Molecular distillating machine

A technology of molecular distillation and roller, applied in the direction of molecular distillation, etc., can solve problems such as waste of energy, decrease in separation efficiency, increase in heat transfer resistance, etc., to avoid thickening of the liquid film, improve the effect, and will not increase or increase big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

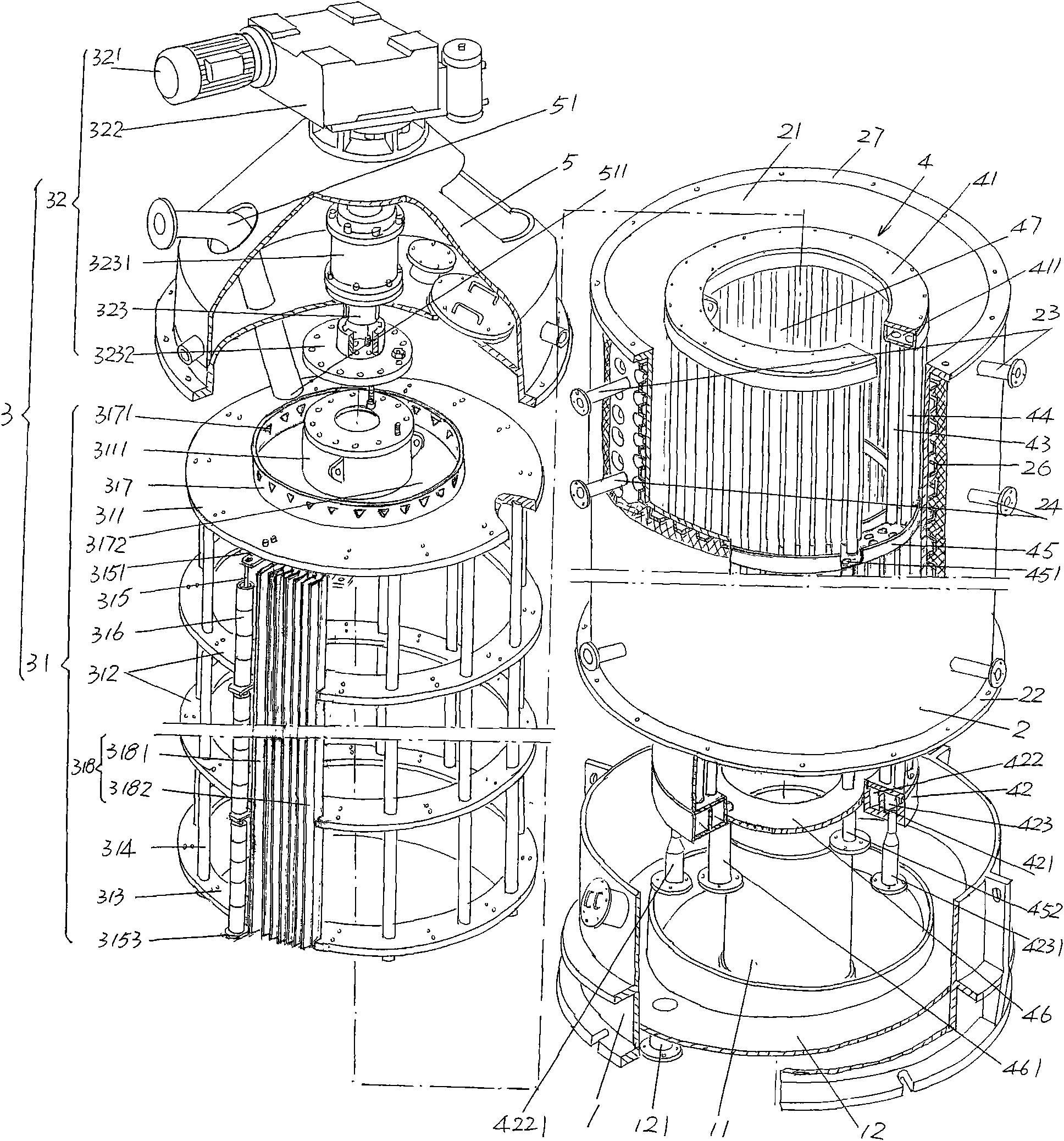

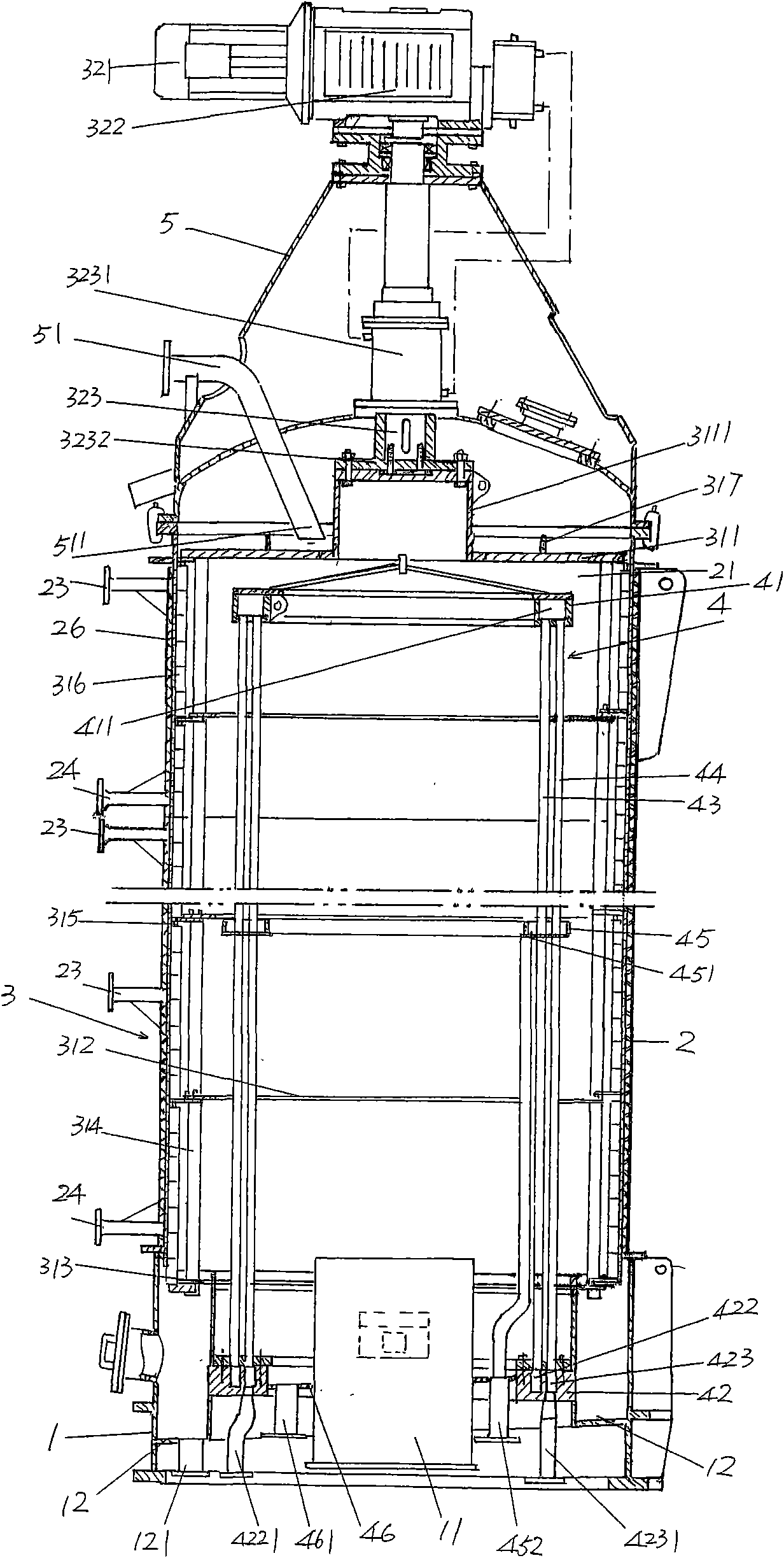

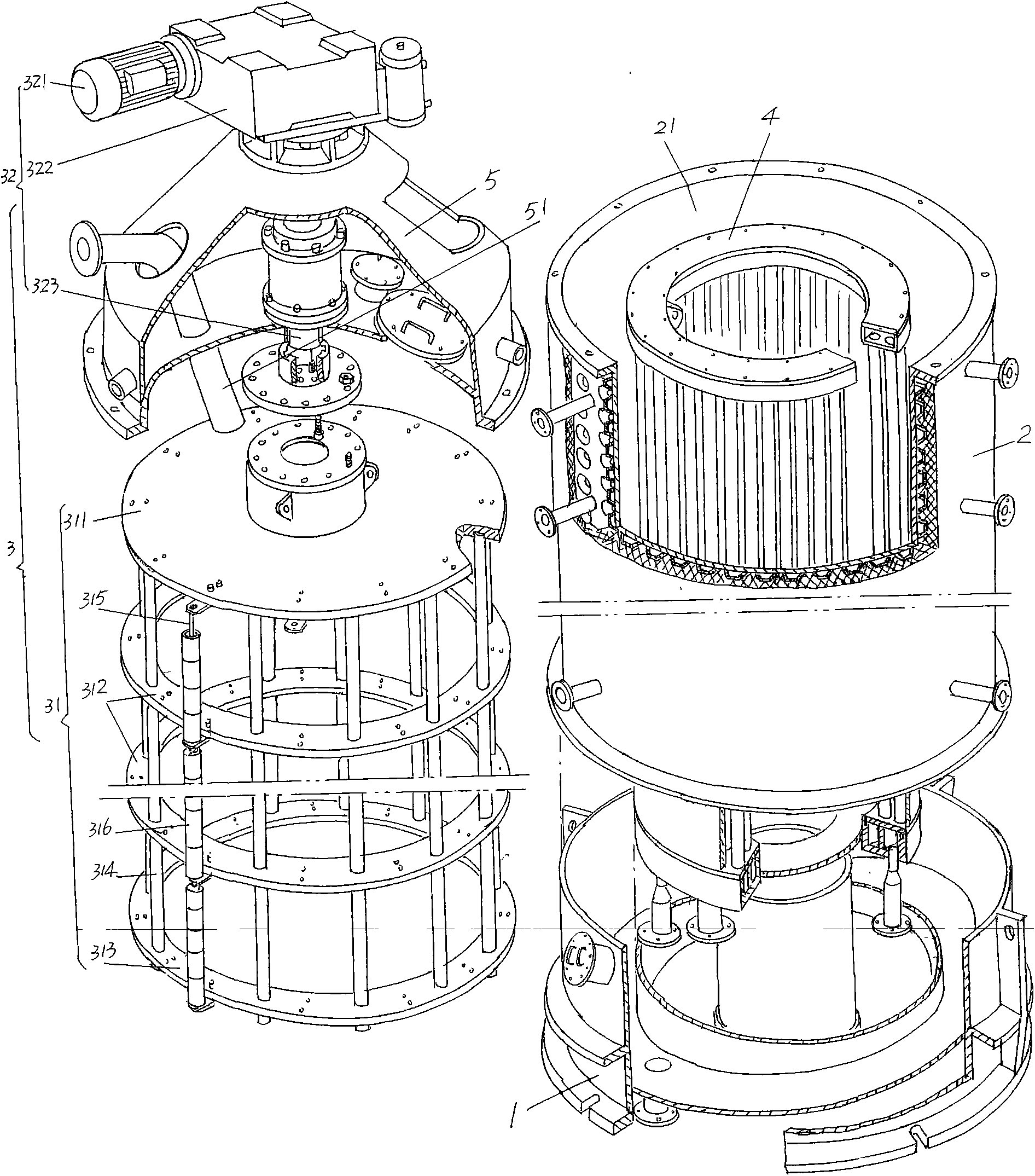

[0025] In order to enable the examiners of the patent office, especially the public, to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail below in conjunction with the accompanying drawings in the form of embodiments, but none of the descriptions of the embodiments is a description of the present invention. Restriction of the inventive solution, any equivalent transformation made according to the concept of the present invention which is only in form but not in substance shall be regarded as the scope of the technical solution of the present invention.

[0026] please see figure 1 and figure 2, the base 1 is provided, a vacuum tank is arranged in the center of the base 1, and an evaporator 2 is fixed to the upper edge of the base 1 by a fixing flange 22 at the bottom, the evaporator 2 is a honeycomb structure and An insulation layer 26 is provided on the outside, and a heating medium such as ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap