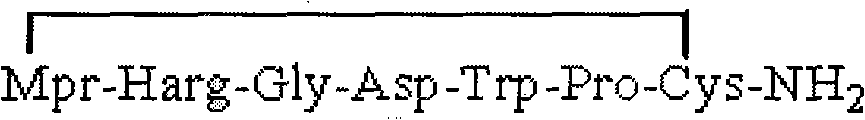

Method for purifying Eptifibatide

A technology of eptifibatide and phase B, applied in the field of HPLC, can solve the problem of not finding large-scale production and purification process, and achieve the effect of high yield purification and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. The first step of purification: Take a Buchner funnel of appropriate size, put a layer of filter paper, then spread a layer of diatomaceous earth with a thickness of 2cm-3cm, and put a layer of filter paper on top. Pour the oxidized solution of eptifibatide into the funnel for suction filtration under reduced pressure, and collect the filtrate for later use.

[0024] 2. The second step of purification: Purification conditions: chromatographic column: a chromatographic column with alkylsilane bonded silica gel as the stationary phase, and the diameter and length of the column are: 5cm×25cm. Mobile phase: A phase: 0.1% trifluoroacetic acid aqueous solution; B phase: chromatographically pure acetonitrile. Flow rate: 70-80ml / min. Detection wavelength: 280nm. Gradient: B%: 15% ~ 30% (30min), the injection volume is 1.0-1.2g.

[0025] Purification process: equilibrate the chromatographic column with mobile phase A and load the sample, the sample volume is 2.0-2.4L sampl...

Embodiment 2

[0029] 1. The first step of purification: Take a Buchner funnel of appropriate size, put a layer of filter paper, then spread a layer of diatomaceous earth with a thickness of 2cm-3cm, and put a layer of filter paper on top. Pour the oxidized solution of eptifibatide into the funnel for suction filtration under reduced pressure, and collect the filtrate for later use.

[0030] 2. The second step of purification: Purification conditions: chromatographic column: a chromatographic column with alkylsilane bonded silica gel as the stationary phase, and the diameter and length of the column are: 15cm×25cm. Mobile phase: A phase: 0.1% trifluoroacetic acid aqueous solution; B phase: chromatographically pure acetonitrile. Flow rate: 400-500ml / min. Detection wavelength: 280nm. Gradient: B%: 15% to 30% (30min). The injection volume is 15-18g.

[0031] Purification process: equilibrate the chromatographic column with mobile phase A and load the sample, the sample volume is 15-20L samp...

Embodiment 3

[0035] 1. The first step of purification: Take a Buchner funnel of appropriate size, put a layer of filter paper, then spread a layer of diatomaceous earth with a thickness of 2cm-3cm, and put a layer of filter paper on top. Pour the oxidized solution of eptifibatide into the funnel for suction filtration under reduced pressure, and collect the filtrate for later use.

[0036] 2. The second step of purification: Purification conditions: chromatographic column: a chromatographic column with alkylsilane bonded silica gel as the stationary phase, and the diameter and length of the column are: 30cm×25cm. Mobile phase: A phase: 0.1% trifluoroacetic acid aqueous solution; B phase: chromatographically pure acetonitrile. Flow rate: 1500-2000ml / min. Detection wavelength: 280nm. Gradient: B%: 15% to 30% (30min). The injection volume is 60-80g.

[0037] Purification process: equilibrate the chromatographic column with mobile phase A and load the sample, the sample volume is 60-80L sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com