Method for manufacturing self-cleaning glass plated with photocatalysis layer and antibacterial metal ions

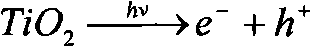

A technology of antibacterial glass and manufacturing method, which is applied in the field of self-cleaning photocatalytic antibacterial glass and its production technology, can solve the problems of the research on inorganic antibacterial materials, which are in the ascendant, and achieve the effects of easy quality control, high hardness, and strong response to visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Clean the glass surface with dilute hydrochloric acid, then clean it with deionized water, and dry it in an oven at 100°C.

[0024] 2. Use titanate, ethanol, water, hydrochloric acid, and triethanolamine as main components, and prepare titanium dioxide sol at a mass ratio of 1:5~20:2~5:0.1~1:0.2~2.

[0025] 3. Add Ag nanometer metal ions to the titania sol with a mass fraction of 0.2%.

[0026] 4. Place the cleaned and dried glass piece in the above solution, and lift it out of the solution at a speed of 1 mm / s after standing for 5 minutes.

[0027] 5. The coated glass is dried at 100°C, and then sintered in a muffle furnace at 700°C for 1 hour.

[0028] 6. Cool the coated glass treated in the above steps to obtain the photocatalytic antibacterial glass containing nano-silver.

Embodiment 2

[0030] 1. Clean the glass surface with dilute hydrochloric acid, then clean it with deionized water, and dry it in an oven at 100°C.

[0031] 2. Use titanate, ethanol, water, hydrochloric acid, and triethanolamine as main components, and prepare titanium dioxide sol at a mass ratio of 1:5~20:2~5:0.1~1:0.2~2.

[0032] 3. Add 0.2% Ag, 0.2% Zn nanometer metal ions into the titania sol.

[0033] 4. Place the cleaned and dried glass piece in the above solution, and lift it out of the solution at a speed of 1 mm / s after standing for 5 minutes.

[0034] 5. The coated glass is dried at 100°C, and then sintered in a muffle furnace at 700°C for 1 hour.

[0035] 6. Repeat steps 4-5 for the glass that has been coated with a layer of film, that is, place the glass piece again in the titanium dioxide sol containing metal ions, dip and pull, dry at 100°C, and then sinter in a muffle furnace at 700°C for 1 hour. Repeat this step twice to obtain glass coated with three layers of photocatalyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com