Motor winding enamelled wire, iron core separation device and separation method

A technology of motor windings and separation devices, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators, etc. It can solve the problems of no dust recovery, cumbersome operations, and large and complex devices, so as to adapt to a wide range of motors and separate processes. Safe and efficient separation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

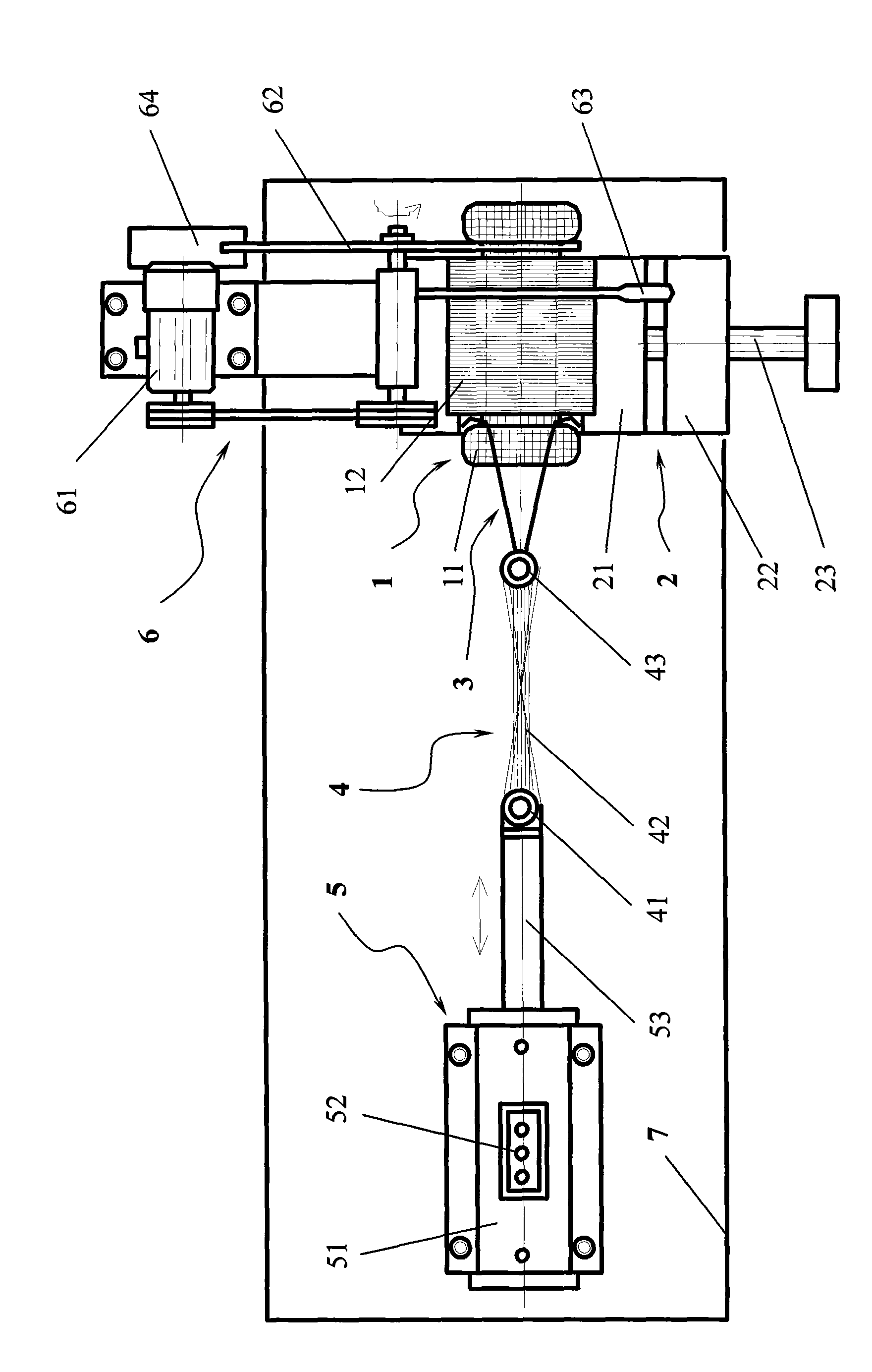

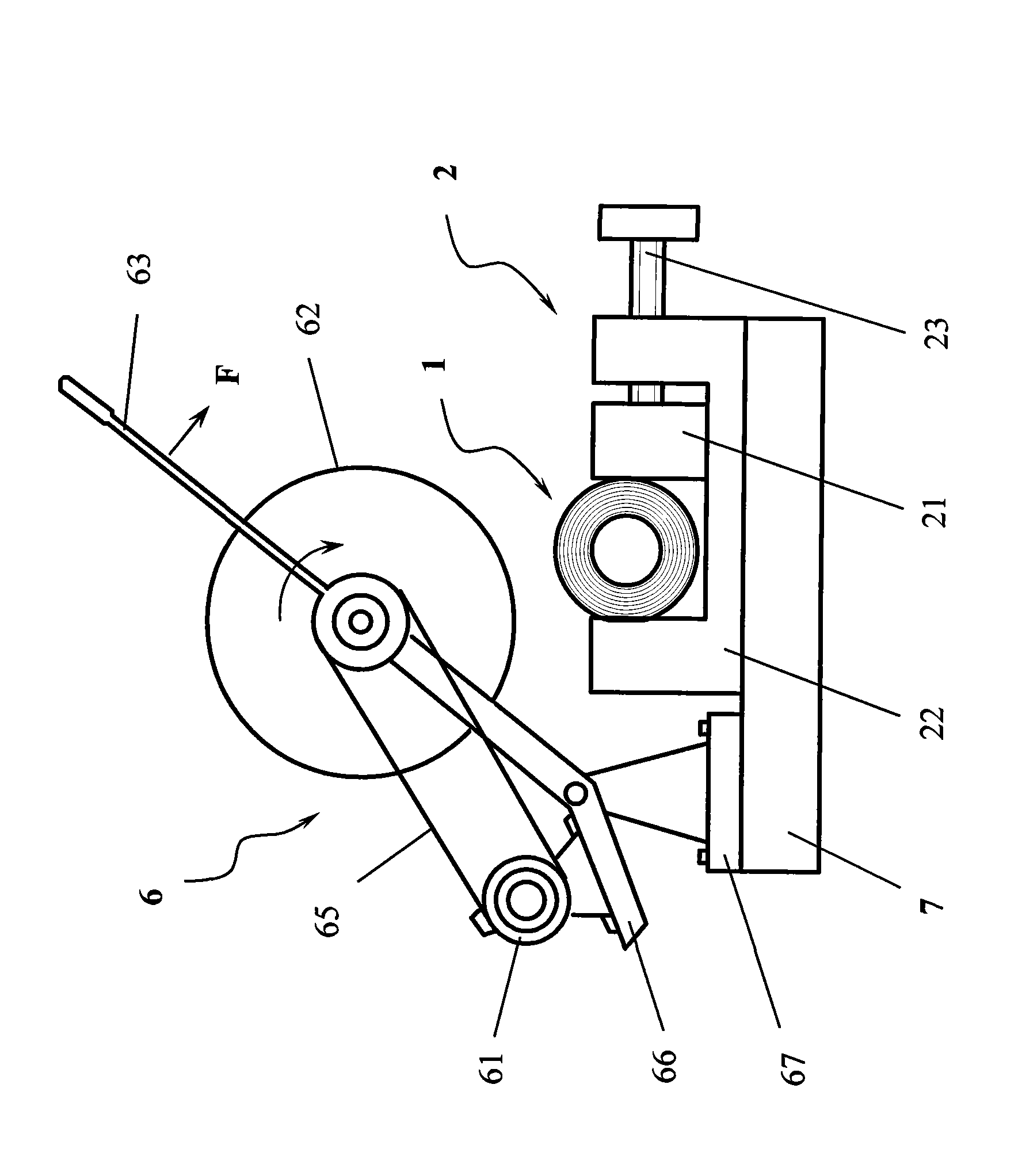

[0023] see figure 1 , a horizontal working platform 7 is set, on which the vise 2 for clamping the winding iron core 1 is fixed, and on one side of the vise 2, a cutting machine 6 is set, and the grinding wheel sheet 62 on the cutting machine 6 is in the winding enameled wire 11 On the right end position, the knife edge of the grinding wheel sheet 62 is parallel to the end face of the winding enameled wire 11; on the left side of the winding iron core 1, a cylinder 5 is arranged along the axial direction of the winding iron core 1, and the telescopic piston rod 53 in the cylinder 5 The front end of the bar is connected to the hook 3 that can be embedded in the left end of the winding enameled wire 11 through the steel wire rope 42 in the drag cable 4 .

[0024] figure 2 As shown, the flat-nose pliers 2 are composed of a pliers body 22 , a slider 21 and a screw rod 23 , and the rotation of the screw rod 23 pushes the slider 21 , so that the winding iron core 1 is clamped in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com