Method for manufacturing fiber grating and sensor using same

A fiber grating and sensor technology, which is applied in the field of sensing, can solve the problems of being unable to meet the actual engineering needs of simultaneously measuring the bending curvature and distinguishing the bending direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

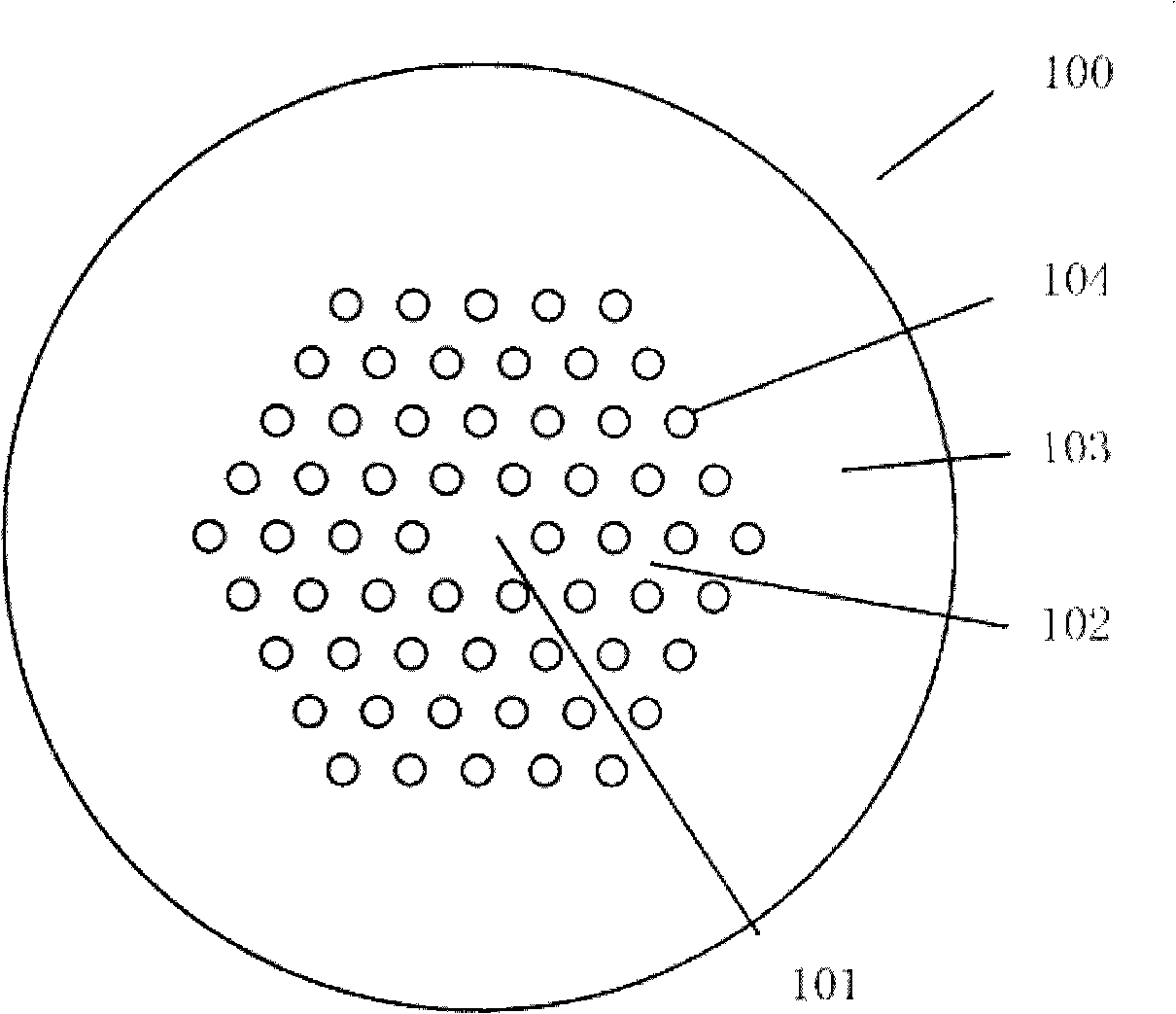

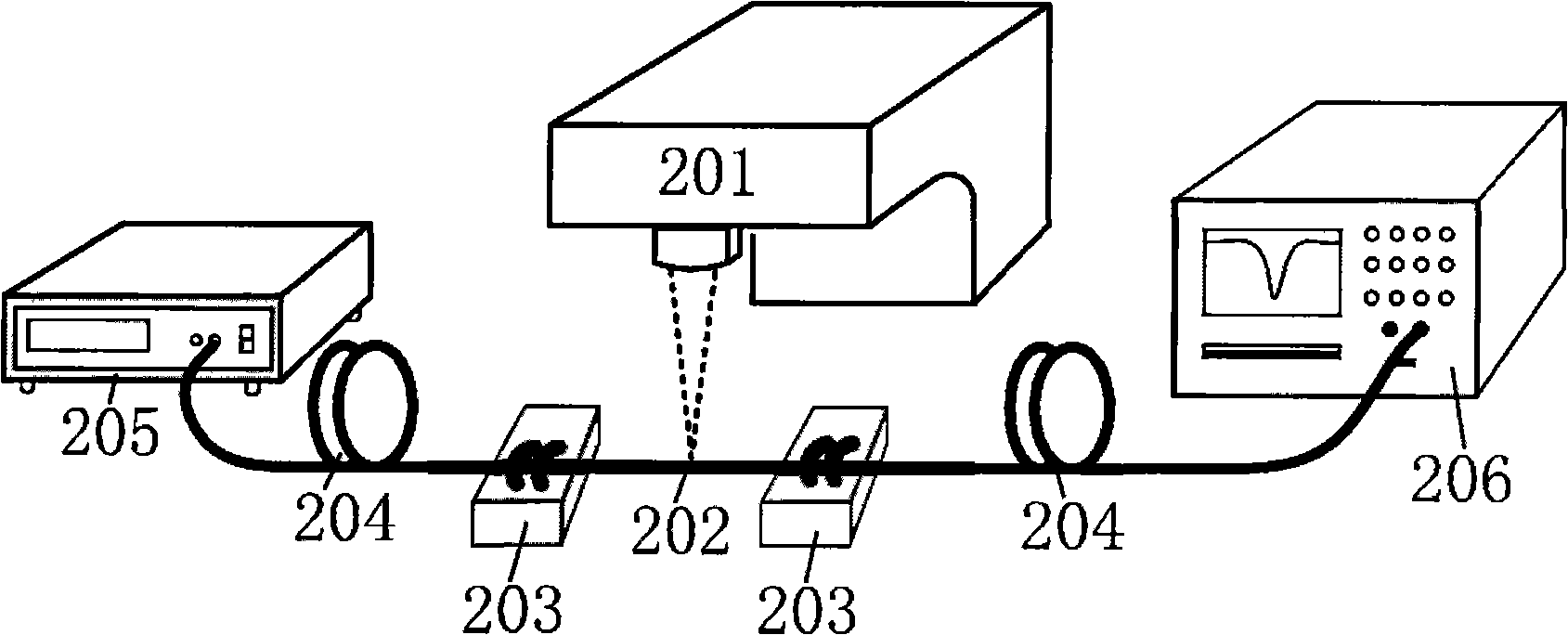

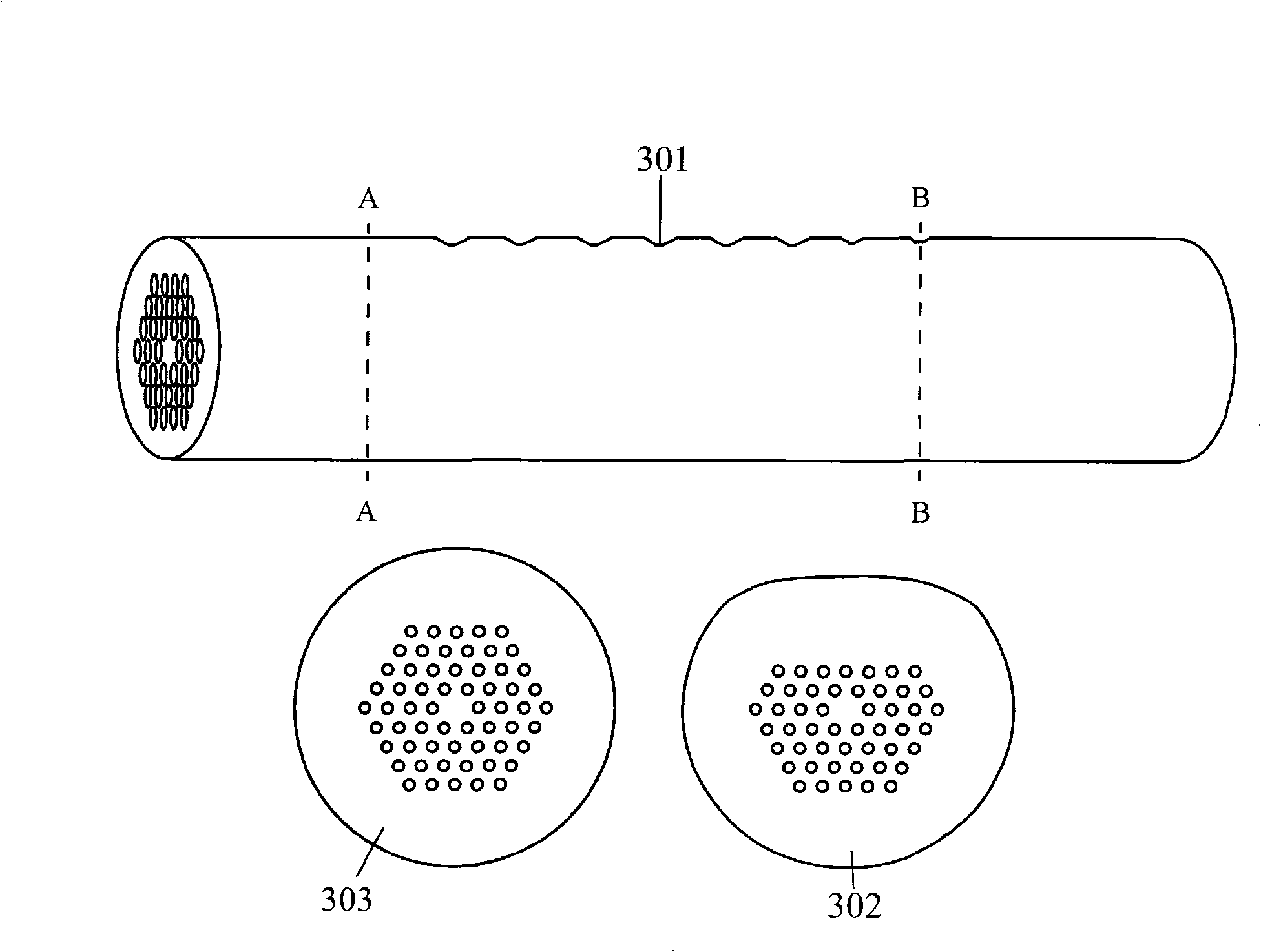

[0046] Such as Figure 5 As shown, the photonic crystal fiber used in Embodiment 1 of the present invention is the LMA10 fiber of Crystal-FiberA / S, and its cross section is as follows Figure 5 As shown in a, it is made of pure quartz and is made by "stack-drawing" method. The optical fiber contains four layers of air holes, and the air holes are regularly arranged in a triangular array. The air hole diameter is 3.5 μm, and the air hole spacing is 7.8 μm. Since the ratio of air hole diameter to spacing is less than 0.45, the fiber only supports single-mode transmission at any wavelength. The long period fiber grating 702 is made of CO 2 The lasers are fabricated in photonic crystal fibers. The energy parameters and scanning trajectory of the laser pulse are controlled by a computer. CO 2 The repetition rate of the laser is 1000Hz, the average output power is 0.1W, and the Q-switching time is 4.2μs. The laser spot scanning speed is 3.2mm / s. The period of the fiber grati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com