Deep processing treatment system for hot rolling strip steel

A technology of hot-rolled strip and processing system, applied in the field of deep-processing of strip, can solve the problems such as the inability to exert the production capacity advantage of the hot-rolled strip production line, the inability to replace medium plate products, and the lack of fundamental elimination, so as to achieve a wide range of steel types. , saving investment, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

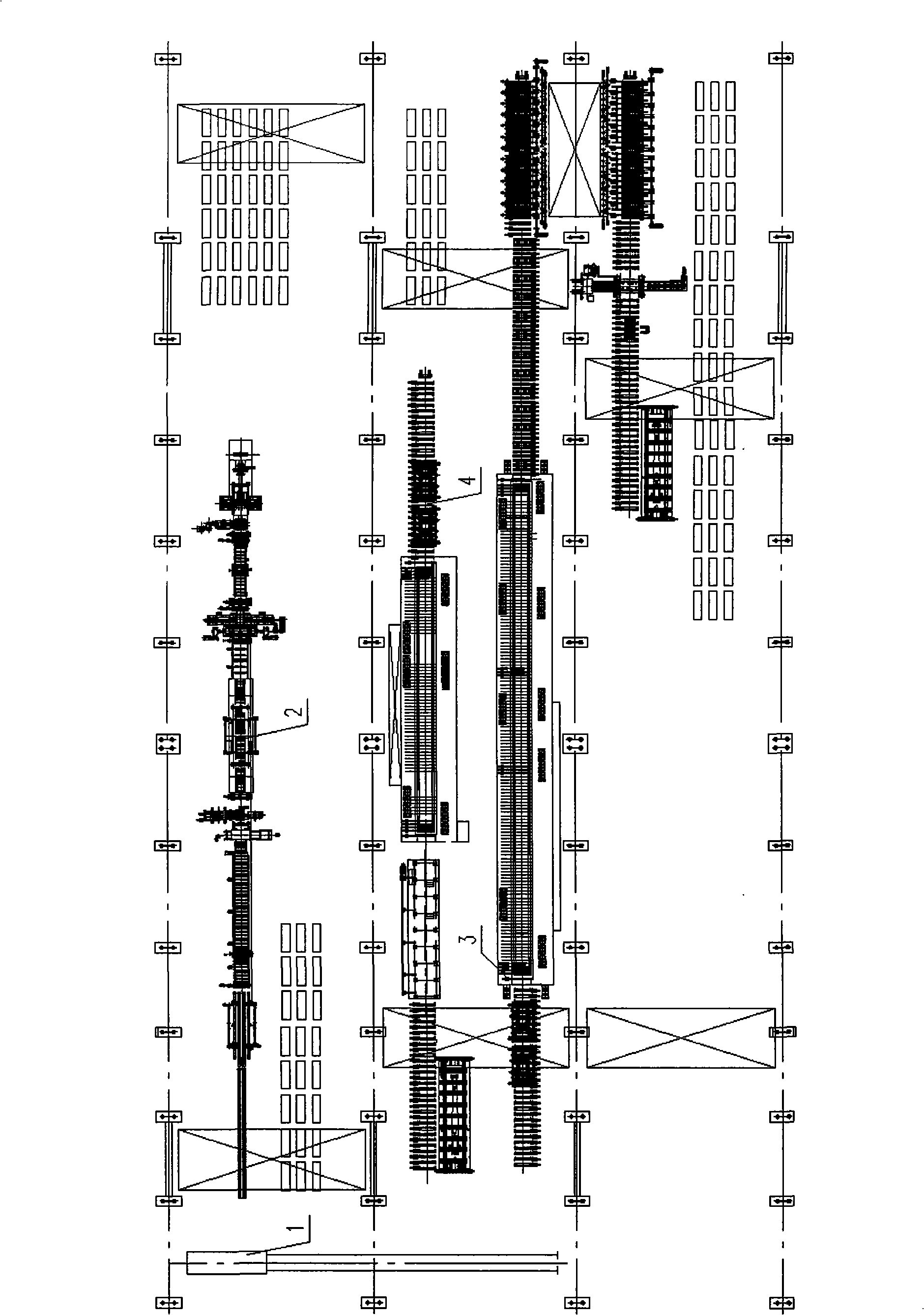

[0026] Such as figure 1 As shown, a hot-rolled strip deep processing system combining Kaiping unit 2 and a heat treatment line includes an independent hot-rolled strip Kaiping unit and a heat treatment line. The heat treatment line includes a quenching heat treatment line 4 and / or a normalizing heat treatment line 3 . It is characterized in that the hot-rolled strip flattening unit 2 and the heat treatment line are arranged in the adjacent finished span, and the flattened flats produced by the flattening unit are transported to the heat treatment line by the flatbed trolley 1 or other transportation methods for quenching or tempering treatment.

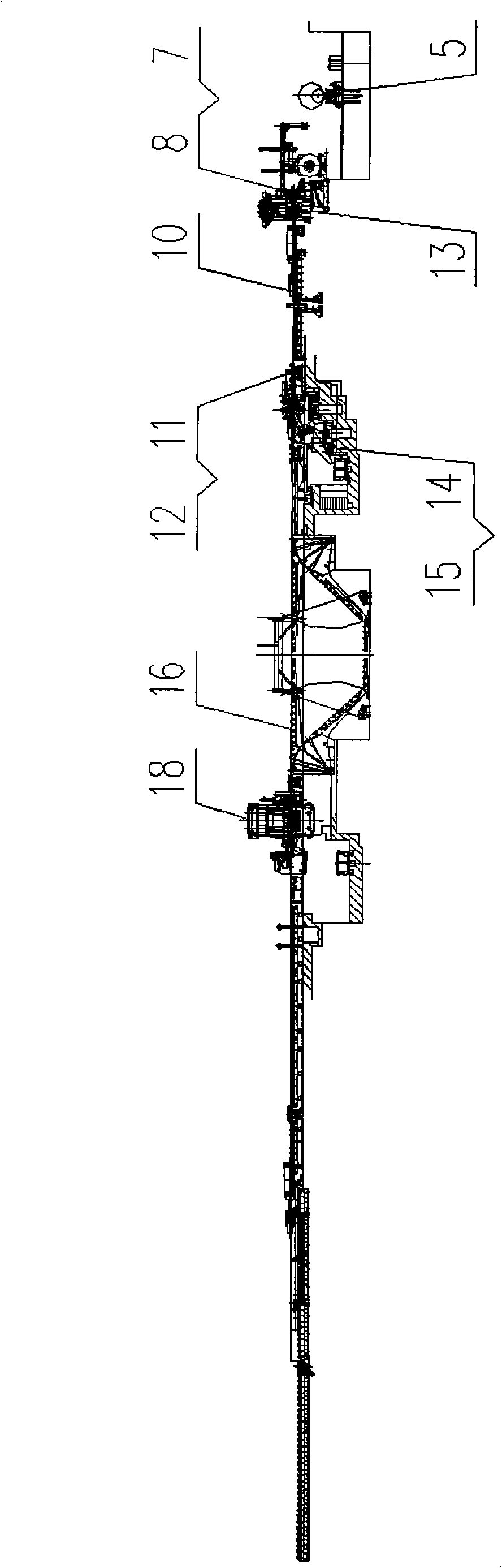

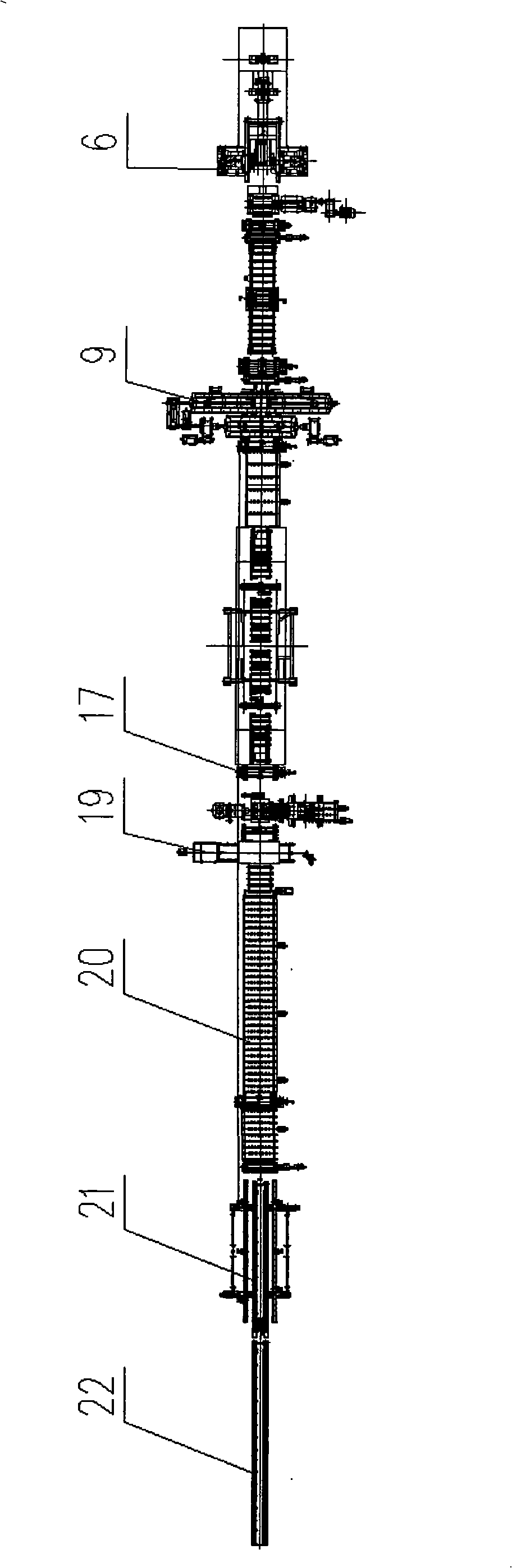

[0027] Kaiping unit such as figure 2 , image 3 As shown, the crane puts the steel coil on the 5 saddles of the winding trolley for storing the steel coils. There are 2 saddles in total, and the steel coil straps are manually opened at the second station. Then, the steel coil is sent into the uncoiler 6 through the winding trolley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com