Power assembly system

A powertrain and power coupling technology, applied in the direction of power units, electric power units, hybrid vehicles, etc., can solve the problems of complex topology layout and control, difficult to achieve transmission ratio, etc., to facilitate vehicle control and calibration, design and processing difficulty Low, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention is described below through preferred implementation, and the accompanying drawings are for reference. There may be many modifications, changes or variations to the present invention without departing from the scope or spirit of the essential characteristics of the invention.

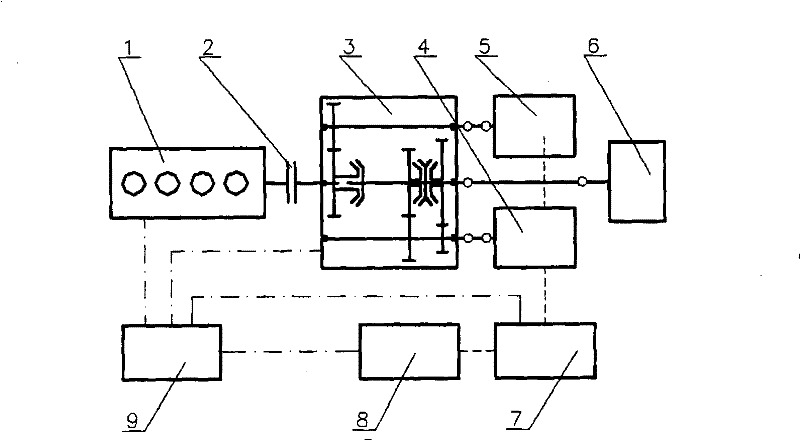

[0030] The present invention relates to a hybrid powertrain system for a hybrid vehicle, figure 2 It is a structural schematic diagram of an embodiment of the present invention. As shown in the figure, the powertrain system has a power coupling device 3, the engine 1 is located on the side of the power coupling device 3, and its power is transmitted to the power coupling device 3 through the engine clutch 2, and the first and second motors 5, 4 are arranged On the other side of the power coupling device 3 . The output shaft of the power coupling device 3 is connected to the drive axle 6 to transmit power to the drive axle 6 .

[0031] The power b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com