Off-axis alignment system and alignment method

An alignment system, off-axis technology, applied in the direction of optics, instruments, and pattern surface photolithography, can solve problems such as prolonging the alignment time, silicon wafer alignment errors, and affecting the productivity of lithography machines. Achieve the effect of improving the alignment process and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to better understand the technical content of the present invention, specific embodiments are given and described as follows in conjunction with the accompanying drawings.

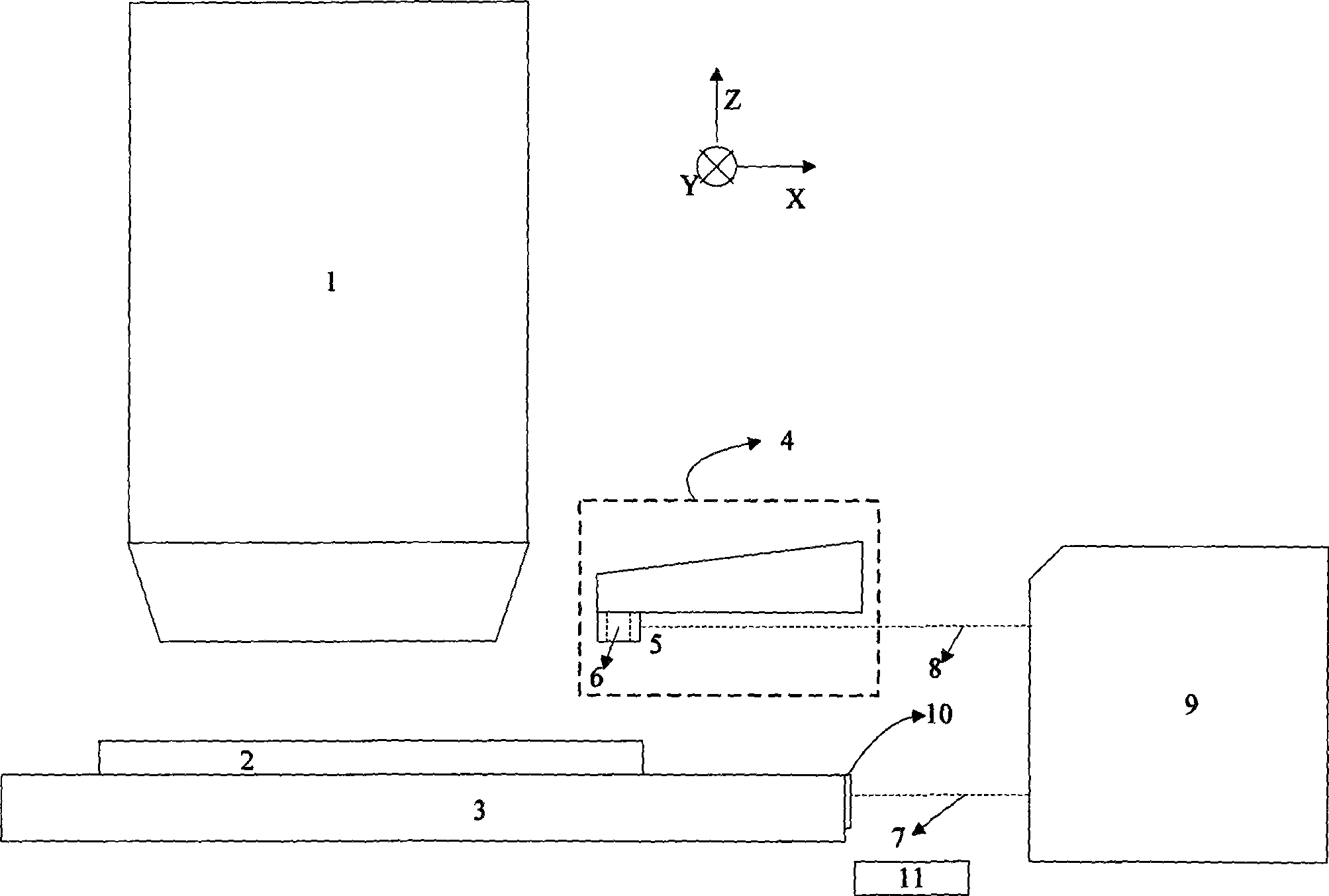

[0040] figure 1 Shown is a schematic structural diagram of a photolithographic apparatus with an off-axis alignment system in a preferred embodiment of the present invention.

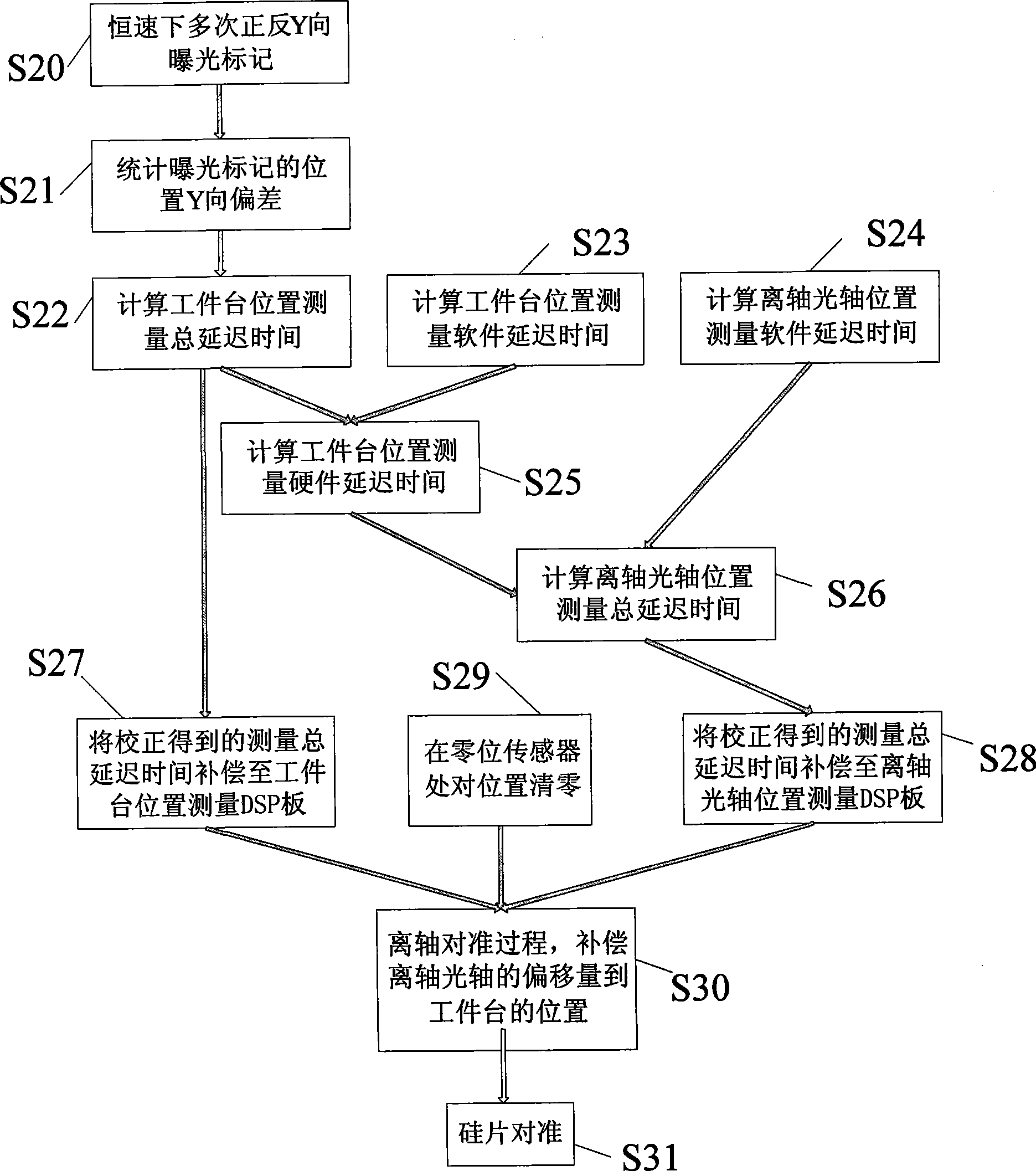

[0041] The invention monitors the relative change of the off-axis optical axis at the alignment time in real time through the laser interferometer, and compensates to the scanning position of the silicon chip mark, establishes the relationship between the coordinates of the silicon chip and the workpiece table, and quickly realizes the alignment of the silicon chip. It includes three parts: the structure layout of the off-axis measurement system, the error correction of the measurement system, the compensation algorithm and the alignment algorithm of the off-axis system.

[0042] figure 1 The shown lithography appa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com