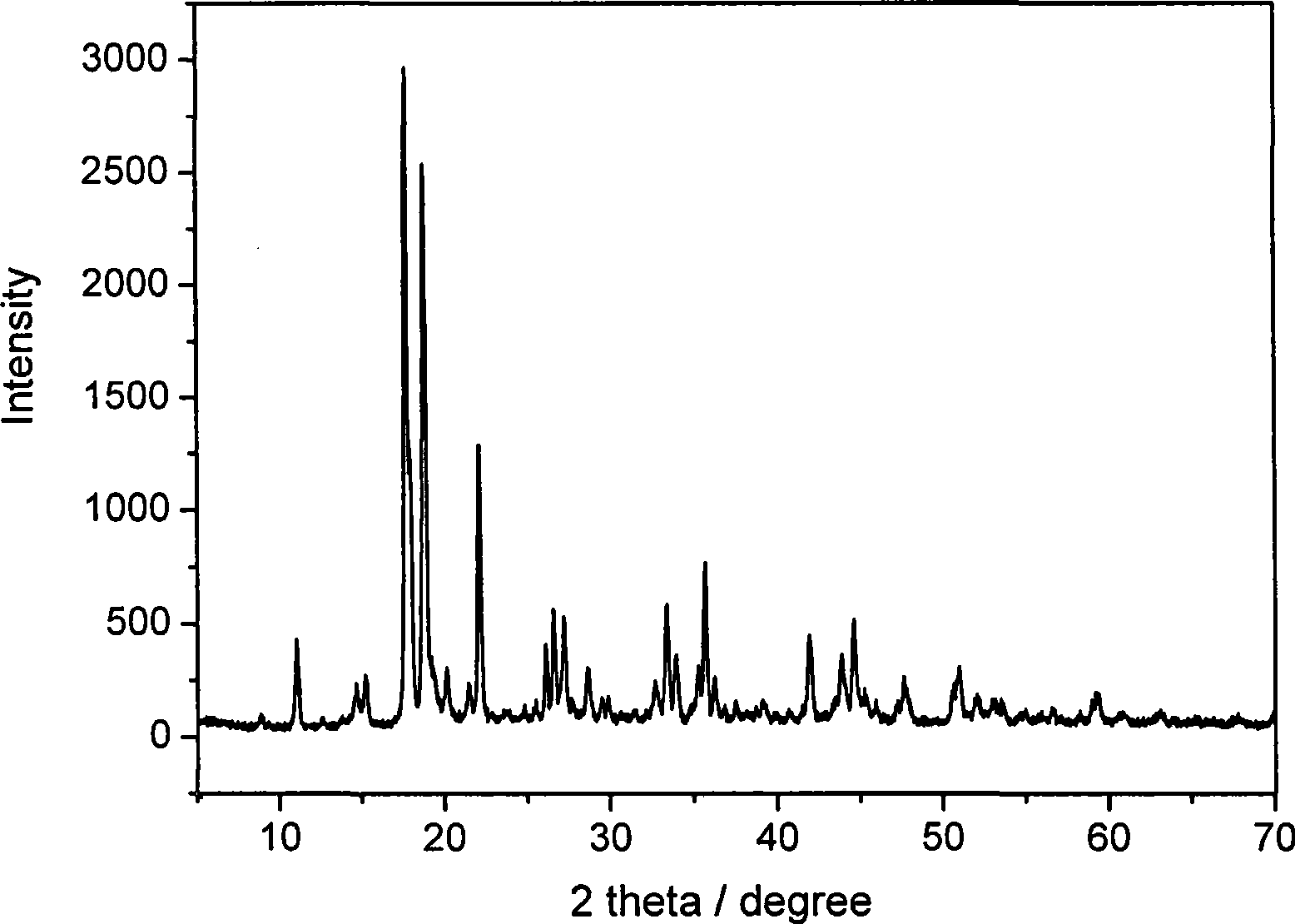

[0041] Weigh 0.181 g (0.83 mmol) of zinc nitrate dihydrate and dissolve it in 5 mL of water as reaction component A. Weigh 0.105 g (0.5 mmol) of 1,3,5-benzenetricarboxylic acid and dissolve it in 2 mL of ethanol as reaction component B. Add reaction component A to reaction component B, or add reaction component B to reaction component A, put into a 20mL test tube, and then put the test tube containing the reaction mixture into the ultrasonic generator filled with water (JL-60DTH, Shanghai J&L Ultrasonic Instrument Co., Ltd.), the ultrasonic frequency is 40KHz, and the output power is 60W. Turn on the ultrasonic switch, react the reaction container under ultrasonic radiation for 30 minutes, and stop the reaction. The resulting reaction mixture was suction-filtered, washed with 50 mL of water, and then washed with 10 mL of ethanol for 3 times, and then the product was put into a vacuum drying oven and dried at 70 degrees Celsius for 4 hours under the condition of a vacuum of 0....

Embodiment 3

[0044] Coat a certain amount of the metal-organic framework material synthesized in Example 2 on a glass plate, fix it in a quartz cuvette, add 2mL of acetonitrile as a solvent in the cuvette, and measure it at an excitation wavelength of 327nm and room temperature. After adding a certain volume of ethylamine with a micro-syringe each time, measure its fluorescence intensity under the same conditions. The fluorescence intensity of the material test piece varies with the addition of ethylamine as follows: Figure 5 shown.

[0045] As can be seen from the figure, as the amount of ethylamine increases, the fluorescence intensity of the maximum absorption peak of the metal-organic framework material test piece synthesized in Example 2 gradually decreases, and its quantitative relationship is as follows: Figure 5 shown.

[0046] In order to investigate the impact caused by other organic amines on the determination of ethylamine, the same method as in this embodiment has been used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com