Squirrel-cage elastic support and design method thereof

An elastic support, squirrel cage technology, applied in the rigid bracket of bearing components, calculation, mechanical equipment, etc., can solve the problems of uneven rigidity along the circumference, stress concentration of cage bars, etc., to improve the uneven rigidity , reduce stress concentration, improve the effect of stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

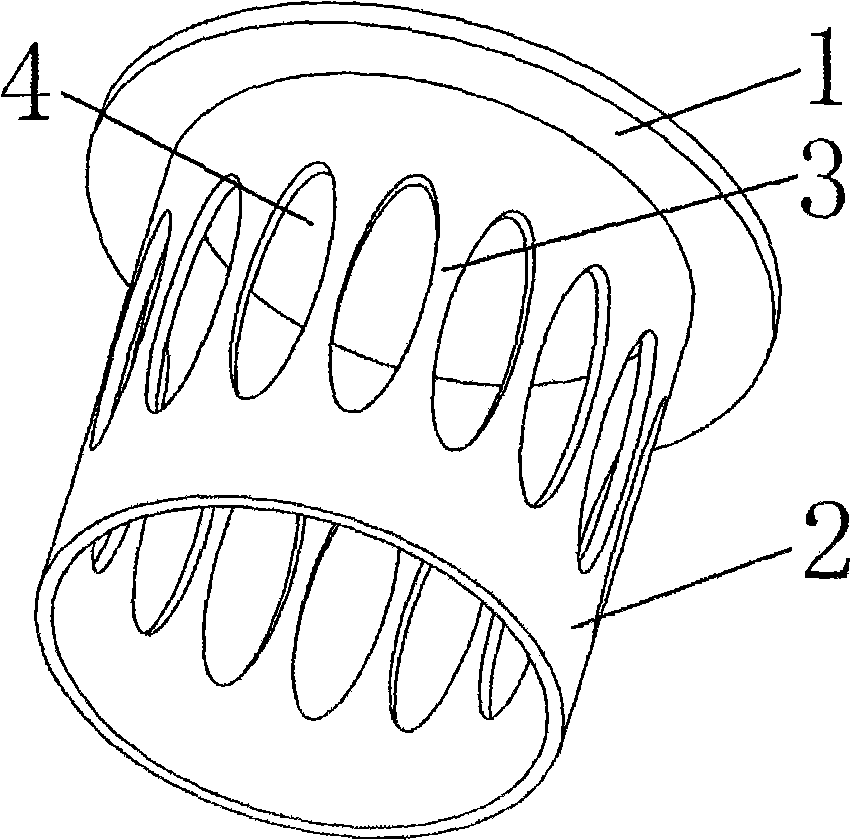

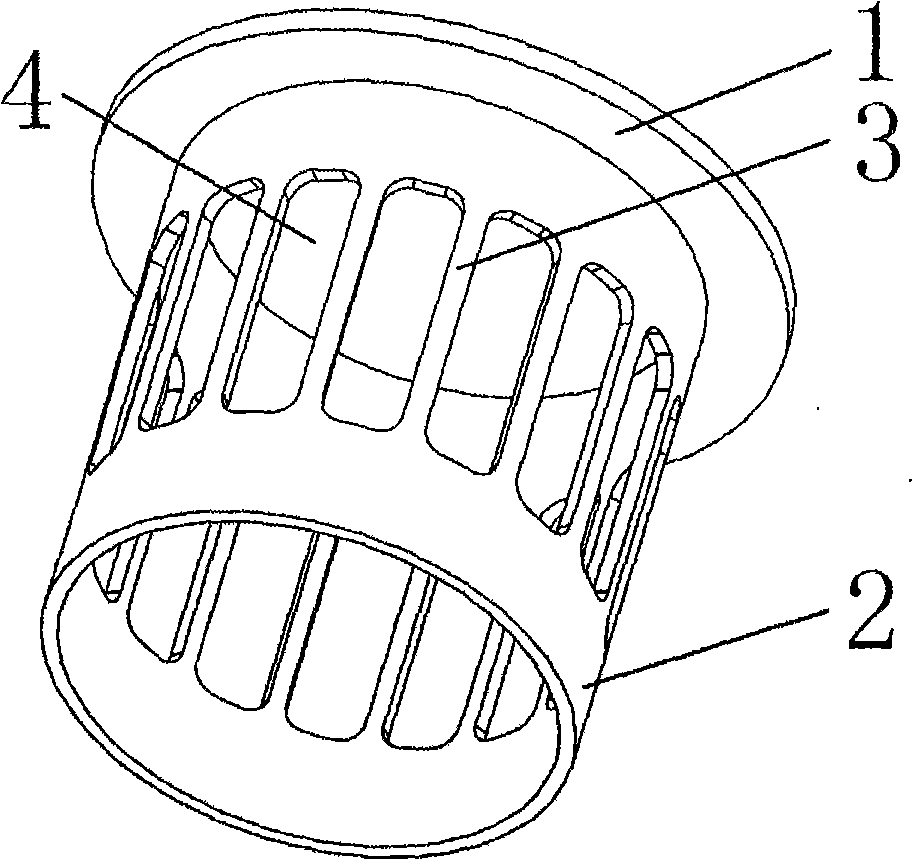

[0024] Embodiment 1: The squirrel-cage elastic support is a cantilever structure composed of a mounting edge 1 and a sleeve 2, and the mounting edge 1 and the sleeve 2 are integrally structured. One end of the squirrel-cage elastic support is fixed on the casing bearing seat through the installation side 1, and the other end is overhanging. The sleeve 2 is equipped with a bearing to support the rotor. The sleeve 2 is provided with a plurality of oval slots 4, and forms a plurality of cage bars 3 with different widths.

Embodiment 2

[0025] Example 2: Design of squirrel cage elastic bearing.

[0026] 1) Determine parameters such as sleeve size, material, volume and stiffness. See Table 1.

[0027] Table 1

[0028]

[0029] In Table 1, the stiffness coefficient indicates the size of the structural stiffness, and its value is the ratio of the total force acting on the entire elastic support to the total displacement of the cage bar in the direction of force.

[0030] 2) Establish the equivalent simplified model of the squirrel-cage elastic bearing.

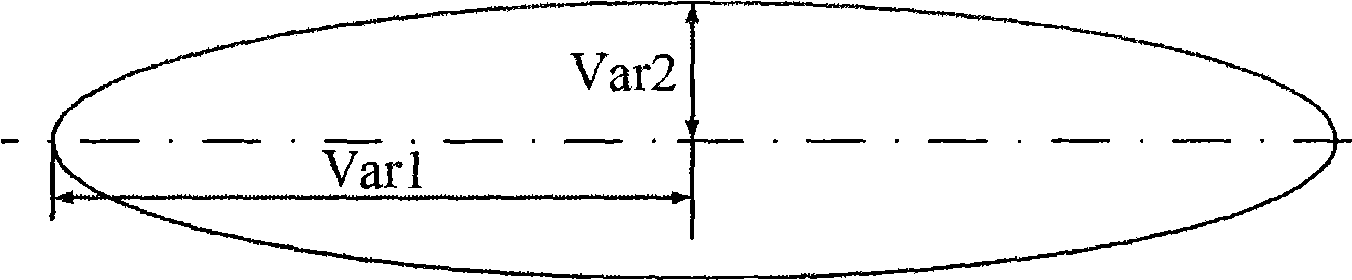

[0031] Utilizing the cyclic symmetry of the structure, the Shell63 unit is first selected in the general finite element analysis software ANSYS to establish the equivalent simplified geometric model of the unit cell of the squirrel-cage elastic bearing with an elliptical slot hole. The radius of the long and short axes is set as a variable parameter; then the unit cell model is arrayed along the circumference to generate a complete squirrel cage elastic be...

Embodiment 3

[0049] Example 3: Squirrel-cage elastic bearing design of SPEY high-pressure turbine front bearing.

[0050] 1) Determine the parameters such as the size, material, volume and stiffness of the squirrel-cage elastic bearing sleeve of the SPEY high-pressure turbine front bearing. See Table 4.

[0051] Table 4

[0052]

[0053] 2) Establish the equivalent simplified model of the squirrel-cage elastic bearing.

[0054] Utilizing the cyclic symmetry of the structure, the Shell63 element is first selected in the general finite element analysis software ANSYS to establish the equivalent simplified geometric model of the unit cell of the squirrel-cage elastic bearing with an elliptical slot hole. The long and short axis radius of the squirrel-cage elastic bearing is set as a variable parameter; then the unit cell model is arrayed along the circumferential direction to generate a complete squirrel-cage elastic bearing model and meshed to establish a finite element model of the squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com