Preparation method of superstructure aragonite calcium carbonate crystal

A technology of calcium carbonate and superstructure, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of complex preparation process and difficulty in large-scale production, and achieve the effect of simple preparation method, easy control of conditions, and high crystal phase purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

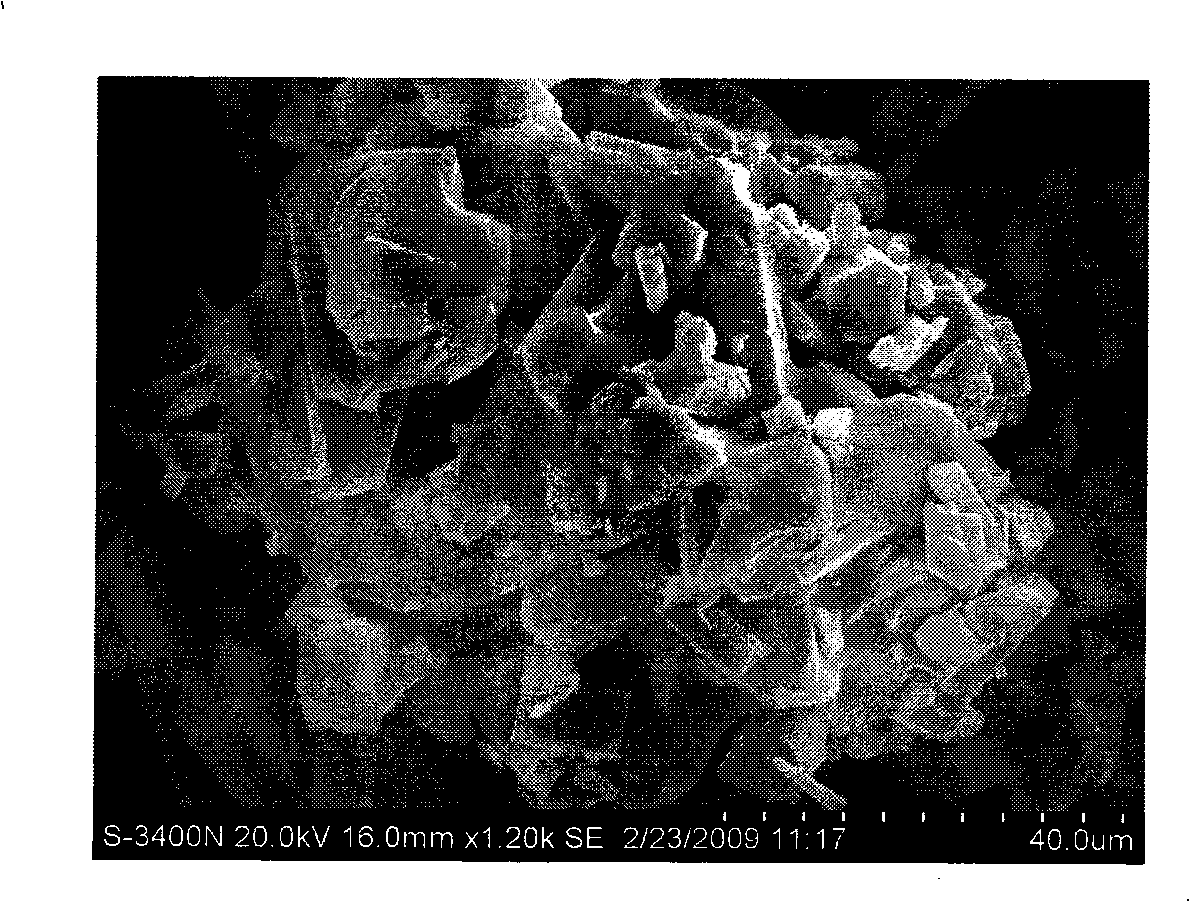

Embodiment 1

[0023] 1) Add 2g of PAANa into 998g of deionized water, stir and dissolve at 30°C to obtain a PAANa aqueous solution with a concentration of 0.2wt%;

[0024] 2) Add 0.055g of calcium chloride to the PAANa aqueous solution and stir to dissolve, then add 0.03g of urea and stir to dissolve, transfer the mixed solution (the concentration of calcium chloride is 0.5mmol / L) to a sealed container, and place at a constant temperature In an oven, keep the temperature at 60° C. for 24 hours. After the constant temperature is over, filter and separate the mixed solution, wash, and dry to obtain white superstructure aragonitic calcium carbonate crystals.

Embodiment 2

[0026] 1) Add 10g of PAANa into 990g of deionized water, stir and dissolve at 60°C to obtain a PAANa aqueous solution with a concentration of 10wt%;

[0027] 2) Add 5.55g of calcium chloride to the PAANa aqueous solution and stir to dissolve, then add 24.0g of urea and stir to dissolve, transfer the mixed solution (the concentration of calcium chloride is 50mmol / L) to a sealed container, and place in a constant temperature oven In the process, keep the temperature at 110° C. for 4 hours. After the constant temperature is over, the mixed solution is centrifuged, washed, and dried to obtain white superstructure aragonite calcium carbonate crystals.

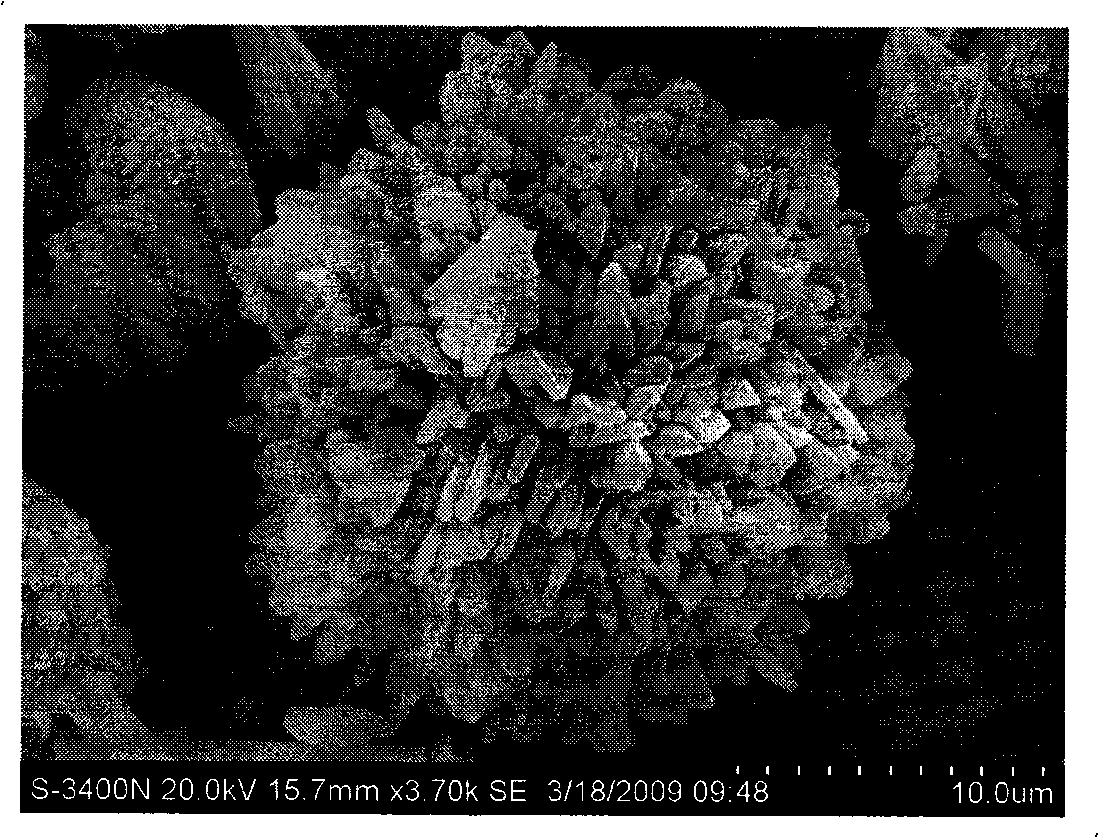

Embodiment 3

[0029] 1) Add 6g of PAANa into 994g of deionized water, stir and dissolve at 40°C to obtain a PAANa aqueous solution with a concentration of 6wt%;

[0030] 2) Add 2.22g of calcium chloride to the PAANa aqueous solution and stir to dissolve, then add 3.6g of urea and stir to dissolve, transfer the mixed solution (the concentration of calcium chloride is 20mmol / L) to a sealed container, and place in a constant temperature oven In the process, keep the temperature at 90° C. for 18 hours. After the constant temperature is over, the mixed solution is separated by filtration, washed, and dried to obtain white superstructure aragonite calcium carbonate crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com