Hollow fiber concrete sandwich stalk compression brick building block

A fiber reinforced concrete and hollow fiber technology, which is applied in sustainable waste treatment, solid waste management, application, etc., can solve the problems of destroying the ecological environment, air pollution, low utilization rate of development, etc., and achieves reduced heat transfer coefficient and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

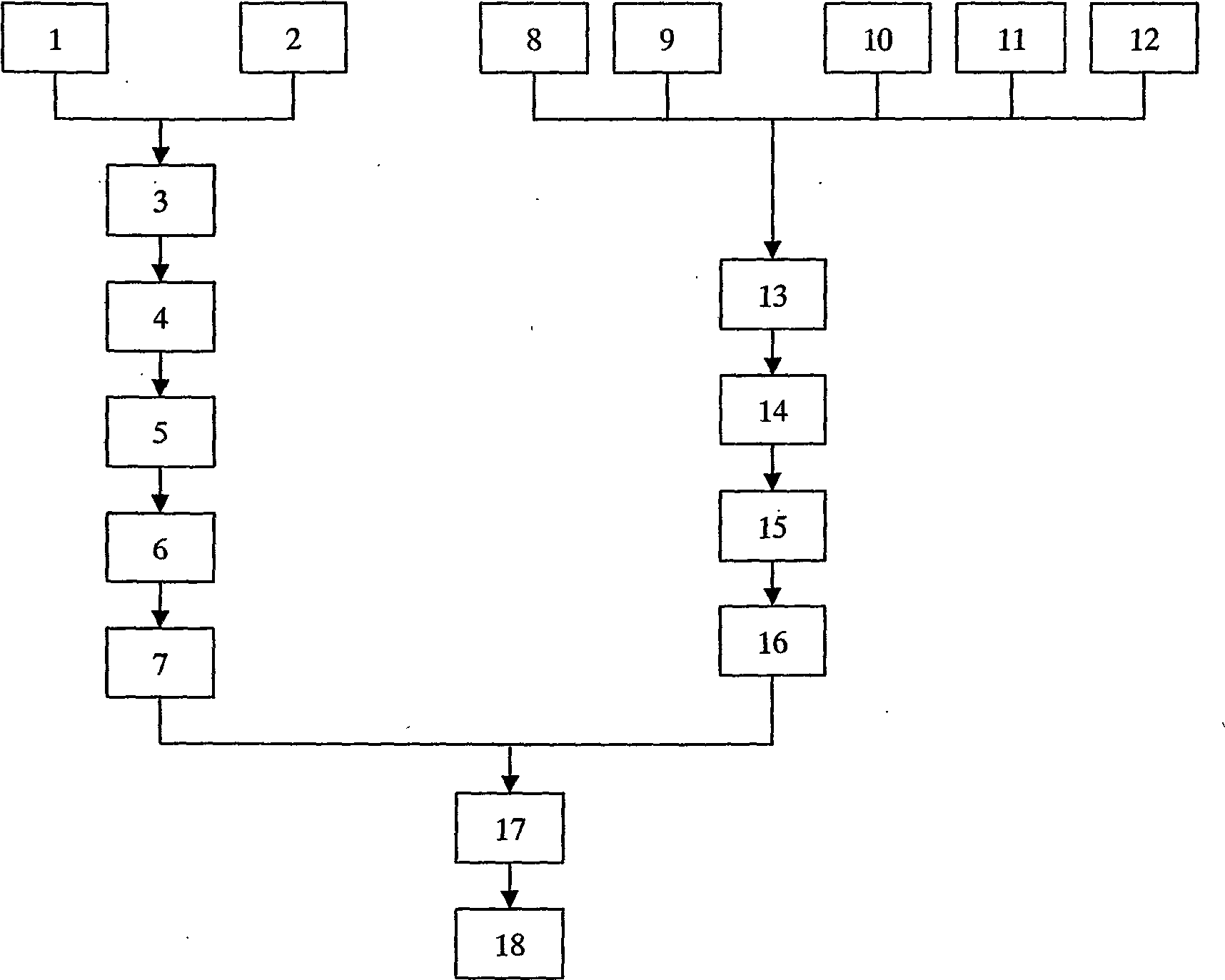

[0015] The processing process of the new wall material is as follows:

[0016] The production of compressed straw bricks is based on the above-mentioned material ratio. Prepare lime slurry (1) and water (2), mix them thoroughly (3), then mix them with wheat straw (4), and then put them into the mold (5), cold press molding (6), its size is determined according to the requirements of hollow fiber concrete blocks.

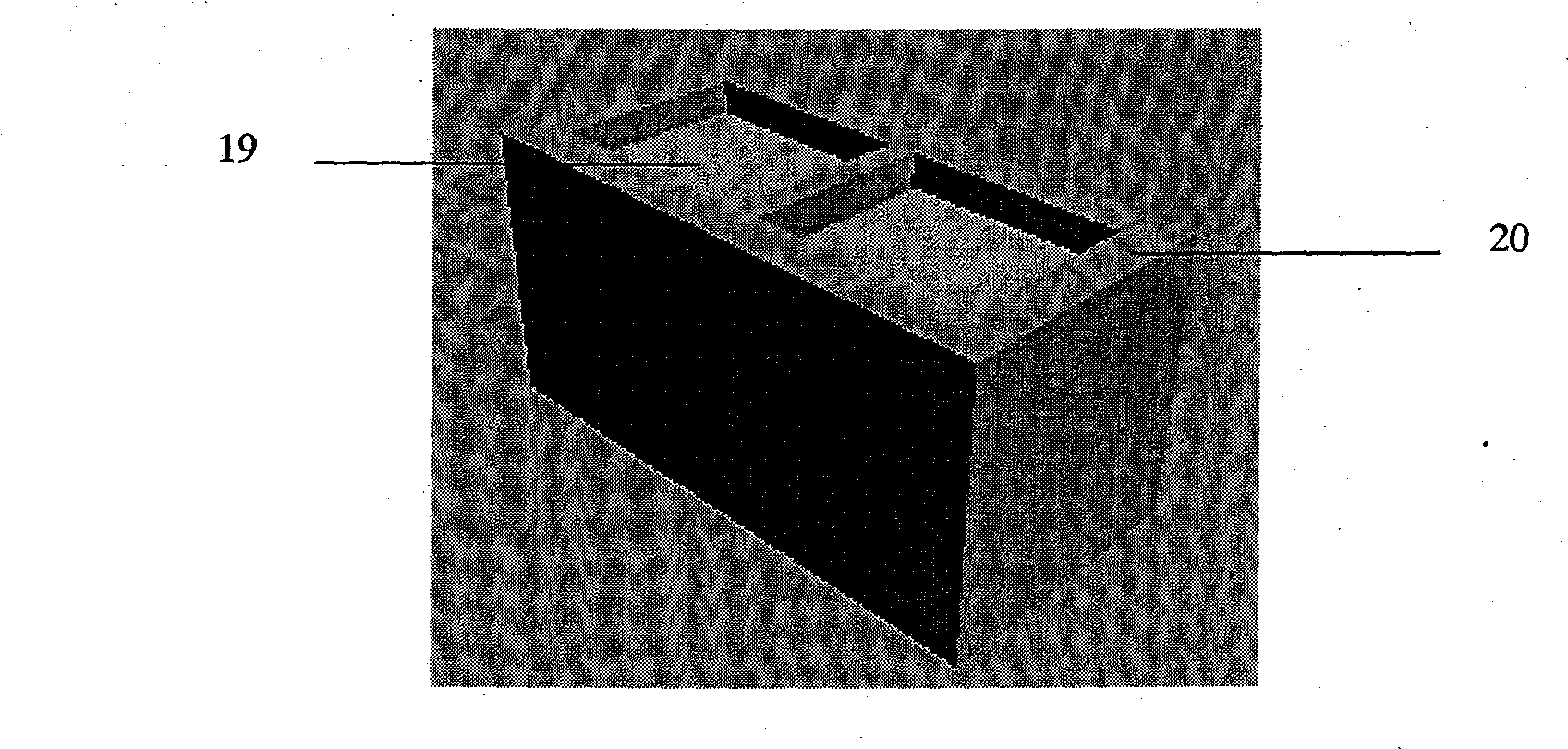

[0017] The hollow fiber concrete block is made according to the above-mentioned material ratio. First, mix cement (8), polypropylene fiber (9), crushed stone (10), sand (11) and fly ash (12) thoroughly (13). ), then add water and stir evenly (14), then put it into the mold (15), remove the mold and maintain (16), (17) to form a complete product, save (18), fill the molded straw compression brick (19) Into the hollow fiber concrete block (20).

[0018] The finished product of the invention is stored in a room temperature environment. The invention is suitable for mass pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com