Fiber grating inclination sensor of temperature self-compensation type

A technology of tilt sensor and optical fiber grating, which is applied in the field of tilt angle devices, can solve problems such as troublesome, small angle change measurement accuracy is not high, and achieve the effect of simple process, high durability, and convenient layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

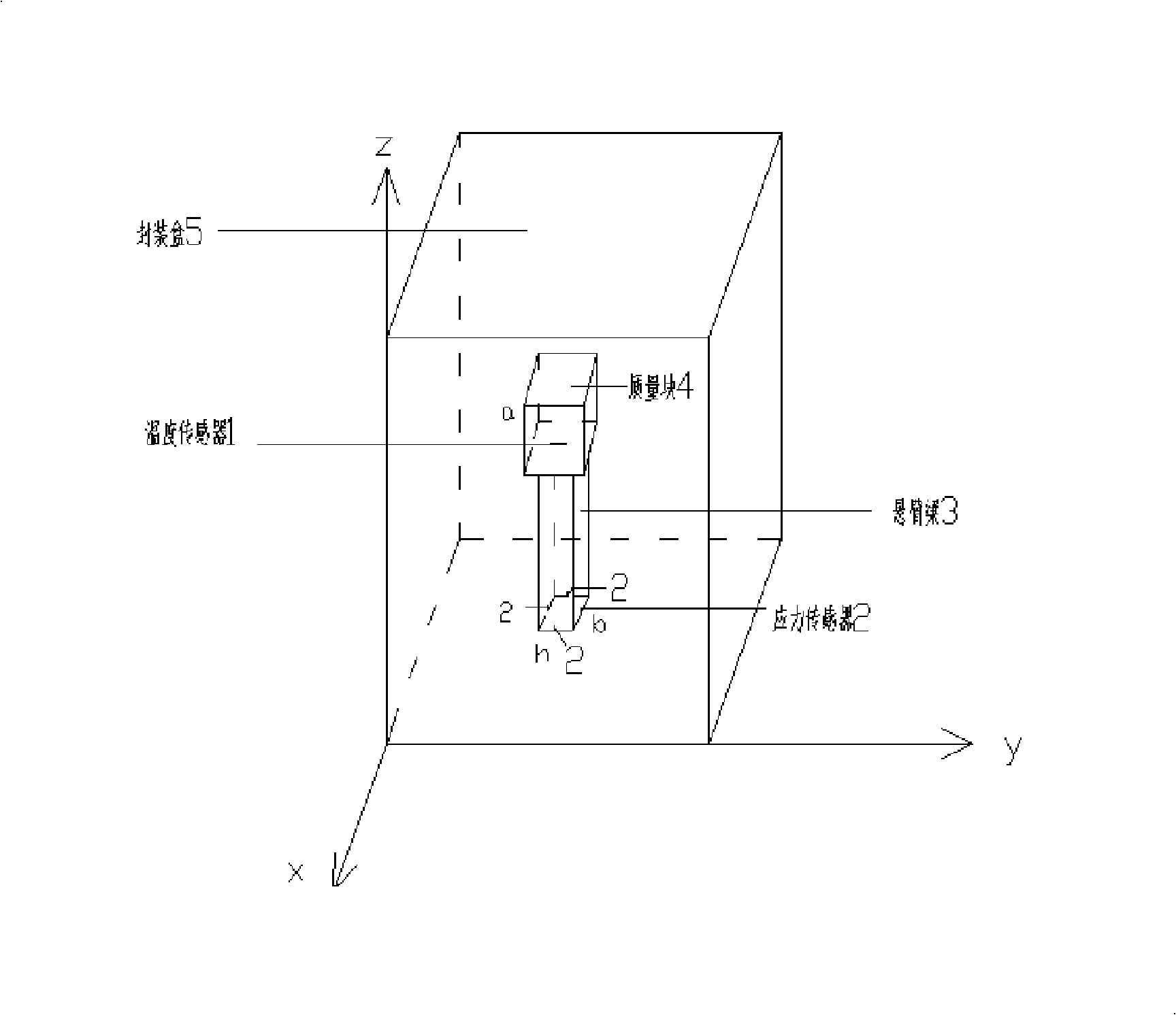

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the technical solution and the drawings.

[0014] Place the packaging box 5 on the surface of the inclined structure to be measured. When the packaging box 5 and the cantilever rod 3 are tilted, the cantilever rod in the packaging box 5 will generate a bending moment, which will cause the strain change of the elastic cantilever rod. Fiber grating strain sensor 2 The strain change is monitored, and the measurement signal is transmitted to the outside equipment acquisition system through the optical fiber. At the same time, the fiber grating temperature sensor 1 arranged on the mass 4 monitors the temperature to realize the temperature self-compensation of the measurement system. So as to realize the measurement of tilt angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com